Chap. 8 Technical Note: Statistical Process Control

advertisement

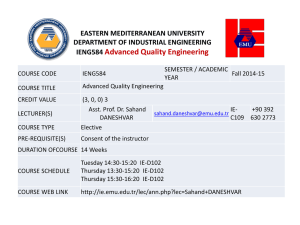

Statistical Quality Control (SQC) - Why control the process? • Products and services require uniform quality. • Process variation is inevitable • reduce variation for better quality (conformance to specs) GSBA 534 Some Generic Tools for QC - Process flow chart - Pareto analysis - Run chart - Histogram - Checksheet - Causes and effect diagram (Fishbone diagram) - Control charts GSBA 534 SQC - Sources of variation in process: • random variations (can not be controlled) • - non-random variations (can be controlled) What should we do? • We can not eliminate the variation, but we can identify the sources of non-random variations and hence improve the process. GSBA 534 Statistical Sampling - Identify the problems • 100% inspection • sampling º DO NOT TEMPER WITH THE SYSTEM!!! - Sample measurement: • variable (continuous): such as weight, length, …. • Attribute (good, no-good) º defectives: the acceptability of products across a range of characteristics º defects: a product that has at least one defective GSBA 534 Control Charts - Purpose: • Using the samples collected from the process, and calculating the required statistics to construct a time sequence chart to detect the process variation. - Process control with variable measurements: • For each sample, we measure the weight, volume, length, or other variable measurements. • Process control charts (variable measures): º X-bar chart º R chart GSBA 534 Control Charts (variable measures) - The sample mean follows a normal distribution. • If the process does not change over time, every sample mean should follow the same normal distribution. - X-bar chart: • A plot of the sample means taken from the process. It is used to detect the change of the process mean (mean for the normal distribution). - R chart: • A plot of the sample variation range. It is used to detect the change of process variation (variance for the normal distribution). GSBA 534 X-bar and R charts - Change of process mean - Change of variance GSBA 534 Developing Control Charts 1. For each sample, - calculate the sample mean. Xi X 1 X 2 X 3 ... X n n (n is the number of observations in a sample (sample size)) - calculate the range. 2. For all the samples, - calculate the overall mean. - calculate the average range. Ri (max. in sample i) - (min. in sample i) X X 1 X 2 X 3 ... X k k R R1 R2 R3 ... Rk k (k is the number of samples) GSBA 534 Developing Control Charts (continued) 3. For the X-bar chart: - Upper control limit (UCL)= X A2 R - center line = X - Lower control limit (LCL)= X A2 R 4 For the R chart: - Upper control limit (UCL)= D4 R - center line = R - Lower control limit (LCL)= D3 R 5. Look for A2, D3, D4 in Exh. S5.4. GSBA 534 Control Charts-Example The following measures of shaft diameters were taken from a company producing transmission boxes. Construct the X-bar and R charts. sample 1 2 3 4 GSBA 534 diameter (in inches) 2.10 1.99 2.00 2.09 2.08 1.98 2.01 2.10 1.97 2.05 1.98 2.05 Example (continued) - X-bar chart - R chart GSBA 534 Example (continued) Two new measures were taken this week. Using the control charts developed, explain your findings. sample 1 2 GSBA 534 diameter (in inches) 2.31 1.86 1.86 1.85 1.91 1.79 Interpreting the Control Charts - X-bar and R charts MUST BE USED TOGETHER!! sample measurements 1 10.0 10.1 10.2 2 13.0 9.5 7.8 - sample 1 and 2 have the same mean (10.1) - sample 2 has greater variation than sample 1. (R1=0.2, R2=5.2) sample measurements 1 10.0 10.1 10.2 2 13.0 13.1 13.2 - sample 1 and 2 have the same variation (0.2) - sample 2 has a higher mean than sample 1. - See Exh. S5.3. GSBA 534 Control Chart for attribute measures: p chart - Sample units are only classified into one of two categories (good or bad, success or failure, etc.) total # of defects from all samples p (# of samples) X (sample size) Sp p (1- p ) n UCL p zS p LCL p zS p GSBA 534 P Chart-Example A visual inspection for scratches produced the following data for last week. For each sample, 30 units were inspected. Sample 1 2 3 4 5 GSBA 534 # of defects 5 4 4 5 7 sample 6 7 8 9 10 # of defects 4 5 6 4 5 Example (continued) This week 30 units were inspected on each of 2 occasions. On Monday, 6 units were found defective. On Tuesday, 9 were found defective. Is this process in or out of control? GSBA 534 Process Capability - Control charts are of little value if the process is not capable of making products within design specification (or tolerance) limits. - Process capability = 6 s (s: standard deviation of the process) - Process capability ratio = Upper tolerance limit (UTL) - Lower tolerance limit (LTL) 6s - higher ratio: the process is potentially more capable of making the product within the design specification. GSBA 534 Process Capacity vs. Design Specs (Tolerance) - process variability matches specs - process variability well within specs - process variability exceeds specs GSBA 534 Capability Index (Cpk) - Indicates how well the process performs relative to the target value. - Cpk is used to determine whether the process mean is closer to the UTL or LTL. X LTL UTL X Cpk min , 3s 3s GSBA 534 Process Capability-Example A metal fabricator produces connecting rods with an outer diameter that has a specification of 1.000 +/- 0.010 inch. The process mean is determined to be 1.002 inches with a standard deviation of 0.003 inches. What do you think about the process? GSBA 534 Taguchi’s Cost Function GSBA 534