X - ORT Braude College

advertisement

POLITECNICO DI TORINO - ITALY

DIGEP – Department of Management and Production Engineering

7TH GALILEE QUALITY CONFERENCE, “QUALITY – THEORY AND PRACTICE”

ORT BRAUDE COLLEGE OF ENGINEERING IN KARMIEL

MAY 1ST 2014

Fiorenzo Franceschini

Maurizio Galetto

“QFD is a method to transform user demands into

design quality, to deploy the functions forming

quality, and to deploy methods for achieving the

design quality into subsystems and component

parts, and ultimately to specific elements of the

manufacturing process”.

Akao (1988)

2

I like …

I like …

I want …

I wa I want …

I like .

I want …

I want …

I want …

I like …

NEW PRODUCT

CUSTOMERS

COMPANY

3

QFD PLANNING STRUCTURE

Phase IV

Phase III

Phase II

Phase I

PROCESS PLANNING

MATRIX

PART / SUBSYSTEM

DEPLOYMENT MATRIX

PRODUCT

PLANNING MATRIX

Customer

Customer

Requirements

requirements

PROCESS / QUALITY

CONTROL MATRIX

Critical

Engineering

Product

Characteristics

Requirement

Critical

Components

Characteristics

Critical

Process

Step

Process &

Quality Control

Parameters

Critical

Process

Steps

Critical

Components

Characteristics

Critical

Engineering

Product

Characteristics

Requirement

4

2. Prioritization of Customer

Requirements

1. Customer Requirements

6. Relationship Matrix

4. Competitive Prioritization of

Customer Requirements

3. Competitive Benchmarking

7. Correlation

Matrix

5. Engineering Characteristics

8. Prioritization of Engineering

Characteristics

5

•

•

•

•

•

Easy to hold

Does not smear

Point lasts

Does not roll

…

6

Customer

Requirements

Engineering

Characteristics

f

QFD

work

group

L

•

•

•

•

hexagonality,

erasure residue,

dust,

…

7

Customer Requirements

(CRs)

Easy to hold

Does not smear

Point lasts

Does not roll

Engineering Characteristics

(ECs)

•

•

•

•

•

•

•

•

•

•

•

length

hexagonality

time between sharpening

lead dust generated

erasure residue

length

time between sharpening

lead dust generated

erasure residue

length

hexagonality

8

Does not smear

Point lasts

Does not roll

Erasure residue

Hexagonality

O

Lead dust

generated

Easy to hold

Time between

sharpening

Customer Requirements

(WHATS)

Length

Engineering Characteristics

(HOWS)

X

O

X

X

O

X

X

X

-> weak relationship

O -> medium relationship

X -> strong relationship

9

• CRs prioritization (are all CRs equally

important?)

• ECs prioritization.

10

Easy to hold

3rd

Does not smear

2nd

Point lasts

1st

Does not roll

3rd

O

Erasure residue

Hexagonality

Lead dust

generated

Time between

sharpening

Length

Customer Requirements

(WHATS)

Priorities of

WHATS

Engineering Characteristics

(HOWS)

X

O

X

X

O

X

X

X

Priorities of HOWS

Can CRs prioritization influence

ECs prioritization?

11

Steps:

1. assign a numerical importance to each CR;

2. convert the relationships symbols between

CRs and ECs into “equivalent” numeric

values;

3. determine the numerical importance of

each EC using the ISM algorithm.

12

Does not smear

3

Point lasts

5

Does not roll

2

1

2

3

4

5

->

->

->

->

->

not important at all

minor importance

some importance

strong importance

very strong importance

Erasure residue

O

Hexagonality

2

Lead dust

generated

Length

Easy to hold

Customer Requirements

(WHATS)

Time between

sharpening

Importance of

WHATS

Engineering Characteristics

(HOWS)

X

O

X

X

O

X

X

X

13

Importance of

WHATS

Length

Time between

sharpening

Lead dust

generated

Hexagonality

Erasure residue

Engineering Characteristics

(HOWS)

Easy to hold

2

3

0

0

9

0

Does not smear

3

0

3

9

0

9

Point lasts

5

1

3

9

0

9

Does not roll

2

1

0

0

9

0

Customer Requirements

(WHATS)

empty box -> 0

-> 1

O -> 3

X -> 9

14

Importance of

WHATS

Length

Time between

sharpening

Lead dust

generated

Hexagonality

Erasure residue

Engineering Characteristics

(HOWS)

Easy to hold

2

3

0

0

9

0

Does not smear

3

0

3

9

0

9

Point lasts

5

1

3

9

0

9

Does not roll

2

1

0

0

9

0

13

24

72

36

72

Customer Requirements

(WHATS)

Priorities of HOWS

w1 2 3 3 0 5 1 2 1 13

w2 2 0 3 3 5 3 2 0 24

w2 ...

n

w j di ri , j

i 1

15

•

•

•

•

•

•

Intuitional.

Easy to use.

Easy to interpret.

Use of standard Mathematical operators.

Largely diffused.

…

16

• Are customers really able to express

CRs importance on ratio scales

(cardinal properties)?

• What is the correct symbol

codification in the relationship matrix

(1-2-3, 1-3-5, 1-3-9, …)?

• How to select the right scale for

importance and symbol codification?

• Is there any arbitrariness in scale

definition (zero point, graduation,

unit, …)?

17

All CRs have the same importance d = 1.

EC1

EC2

EC1

EC2

CR1

X

X

CR1

X

X

CR2

X

CR2

X

CR3

O

X

CR3

O

X

CR4

O

CR4

O

CR5

O

CR5

O

CR6

O

CR6

O

Importance

18

Importance

22

15

Codification 1-3-5

Codification 1-3-9

EC1 > EC2

EC1 < EC2

27

18

• The response scale has ordinal properties:

Scale level

1

2

Description

Not important at all

Minor importance

3

4

5

Some importance

Strong importance

Very strong importance

• Arbitrary promotion of results from ordinal

to interval or ratio scales.

19

3

1

2

3

4

5

2

1

2

3 4

5

5

1 23

4

5

Can we sentence that the mean value of the

3 2 5 10

sample is x

?

3

3

20

CRs

CR1

CR2

1

2

X

3

4

5

X

CR3

X

We can sentence:

• CR1 is better than CR2

We cannot sentence:

• CR1 is evaluated twice CR2 (ratio scale)

• the distance between CR3 and CR1 is 3 scale

units (interval scale).

21

• Respondents’ orderings:

1) CR3 > CR1 > CR2

2) CR1 > CR2 > CR3

3) ...

• How operate a fusion of respondents’

orderings?

22

2. Prioritization of Customer

Requirements

1. Customer Requirements

6. Relationship Matrix

4. Competitive Prioritization of

Customer Requirements

3. Competitive Benchmarking

7. Correlation

Matrix

5. Engineering Characteristics

8. Prioritization of Engineering

Characteristics

23

• In the scientific literature there are many

approaches for prioritizing CRs.

• Some of them may lead to misleading results.

• In some cases we assist to a

violation of scale properties

on which CRs are evaluated.

24

• The AHP is a technique of Multiple Criteria

Decision Making developed by Thomas L.

Saaty (1980).

• It is based on the paired comparison of CRs.

• The result is a global ordering of the CRs.

25

PAIRED COMPARISON MATRIX

a12

1

1/ a

1

12

A

...

...

1/ a1n 1/ a2n

... a1n

... a2n

... ...

... 1

d1 / d1

d / d

2 1

dn / d1

d1 / d2

d2 / d2

dn / d2

d1 / dn

d2 / dn

dn / dn

A d max d

d1

d

dn

PRIORITY

VECTOR

26

CR1 (Easy to hold)

CR2 (Does not smear)

CR3 (Point lasts)

CR4 (Does not roll)

CRs Importance

1

5

6

7

0.61

CR2 (Does not smear)

1/5

1

4

6

0.24

CR3 (Point lasts)

1/6

1/4

1

4

0.10

CR4 (Does not roll)

1/7

1/6

1/4

1

0.05

CR1 (Easy to hold)

27

• Not always the consistency of paired

comparisons is guaranteed.

• Respondents usually do not have a common

reference scale.

• It is based on the assumption that Saaty’s

scale for paired comparison has ratio scale

properties.

• It is “effective” only with small numbers of

CRs.

28

• It may lead to inconsistencies in judgment.

Example:

If CR1 > CR2 and CR2 > CR3 , it can happen for

some individuals that CR3 > CR1 .

29

2. Prioritization of Customer

Requirements

1. Customer Requirements

6. Relationship Matrix

4. Competitive Prioritization of

Customer Requirements

3. Competitive Benchmarking

7. Correlation

Matrix

5. Engineering Characteristics

8. Prioritization of Engineering

Characteristics

30

The scientific literature proposes many

techniques which differ for:

• typology of data,

• properties of data and scales,

• mathematical models for

synthesis/aggregation of the information

collected from the customers (mean,

median, standard deviation, …),

• models linking CRs and ECs in the

relationship matrix (linear, weighted, …).

31

• Independent Scoring Method (ISM) [Akao, 1988],

• Multiple Criteria Decision Aid (MCDA) methods

(Electre II, …) [Roy, 1991].

• Interactive Design Requirement Ranking (IDRR)

algorithm [Franceschini, 2002].

• Paired Comparison Method (PC) [Thurstone,

1927].

• Ordinal Prioritization Method (OPM)

[Franceschini, 2014].

• ...

32

Independent

Scoring Method

(ISM)

Ordinal

Prioritization

Method (OPM)

Multiple Criteria

Decision Aid

(MCDA)

Interactive Design

Requirement

Ranking (IDRR)

Paired

Comparison

Method (PC)

33

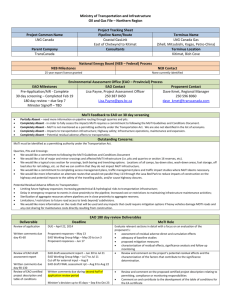

Coefficients of Relationship matrix

CRs importance

cardinal scale

ordinal scale

cardinal

scale

Independent

Scoring Method

(ISM)

Thurstone scaling

+

Independent

Scoring Method

(ISM)

ordinal

scale

Thurstone scaling

Multiple Criteria

+

Decision Aid

Multiple Criteria

(MCDA) methods

Decision Aid

(MCDA) methods

ordering

Ordered

Weighted

Averaging (OWA)

ordering

Ordinal

Prioritization

Method (OPM)

34

• It is a variant of Yager’s algorithm (2001).

• Each EC is evaluated according to any CR, a

preference vector corresponding to each

CR can be defined.

• There are 3 fundamental phases:

1. Construction and reorganization of

decision-makers’ preference vectors.

2. Definition of the reading sequence.

3. Generation of the fused ordering.

35

Reorganized vectors for the pencil example (CR3 > CR2 > CR1 CR4)

CR3

CR2

CR1CR4

{EC3,EC5}

{EC2}

{EC1}

{EC3,EC5}

{EC2}

Null

{EC4,EC4}

{EC1}

{EC1}

{EC4}

{EC1,EC4}

{EC2,EC2,EC3,EC3,EC5,EC5}

36

The ordering algorithm

Pass

Element (I)

Cumulative Occurrences (Ok)

Residual elements (R)

Gradual Ordering

EC1

EC2

EC3

EC4

EC5

(Tk = 1)

(Tk = 1)

0

-

0

0

0

0

0

{EC1, EC2, EC3, EC4, EC5}

-

1

{EC3,EC5}

0

0

1

0

1

{EC1, EC2, EC4}

EC3 EC5

2

{EC3,EC5}

0

0

2

0

2

{EC1, EC2, EC4}

EC3 EC5

3

{EC4,EC4}

0

0

2

2

2

{EC1, EC2}

EC3 EC5 > EC4

4

{EC2}

0

1

2

2

2

{EC1}

EC3 EC5 > EC4 > EC2

5

{EC2}

0

2

2

2

2

{EC1}

EC3 EC5 > EC4 > EC2

6

{EC1}

1

2

2

2

2

-

EC3 EC5 > EC4 > EC2> EC1

7

{EC1}

2

2

2

2

2

-

EC3 EC5 > EC4 > EC2> EC1

8

Null

2

2

2

2

2

-

EC3 EC5 > EC4 > EC2> EC1

9

{EC1}

3

2

2

2

2

-

EC3 EC5 > EC4 > EC2> EC1

10

{EC4}

3

2

2

3

2

-

EC3 EC5 > EC4 > EC2> EC1

11

{EC1,EC4}

4

2

2

4

2

-

EC3 EC5 > EC4 > EC2> EC1

12

{EC2,EC2,EC3,EC3,EC5,EC5}

4

4

4

4

4

-

EC3 EC5 > EC4 > EC2> EC1

FINAL ORDERING

37

• Ordered Weighted Average (OWA)

emulator of arithmetic mean was first

introduced by Yager (1993).

• This operator is typically used with

ordinal scales.

SAMPLE SIZE

LINGUISTIC QUANTIFIER

ORDERED ELEMENT

OF THE SAMPLE

OWA Max MinQ k , bk

n

k 1

38

Does not smear

S3

Point lasts

S5

Does not roll

S2

S1

S2

S3

S4

S5

->

->

->

->

->

not important at all

minor importance

some importance

strong importance

very strong importance

Erasure residue

O

Hexagonality

S2

Lead dust

generated

Length

Easy to hold

Customer Requirements

(WHATS)

Time between

sharpening

Importance of

WHATS

Engineering Characteristics

(HOWS)

X

O

X

X

O

X

X

X

-> weak relationship

O -> medium relationship

X -> strong relationship

39

• Q k S f k , k 1,2,..., n is the average linguistic

quantifier (the weights of the OWA operator),

t 1

with f k Int 1 k

;

n

• S f k is the f(k)-th level of the linguistic scale (for

example Sf(k) = S1 if f(k) = 1);

• Int(a) is a function which gives the integer

closest to a;

• t is the number of scale levels;

• n is the sample size.

40

• Number of scale levels: t = 5 (S1, S2, S3, S4, S5).

• Sample size: n = 10.

• Ordered elements: S5, S5, S5, S4, S4 , S3, S3, S3, S2, S1.

• The weights are:

Q(1) = S1,

Q(2) = Q(3) = S2,

Q(4) = Q(5) = Q(6) = S3,

Q(7) = Q(8) = S4,

Q(9) = Q(10) = S5.

41

OWA= Max MinS1 , S5 ,MinS2 , S5 ,MinS2 , S5 ,MinS3 , S4 ,MinS3 , S4 ,

MinS3 , S3 ,MinS4 , S3 ,MinS4 , S3 ,MinS5 , S2 ,MinS5 , S1 S3

42

Thank you for your

attention!

… any questions?

43

• Rossetto S., Franceschini F., “Quality and innovation: A conceptual

model of their interaction”, Total Quality Management, v. 6 n. 3,

1995, pp. 221-229.

• Franceschini F., Rossetto S., “The problem of comparing

technical/engineering design requirements”, Research in

Engineering Design, v. 7, 1995, pp. 270-278.

• Franceschini F., Rossetto S., “Design for Quality: selecting product's

technical features”, Quality Engineering, v. 9, n. 4, 1997, pp. 681688.

• Franceschini F., Zappulli M., “Product's technical quality profile

design based on competition analysis and customer requirements:

an application to a real case”, International Journal of Quality and

Reliability Management, v. 15, n. 4, 1998, pp. 431-442.

44

• Franceschini F., Rossetto S., “QFD: how to improve its use”, Total

Quality Management, v. 9 n. 6, 1998, pp. 491-500.

• Franceschini F., Terzago M., “An application of Quality Function

Deployment to industrial training courses”, International Journal of

Quality and Reliability Management, v. 15, n. 7, 1998, pp. 753-768.

• Franceschini F., Rupil A., “Rating scales and prioritization in QFD”,

Total Quality Management, v. 16, n. 1, 1999, pp. 85-97.

• Franceschini F., Rossetto S., “QFD: an interactive algorithm for the

prioritization of product's technical characteristics”, Integrated

Manufacturing Systems, v. 13, n. 1, 2002, pp. 69-75.

• Franceschini F., Advanced Quality Function Deployment, St. Lucie

Press/CRC Press LLC, Boca Raton, FL, 2002.

45

• Franceschini, F., Galetto, M., Varetto, M., “Qualitative ordinal

scales: the concept of ordinal range”, Quality Engineering, v. 16, n.

4, 2004, pp. 515-524.

• Franceschini, F., Galetto, M., Varetto, M., “Ordered samples control

charts for ordinal variables”, Quality and Reliability Engineering

International, v. 21, n. 2, 2005, pp. 177-195.

• Franceschini, F., Brondino, G., Galetto, M., Vicario, G., “Synthesis

maps for multivariate ordinal variables in manufacturing”,

International Journal of Production Research, v. 44, n. 20, 2006, pp.

4241-4255.

• Franceschini F., Galetto M., Maisano D., Management by

Measurement: Designing Key Indicators and Performance

Measurements. Springer, Berlin, 2007.

46