Capacity and Aggregate Planning

advertisement

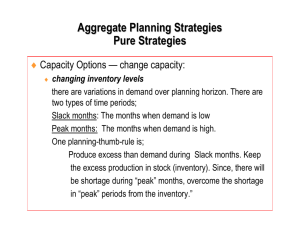

IES 371 Engineering Management Chapter 14: Aggregate Planning Week 13 August 31, 2005 Learning Objectives: Understand the concepts and methods of aggregate planning Formulate and solve capacity planning problem 1 Aggregate Plan Aggregate Plan: A statement of a company’s production rates, workforce levels, and inventory holding based on estimates of customer requirements and capacity limitations Service Industry Staffing Plan Regarding staffs and labor related factors Manufacturing Industry Production Plan Regarding production rates and inventory 2 Aggregate Production Planning (APP) Determines resource capacity to meet demand For intermediate time horizon, 6-12 months Not feasible to build new facility May be feasible to hire/lay off workers, overtime, or subcontract Adjusting capacity OR managing demand 3 How should an aggregate plan fit with other plans? Business or annual plan Production or staffing Plan (Aggregate Plan) MPS or workforce schedule Figure 14.1 4 Aggregate Plan – Managerial Inputs Distribution and marketing Customer needs Demand forecasts Competition behavior Operations Current machine capacities Plans for future capacities Workforce capacities Current staffing level Materials Supplier capabilities Storage capacity Materials availability Aggregate plan Engineering New products Product design changes Machine standards Accounting and finance Cost data Financial condition of firm Human resources Labor-market conditions Training capacity 5 Aggregate Plan – Outputs Aggressive Alternatives Complementary Products Competitive Pricing Reactive Alternatives Size of Workforce and Workforce Adjustment Inventory Levels Aggregate plan Production per month (in units or $) Units or dollars Of Backlogs, backorders , or stockout Units or dollars subcontracted 6 Aggregate Planning Objectives Minimize Costs/Maximize Profits Maximize Customer Service Minimize Inventory Investment Minimize Changes in Production Rates Minimize Changes in Workforce Levels Maximize Utilization of Plant and Equipment 7 Demand Units Examples of Capacity Adjustment to Meet Demand Time 1. Producing at a constant rate and using inventory to absorb fluctuations in demand 2. Hiring and firing workers to match demand 3. Maintaining resources for high demand levels 4. Increase or decrease working hours (overtime and undertime) Subcontracting work to other firms Using part-time workers Providing the service or product at a later time period (backordering) 5. 6. 7. 8 Planning Strategies Chase Strategies PURE STRATEGIES Level Strategies Match demand during the planning horizon by either Vary workforce or vary output rate Maintain a constant workforce level or constant output rate during the planning horizon Constant workforce or constant output rate Mixed Strategies Combined several strategies 9 Pure Strategy Level Production Chase Demand Demand Demand Production Units Units Production Time Time What are pros / cons of these strategies? 10 TABLE 14.1 PLANNING STRATEGIES FOR AGGREGATE PLANS Possible Alternatives during Slack Season Possible Alternatives during Peak Season 1. Chase #1: vary workforce level to match demand Layoffs Hiring 2. Chase #2: vary output rate to match demand Layoffs, undertime, vacations Hiring, overtime, subcontracting 3. Level #1: constant workforce level No layoffs, building anticipation inventory, undertime, vacations No hiring, depleting anticipation inventory, overtime, subcontracting, backorders, stockouts 4. Level #2: constant output rate Layoffs, building anticipation inventory, undertime, vacations Hiring, depleting anticipation inventory, overtime, subcontracting, backorders, stockouts Strategy 11 Aggregate Planning Costs Regular-Time Costs Overtime Costs Hiring and Layoff Costs Inventory Holding Costs Backorder and Stockout Costs 12 Ex 1 Candy Company Given the following costs and quarterly sales forecasts of a candy company, compare the two strategies: Strategy 1: Level production with constant workforce level Strategy 2: Chase production by varying workforce level Quarter Spring Summer Fall Winter Sale Forecast (LB) 80,000 50,000 120,000 150,000 Hiring cost Firing cost Inventory carrying cost Production rate per employee Beginning workforce $100 per worker $500 per worker $0.50 per pound per quarter 1000 pounds per quarter 100 workers 13 A method of LP Gather all cost info into one matrix Try to obtain the lowest cost alternative Quarter Transportation Method Alternatives Quarter 1 2 Beginning inventory 0 Regular time r Regular time Overtime Subcontract Regular time 3 Overtime Subcontract Regular time 3h 4h r+h r+2h r+3h u R1 c+h c+2h c+3h 0 O1 s s+h s+2h s+3h 0 S1 r+b r r+h r+2h u R2 c+b c c+h c+2h 0 O2 s+b s s+h s+2h 0 S2 r+2b r+b r r+h u R3 c+2b c+b c c+h 0 O3 s+2b s+b s s+h 0 S3 r+3b r+2b r+b r u R4 c+3b 4 2h Overtime Subcontract 2 4 I0 c 1 h 3 Unused Total Capacity Capacity c+2b c+b c 0 Overtime O4 s+3b s+2b s+b s 0 Subcontract S4 14 Requirements D1 D2 D3 D4 + I4 U Notations It = inventory at the end of period t (I0 = beginning inventory) h = holding cost per unit per period, r = regular production cost per unit, o = overtime cost per unit, u = undertime cost per unit s = subcontracting cost per unit, b = backordering cost per unit per period Rt = regular-time capacity in period t Ot = overtime capacity in period t St = subcontracting capacity in period t Dt = forecasted demand for period t U = total unused capacities 15 Tableau Method Step 1: Put all capacities from the total capacity column into the unused capacity column. Next, put unit costs in each of the small boxes Step 2: In column 1 (period 1), allocate as much production as you can to the cell with the lowest cost but do not exceed the unused capacity in that row or the demand in that column. Step 3: Subtract your allocation from the unused capacity for the row. This quantity must never be negative. 16 Tableau Method (Cont’d) Step 4: If there is still some demand left, repeat step 2, allocating as much production as possible to the cell with the next-to-lowest cost. Repeat until the demand is satisfied. Step 5: Repeat steps 2 through 4 for periods 2 and beyond. Take each column separately before proceeding to the next. Be sure to check all cells with unused capacity for the cell with the lowest cost in a column. 17 Ex 2: Transportation Method Given the following costs and quarterly sales forecasts, use the transportation method to design a production plan. What is the total cost of the plan? Quarter Sale Forecast (unit) 1 2 3 4 50,000 150,000 200,000 52,000 Inventory carrying cost = $3 per unit per quarter Production/worker = 1000 units/quarter Regular workforce = 50 workers Overtime capacity = 50,000 units Subcontracting capacity = 40,000 units Regular production cost = $50/unit Overtime production cost = $75/unit Subcontracting cost = $85/unit 18 Linear Programming Model (LP) Pure/Mixed Strategy: not guarantee optimal solution LP: can get optimal solution LP: Excel, LINGO, CPLEX, … LP Formulation** Objective function Constraints Ex 2: Formulate LP model for Ex 1 Candy Company and Ex 2 19