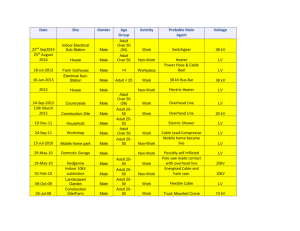

ABWL-EK Kapitel 4

advertisement

Chapter 4 Planning the Production Program Chapter 4/1 Planning the Production Program • Based on demand forecasts and orders plan the production quantities for the (main) products for the „next“ periods • 2 variants: • Aggregate Planning (aggregated view, tactical planning, medium run) few product groups for the next (months), quarters, or years capacities can be adjusted (hiring/firing, overtime, holidays, subcontracting ...) • Master Production Scheduling (more detailed view, operational planning, short run) all main end products for next few shifts, days, or weeks (or months) capacities more or less fixed (except for overtime) • Typically solved as an LP model Chapter 4/2 Aggregate Planning 2 extreme scenarios in case of seasonal demand: • Always produce the demand (forecast) „Synchronisation“ (zero inventory plan) cost of hiring/firing, overtime, subcontracting, idle time, … • Always produce average yearly demand (high utilization) „Emancipation“ (level workforce plan) inventory holding cost Goal: • Trade-off between these costs minimize total costs • Solution by column minimum procedure Chapter 4/3 Synchronisation Synchronisation: No active planning, just reaction on demand (forecasts) Always produce the demand (forecast) overview Chapter 4/4 Emancipation Emancipation: More or less constant demand, constant (high) resource utilization, fluctuating demand is fulfilled by building up and depleting inventory. Constant Production Build up Reduce Inventory Inventory overview Chapter 4/5 Column Minimum Procedure • In each period regular capacity can be extended at extra cost (overtime, subcontracting, …) Cope with fluctuating demand (capacity shortages): • • Produce more than demand – build up inventory, OR Use extra capacity Solution a special case (just one product group) as a TP In each cell (row t … production period, half row k … capacity type, and column … demand period) the unit extra cost are: ctk = uk + h( - t) where: uk ... Extra cost (per unit) of production using extra capacity k (e.g. overtime) h ... Inventory holding cost per unit and per period, h( - t) ... Inventory holding per unit if produced - t periods early Solve as transportation problem using Column Minimum Procedure table Chapter 4/6 Example I Given • 6 Periods • Normal capacity in each Period: 100 units • Just 1 type of extra capacity: k = 1 max. possible extra capacity: 10 units • Cost: – Holding cost: h = 1 € per unit and period – Cost of extra capacity: u1 = 1,5 € for each unit produced in overtime k = 1 Determine optimal production plan Chapter 4/7 Example I - Table for period Period Normal 1 Extra Normal 2 Extra production in period 1 2 3 4 5 6 capacity 0,0 1,0 2,0 3,0 4,0 5,0 100 1,5 2,5 3,5 4,5 5,5 6,5 10 0,0 1,0 2,0 3,0 4,0 100 1,5 2,5 3,5 4,5 5,5 10 0,0 1,0 2,0 3,0 100 1,5 2,5 3,5 4,5 10 0,0 1,0 2,0 100 1,5 2,5 3,5 10 0,0 1,0 100 1,5 2,5 10 0,0 100 1,5 10 Normal 3 Extra Normal 4 Extra Normal 5 Extra Normal 6 Extra Demand 90 110 50 110 100 130 No extra cost Advance production: holding cost h*(# periods) h=1 Extra capacity extra cost u in 2nd half row u = 1,5 formula No shortages permitted (otherwise shortage cost) Chapter 4/8 Example I – Column Minimum Procedure Prod 90 10 10 Prod 100 100 0 Column Minimum Procedure 100 100 100 0 50 10 10 30 50 40 70 70 0 100 100 100 0 100 100 total cost 10 10 110 10 10 100 100 10 10 110 30 20 10 Chapter 4/9 Example I – Cost & Production Plan Total cost table = 590 * C + 10 * 1 + 10 * 1 + 10 * 3 + 10 * 2,5 + 10 * 1,5 Production cost Cost of production using extra capacity Holding cost = 590 * C + 90 GE Production plan 1. Per. 2. Per. 3. Per. 4. Per. 5. Per. 6. Per. Normal 100 100 70 100 100 100 Extra 0 0 0 0 10 10 Chapter 4/10 Example II 2 sources of extra capacity • k = 1 overtime & • k = 2 subcontracing table Chapter 4/11 Example II – Variant 1 • Each row now has 3 sub-rows for 3 sources of capayity (normal, overtime, subcontracting) • Make it completely equivalent to TP by adding Dummy Column for unused capacity • Total capacity = 2780 Total demand = 2550 unused capacity = 2780 - 2550 = 230 • Initial inventory can be treated in 2 ways: Variant 1: treat as additional (artificial) production row 0 oder Variant 2: subtract from demand of first period data Chapter 4/12 Example II – Variant 2 • Each row now has 3 sub-rows for 3 sources of capayity (normal, overtime, subcontracting) • Make it completely equivalent to TP by adding Dummy Column for unused capacity • Total capacity = 2780 Total demand = 2550 unused capacity = 2780 - 2550 = 230 • Initial inventory can be treated in 2 ways: Variant 1: treat as additional (artificial) production row 0 oder Variant 2: subtract from demand of first period 700 data Chapter 4/13 Example II – Solution • Column minimum procedure 50 150 100 • Total cost = 100*0 +(700+700+700)*40 +(50+50)*50 +50*52 +150*70 +50*72 = 105700 Chapter 4/14