(* = shaped).

advertisement

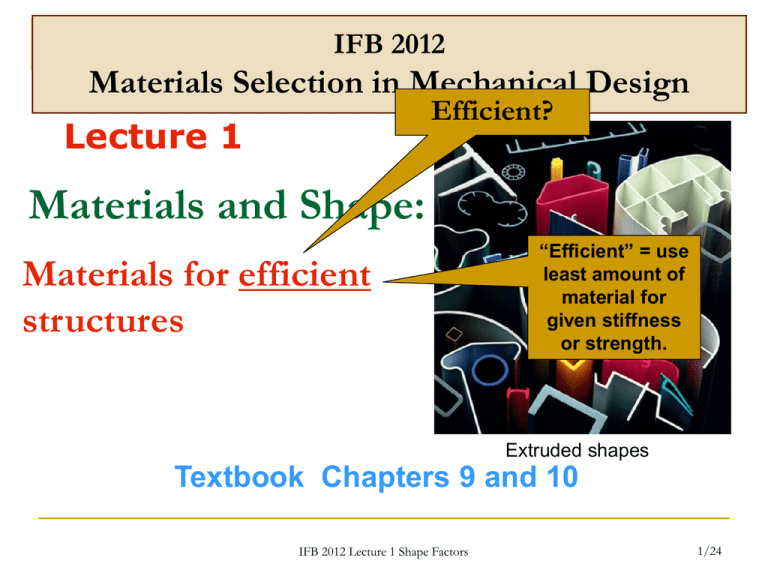

IFB 2012 Materials Selection in Mechanical Design Efficient? Lecture 1 Materials and Shape: Materials for efficient structures “Efficient” = use least amount of material for given stiffness or strength. Extruded shapes Textbook Chapters 9 and 10 IFB 2012 Lecture 1 Shape Factors 1/24 Shape and Mechanical Efficiency • Section shape becomes important when materials are loaded in bending, in torsion, or are used as slender columns. Is shape important for tie rods? • Examples of “Shape”: • Shapes to which a material can be formed are limited by the material itself. Shapes from: http://www.efunda.com/math/areas/RolledSteelBeamsS.cfm IFB 2012 Lecture 1 Shape Factors 2/24 Certain materials can only be made with certain shapes: what is the best material/shape combination (for each loading mode) ? Extruded shapes IFB 2012 Lecture 1 Shape Factors 3/24 Shape efficiency: bending stiffness pp.bh 248-249 3 I 2 Define a standard reference section: a solid square, area A = b 12 S Io b 4 C 1 EI 3 Area A is constant 2 12 L Define shape factor for elastic bending, measuring efficiency, as Shaped sections Neutral reference section F Ao 12 Area Ao = b2 modulus E unchanged b b So C E I0 L S 3 e S So E I E Io I Io 12 I 2 Ao 12 L I A C E I 2 IFB 2012 Lecture 1 Shape Factors 3 Ao = A 4/24 bending stiffness e S So EI E Io I Io 12 I A 2 A shaped beam of shape factor for elastic bending, e = 10, is 10 times stiffer than a solid square section beam of similar cross section area. IFB 2012 Lecture 1 Shape Factors 5/24 Properties of the shape factor e = 2 Rectangular Sections The shape factor is dimensionless -- a pure number. It characterises shape, regardless of size. I-sections e 10 Circular tubes e 15 Increasing size at constant shape = constant SF These sections are φe times stiffer in bending than a solid square section of the same cross-sectional area IFB 2012 Lecture 1 Shape Factors 6/24 Shape efficiency: bending strength p. 254 Define a standard reference section: a solid square, area A = b2 Neutral reference section yield strength unchanged Area A is constant factor for the onset of plasticity b M f 0 Io ym b 3 6 3/2 M b A0 Z 6 I * 0 Z 0 ym f * Define shape Area A = b2 Zo M M I f fo * Z o * Z Zo IFB 2012 Lecture 1 Shape Factors * Z (failure), yI measuring efficiency, as m I * Z M f ym Z I ym section modulus , Z y max * f 6 * Z A 3/2 A = Ao 7/24 * bending strength f M M f fo Z Z o * * Z Zo 6 Z A 3/2 A shaped beam of shape factor for bending strength, f = 10, is 10 times stronger than a solid square section beam of similar cross section area. IFB 2012 Lecture 1 Shape Factors 8/24 Tabulation of shape factors (elastic bending) p. 252 Section shape h Area A m bh Second moment I, m 4 Elastic shape factor b h3 12 h b 3 a b 4 3a b b 2a ab e I Io I bh 1 h 12 2 12 2 2 A 12 b h b 3 Second moment of section, I A2 = Ao2 2b t 2ri 2ro (ro2 ri2 ) 2r t 4 4 (ro ri ) 4 r3 t t h 2 t ( h b) (h, b t ) 1 3 b h t (1 3 ) 6 h 3 r t (r t ) e I Io 12 I A r t 3 2 12 ( 2 rt ) 2 3r t r t 1 h (1 3b / h ) 2 t (1 b / h )2 (h , b t b t hi ho b (h o h i ) 2bt (h , b t ) b b 3 (h o h 3i ) 12 1 b t h o2 2 t h 2t 2 t ( h b) (h, b t ) 1 3 b h t (1 3 ) 6 h 3 h o2 2 bt (h , b t ) 1 h (1 3b / h ) 2 t (1 b / h )2 (h , b t ) b IFB 2012 Lecture 1 Shape Factors 9/24 Comparison of shapes done so far for given material (E, y) and constant cross section area, A. Interesting, but not very useful. This is a case of Material Substitution at constant structural stiffness or strength, allowing for differences in shape How to compare different materials and Example: compare Steel scaffoldings different shapes at: with Bamboo scaffoldings Constant structural stiffness, S ? Constant failure moment, Mf ? IFB 2012 Lecture 1 Shape Factors 10/24 Indices that include shape (1): minimise mass at constant stiffness allowing for changes in shape p. 265-270 F F L Function Beam (shaped section). Objective Minimise mass, m, where: Area A m AL Constraint Bending stiffness of the beam S: S CEI L 3 Trick to bring the Shape Factor in ? e I Io 12 A I e 12 I A 2 2 A m L Eliminating A from the eq. for the mass gives: 12 S L m C 5 1/ 2 E 1 / 2 e L m = mass A = area L = length = density b = edge length S = stiffness I = second moment of area E = Youngs Modulus Shape factor part of the material index e E 1/ 2 Chose materials with largest IFB 2012 Lecture 1 Shape Factors 11/24 Indices that include shape (2): minimise mass at constant strength p . 311 F Function Beam (shaped section). Objective Minimise mass, m, where: F L Area A m AL Constraint Bending strength of the beam Mf: M f I Z * * ym Trick to bring the Shape Factor in ? f Z Z 6 Zo A 3/2 Z fA 6 3/2 A m L m = mass A = area L = length = density Mf = bending strength I = moment of section E = Young’s Modulus Z = section modulus L Eliminating A from the equation for m gives: m 6 M f 2/3 L 2/3 f * f * 2/3 Chose materials with largest Shape factor part of the material index IFB 2012 Lecture 1 Shape Factors 12/24 From Introduction: Demystifying Material Indices (elastic bending) Given shape, Same shape, Material 2, same S Material 1, given S 12 S L m 1 C 5 1/ 2 1 1 / 2 E1 2 1 / 2 m1 E2 m2 12 S L m 2 C 5 E 11 / 2 1 1/ 2 2 1 / 2 E2 M1 M2 For given shape, the reduction in mass at constant bending stiffness is determined by the reciprocal of the ratio of material indices. Same conclusion applies to bending strength. IFB 2012 Lecture 1 Shape Factors 13/24 Demystifying Shape Factors (elastic bending) Shaped to φe, same material, same S F Square beam, mo , given S L 12 S L mo C 5 1/ 2 ms mo F L 1 1/ 2 E 1 1 1/ 2 ( E ) 1 12 S L m s C 5 E11 / 2 1 1 1/ 2 1/ 2 1 E 1 / 2 e 1 EXAM QUESTION Is the cross section area constant when going from mo to ms? Shaping (material fixed) at constant bending stiffness reduces the mass of the component in proportion to e-1/2 . Optimum approach: simultaneously maximise both M and . IFB 2012 Lecture 1 Shape Factors 14/24 Demystifying Shape Factors F Square beam, mo , Mf m o 6 M (failure of beams) Shaped to φf, same material, same Mf L f ms mo 2/3 L m s 6 M * 2/3 * 2/3 * f 2/3 f 1 2/3 f 2/3 F L L f * 2/3 EXAM QUESTION: Is the cross section area constant when going from mo to ms? Shaping (material fixed) at constant bending strength reduces the mass of the component in proportion to f-2/3. Optimum approach: simultaneously maximise both M and . IFB 2012 Lecture 1 Shape Factors 15/24 Practical examples of material-shape combinations F • Materials for stiff beams of minimum weight • Fixed shape (e fixed): choose materials with greatest E • Shape e a variable: choose materials with greatest Material , Mg/m3 E, GPa e,max E 1/ 2 / / E /ρ 1/2 e, max E /ρ 1/2 e, max 1020 Steel 7.85 205 65 1.8 14.7 6061 Al 2.70 70 44 3.1 20.4 GFRP 1.75 28 39 2.9 18.9 0.9 13 8 4 11.4 Wood (oak) 1/ 2 L Same shape for all (up to e = 8): wood is best Maximum shape factor (e = e,max): Al-alloy is best Steel recovers some performance through high e,max See textbook pp. 266 and 268 for more examples. IFB 2012 Lecture 1 Shape Factors 16/24 Tute #3: p.269-270 Note that e E e E 1 / 2 1/ 2 e /e E / e 1/ 2 s new material with Silicon Carbide Alumina Boron Carbide Silicon Tungsten Carbides Steels Nickel alloys (GPa) modulus Young’s Young's Modulus (typical) (GPa) Al alloys 100 Al: e = 44 C Zinc alloys Titanium Lead alloys Concrete Plywood We call this “dragging the material’s label” PET PVC PUR PE PTFE PP 1 Rigid Polymer Foams 0.1 EVA Silicone 1/ 2 Copper alloys Mg alloys CFRP GFRP Wood 10 0.01 E Bamboo /e s /e Al: e = 1 1000 E E /e 1e-003 Cork Material substitution at constant structural stiffness allowing for differences in cross sectional Flexible Polymer Foams Polyisoprene Polyurethane shape/size to increase the structural efficiency Butyl Rubber Neoprene 1e-004 0.01 0.1 1 10 Density (typical) (Mg/m^3) 3 Density (Mg/m ) IFB 2012 Lecture 1 Shape Factors 17/24 Dragging the material labels in CES shaping at constant stiffness Unshaped Steel SF =1 1000 Drag the labels along lines of slope 1 Selection line of slope 2 Unshaped Aluminium 0 steel SF=1 Unshaped Bamboo SF= 1 100 Bamboo SF=1 Al SF =1 Young's Modulus (GPa) Shaped steel Shaped Bamboo SF=65 SF=5.6 Shaped aluminium SF = 44 10 Shaping makes Steel beams competitive with Al beams and Bamboo cane Bamboo SF =5.6 Steel SF = 65 1 Al Sf=44 1 0.1 10 Density (Mg/m^3) IFB 2012 Lecture 1 Shape Factors 18/24 Dragging the material’s label in CES shaping at constant strength Note that f * 2/3 f * 2/3 f 2 / f 2 / / * 2/3 2 f new material with 2 f *s / f * 2 / f s 2 steel f 1 2 steel f 100 2 *2 /3 Material substitution at constant structural strength allowing for differences in cross sectional shape/size to increase the structural efficiency IFB 2012 Lecture 1 Shape Factors 19/24 Dragging the material labels in CES shaping at constant strength Selection line of slope 1.5 selection line slope 1.5 steel SF =1 1000 Shaped Bamboo SF=2 (SF)2=4 Al Sf =1 Tensile Strength (MPa) Bamboo SF =1 Shaped Steel SF=7; (SF)2=49 100 bamboo SF = 2 SF^2=4 Shaped Aluminium SF=10; (SF)2=100 Shaping makes Steel beams competitive with Al beams and Bamboo cane steels SF=7 SF^2=49 10 Al 2024, SF=10 SF^2=100 0.01 0.1 1 10 Density (Mg/m^3) IFB 2012 Lecture 1 Shape Factors 20/24 Steel, Al and Bamboo scaffoldings IFB 2012 Lecture 1 Shape Factors Shaping allows you to choose. Use what is more mass-efficient, convenient, cheap, and, of course, available. 21/24 Exam questions: Shaping at constant cross section A increases the bending stiffness or strength by at constant mass. This stems from the definition of shape factor e = S/So= I/Io f = M/Mo = Z/Zo Dragging the material label in the CES charts is equivalent to shaping at constant bending stiffness or strength, so the mass is reduced by 1/e1/2 (stiffness) or by 1/f2/3 (strength). Dragging the material label along a line of slope 1 keeps the ratio E/ρ = E*/ρ* constant (* = shaped). Shaping sacrifices the stiffness in tension (tie rod) in favour of the bending stiffness (beam), thus increasing the mass efficiency of the section. IFB 2012 Lecture 1 Shape Factors 22/24 Really scary bamboo scaffoldings http://www.flickr.com/photos/photocapy/41857542/ IFB 2012 Lecture 1 Shape Factors 23/24 -Tutorial 1, Materials and Shape. Solve in this order: (4 Exercises) E9.1 (p. 623) CASE STUDY 10.2 (p.279) CASE STUDY 10.4 (p. 284) E9.8 (p. 627) Notes and Hints for E9.1 and CS10.4: E9.1 does not require the use of charts. CS 10.4: follow the procedure of case study 10.2; create a CES chart and analyse the effect of shaping on the position of the bubbles (Do that by dragging the materials’ labels.) IFB 2012 Lecture 1 Shape Factors 24/24 End of Lecture 1 IFB 2012 Lecture 1 Shape Factors IFB 2012 25/24 Shape and mode of loading Standard structural members Loading: tension/compression Area A matters, not shape Both, Area A and shape IXX, IYY matter Loading: bending Both, Area A and shape J matter Loading: torsion Both, Area A and shape Imin matter Loading: axial compression IFB 2012 Lecture 1 Shape Factors 26/24 Examples of Materials Indices including shape p. 278 Buckling: Same as elastic bending IFB 2012 Lecture 1 Shape Factors 27/24 Shape factors for twisting and buckling p. 252/253 Elastic twisting T ST K S To K 0 0 . 14 A Ko 2 T 7 . 14 K A 2 Failure under torsion fT Q Q 4 .8 Qo A 3/2 Buckling e S So E I E Io 12 I A 2 IFB 2012 Lecture 1 Shape Factors Same as elastic bending 28/24