General Introduction

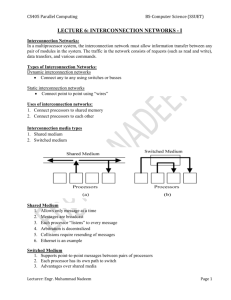

advertisement

EFFIC (Equipment for Free Form Interconnection of CIGS) Jan Wemmenhove, PM Smit Ovens Sunday 2014 event Nov. 19th, 2014 Content 1. 2. 3. 4. Brief company introduction Brief introduction into CIGS panel production Back-end interconnection process Development status Company introduction General Founded in 1936 in Nijmegen, the Netherlands. Today, our headquarters are in Eindhoven Background in display and glass Including large area glass treatment High temperature glass treatment (T>Tg) Residual stress / deformation Cost effective mass production Continuous innovation with focus on Yield improvement Cost reduction Company introduction Solar market position Leading position in thermal equipment for TF solar panel production Installed base of 110 systems in total solar market Supplied for > 4,3 GWp annual production capacity Development partner & reliable supplier to all major TFPV manufacturers Crystalline and thin film solar panel technologies Crystalline Fixed panel Composed of multiple solar-cells, made from silicon wafers (similar to microchips) Used in most PV-systems Based on Silicon (c-Si) or Gallium Arsenide (GaAs) Thin-film Fixed (glass) or flexible thin sheet Several thin layers which act as one big solar-cell Used in special applications and large plants Based on Silicon (a-Si), Cadmium Telluride (CdTe), Copper indium gallium selenide (CIGS) or Organic materials State of the art manufacturing of TFPV panels Each manufacturer has a single standard, one size only panel. Standardized manufacturing lines are optimized for lowest cost of this specific module ($/Wp). For optimal panel performance cells (± 700 mV) are formed & electrically interconnected in the manufacturing line using lasers (in case of CIGS, a mechanical scribe of P2 and P3 is very common) . This one size/fits all approach is OK for power plant / free field applications Not ideal for building integrated (BIPV) applications Disadvantages current production process. Module output loss: IC zone does not contribute to module output. Production yield loss: material removal is source of contamination for the subsequent TF deposition processes. Limited module customization. EFFIC solution Alternative approach structuring/interconnection Instead of doing the interconnections as integral steps in the line it is also possible to take a font end / back end approach Front end would be the monolithic deposition of all funtional layers Back end would be shaping, cell structuring, interconnection & lamination Advantages back-end interconnection process Higher conversion efficiency of TF PV modules due to lower output losses in cell interconnection. Lower CoO for module manufacturing , because back-end interconnection reduces defect formation and increases the production yield. More flexibility of the interconnection layout at the end of the production process of PV modules. Different interconnection technology required Besides material removal by lasers it is also required to add materials: isolators & conductors To maintain flexibility and large area precision Inktjet printing is the preferred deposition method Process development ongoing. Produzo tool Main advantage of a front/back-end approach Flexibility in size & shape is possible Relatively large front end substrates (e.g. 1200 x 1200 mm) Store these coated mother plates in N2 conditions Mechanical sizing of these plates to a specific demand Fast response to a market request, e.g. delivery < 7 days on site Full shape freedom including triangles, rounded, circles, etc Nesting programs to optimize material usage & cost Cell structuring & interconnection scheme optimized by software for each different module Except for flexible cell structuring & interconnection no new technologies required to implement this approach Customer analysis Potential customers/segments Potential customers: TF PV manufacturers (CIGS as well as Si, CdTe and on the longer term OPV). PV development labs. Suppliers of functionalized steel and glass, building and construction materials (through their suppliers). Potential future development: foundries taking producing customer/project specific modules based on standard cell materials. Segments: BIPV (Building Integrated PV): PV systems incorporated in building elements. BAPV (Building Added PV): PV systems added to existing buildings. Supporting local PV panel manufacturing The market approach is different and supports a local for local approach Much more comparable to e.g. double glazing Good possibility to allow for EU manufacturing on highly automated production lines State of development of the product at the end of the project Start of project: TRL3: concept of back-end interconnecting labscale TF Si and CIGS cells has been proven. Lab scale validation is still needed (TRL4). End of project: TRL6: Product demonstrated with extensive testing on relevant PV modules of industrial CIGGS manufacturer Nexcis (60x30 cm). At project closure, the design will have been upscaled to cover full market potential (60x120 cm). Thank You SMIT Ovens BV Ekkersrijt 4302 5692 DH SON The Netherlands Visit us at www.smitovens.com