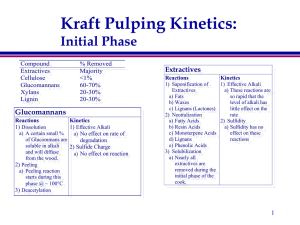

Delignification Kinetics Models H Factor Model

advertisement

Empirical Kraft Pulping Models • Models developed by regression of pulping study results • Excellent for digester operators to have for quick reference on relation between kappa and operating conditions • “Hatton” models are excellent examples of these Kappa or Yield 15% EA 18% EA 20% EA H-factor 1 Emperical Kraft Pulping Models Hatton Equation Kappa (or yield) = -(log(H)*EAn) ,, and n are parameters that must be fit to the data. Values of ,, and n for kappa prediction are shown in the table below. n Hemlock 259.3 22.57 0.41 21-49 Jack Pine 279.3 30.18 0.35 22-53 Aspen 124.7 5.03 0.76 14-31 Species kappa range Warning: These are empirical equations and apply only over the specified kappa range. Extrapolation out of this range is dangerous! 2 Delignification Kinetics Models H Factor Model • Uses only bulk delignification kinetics dL / dt ke32,000 / RT k = Function of [HS-] and [OH-] R= 1.987 cal mole * K T [=] °K 3 Delignification Kinetics Models H Factor Model t H k0 e 0 32, 000/ RT ( t ) dt Relative reaction rate k0 is such that H(1 hr, 373°K) = 1 4 Delignification Kinetics Models H Factor Model • Provides mills with the ability to handle common disturbance such as inconsistent digester heating and cooking time variation. 5 170 900 700 130 500 300 H factor equal to area under this curve 90 100 Temperature °C Relative Reaction Rate Delignification Kinetics Models H Factor/Temperature 1 2 Hours from Start 6 Kraft Pulping Kinetics H Factor/Temperature Lignin (% of Pulp) 30 25 150°C 160°C 170°C 20 15 10 5 0 0 500 1000 1500 2000 2500 H Factor 7 Delignification Kinetics Models Kerr model ~ 1970 dL / dt k * e 32, 000 / RT [OH ] * L • H factor to handle temperature • 1st order in [OH-] • Bulk delignification kinetics w/out [HS-] dependence 8 Delignification Kinetics Models Kerr model ~ 1970 Integrated form: Lf Li t dL K e 0 L * f ( L) 32, 000 RT ( t ) H-Factor Functional relationship between L and [OH-] 9 Delignification Kinetics Models Kerr model ~ 1970 Slopes of lines are not a function of EA charge 10 Delignification Kinetics Models Kerr model ~ 1970 Model can handle effect of main disturbances on pulping kinetics • Variations in temperature profile » Steam demand » Digester scheduling » Reaction exotherms • Variations in alkali concentration » White liquor variability » Differential consumption of alkali in initial delignification - Often caused by use of older, degraded chips • Good kinetic model for control 11 Delignification Kinetics Models Gustafson model • Divide lignin into 3 phases, each with their own kinetics » 1 lignin, 3 kinetics • Transition from one kinetics to another at a given lignin content that is set by the user. For softwood: Initial to bulk ~ 22.5% on wood Bulk to residual ~ 2.2% on wood 12 Delignification Kinetics Models Gustafson model • Initial » dL/dt = k1L » E ≈ 9,500 cal/mole • Bulk » dL/dt = (k2[OH-] + k3[OH-]0.5[HS-]0.4)L » E ≈ 30,000 cal/mole • Residual » dL/dt = k4[OH-]0.7L » E ≈ 21,000 cal/mole 13 Delignification Kinetics Models Gustafson model Another model was formulated that was of the type dL/dt = K(L-Lf) Where Lf = floor lignin level – set @ 0.5% on wood • Did not result in any better prediction of pulping behavior 14 Delignification Kinetics Models Purdue Model 2 types of lignin: • High reactivity • Low reactivity Assumed to react simultaneously 1/ 2 dL / dt (k1[OH ] 1/ 2 k2 [ HS ] )( L L f ) Lf assumed to be zero High reactivity E ≈ 7000 cal/mole Ek1 ≈ 8300 cal/mole Low reactivity Ek2 ≈ 28,000 cal/mole 15 Delignification Kinetics Models Purdue Model Potential difficulties • High reactivity lignin (initial lignin) dependent on [OH-] and [HS-] • No residual lignin kinetics 16 Delignification Kinetics Models Andersson, 2003 • 3 types of lignin: » Fast » Medium » slow Lignin [%ow] 10 Assumed to react simultaneously, like Purdue model 1 total lignin 10 0 L3 lignin L1 lignin 10 L2 lignin -1 0 50 100 150 200 time [min] 250 300 17 Delignification Kinetics Models Andersson, 2003 Fast ≈ 9% on wood (all t) dL/dt = k1+[HS-]0.06L E ≈ 12,000 cal/mole Medium ≈ 15% on wood (t=0) dL/dt = k2[OH-]0.48[HS-]0.39L E ≈ 31,000 cal/mole Slow ≈ 1.5% on wood (t=0) dL/dt = k3[OH-]0.2L E ≈ 31,000 cal/mole 18 Delignification Kinetics Models Andersson, 2003 Model also assumes that medium can become slow lignin depending on the pulping conditions L*≡ Lignin content where amount of medium lignin equals the amount of slow lignin Complex formula to estimate L*: L* 0.49([OH ] 0.01) 0.65 ([ HS ] 0.01) 0.19 * (1.83 2.97 *10 (T 273.15) ) 5 2 19 Delignification Kinetics Models Andersson, 2003 Total lignin L2,L3 Lignin [%ow] 101 L* Increasing [OH-] 100 10-1 0 50 100 150 time [min] 200 250 300 350 20 Model Performance Gustafson model 50 40 1.5 mm chips Screened 30 Kappa 20 10 0 15 20 25 30 % Active Alkali on wood Pulping data for thin chips – Gullichsen’s data 21 Model Performance Gustafson model 60 50 Mill chips 40 Total 30 Kappa 20 10 0 15 20 25 30 % Alkali charge Pulping data for mill chips - Gullichsen’s data 22 Model Performance Gustafson model 80 60 Predicted 40 Kappa 20 0 0 20 40 60 80 Measured Kappa Virkola data on mill chips 23 Model Performance (Andersson) Purdue Model Purdue model suffers from lack of residual delignification 24 Model Performance (Andersson) Purdue Model Purdue model suffers from lack of residual delignification 25 Model Performance (Andersson) Gustafson Model Model works well until very low lignin content 26 Model Performance (Andersson) Gustafson Model Model handles one transition well and the other poorly 27 Model Performance (Andersson) Andersson Model Andersson predicts his own data well 28 Model Performance (Andersson) Andersson Model Model handles transition well 29