Transportation Problem: Operations Research Presentation

advertisement

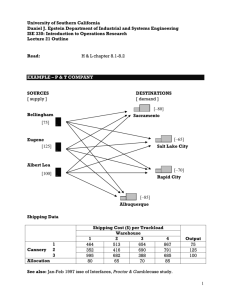

Operations Research TRANSPORTATION PROBLEM Consider… One of the main products of the P&T Company is canned peas. The peas are prepared at three canneries (Bellingham, WA; Eugene, OR; Albert Lea, MN) and then shipped by truck to four distributing warehouses in the western US (Sacramento, Salt Lake City, Rapid City, Albuquerque). Because shipping costs are a major expense, management is initiating a study to reduce them as much as possible. For the upcoming season, an estimate has been made of the output from each cannery, and each warehouse has been allocated a certain amount from the total supply of peas. This information (in units of truckloads, along with the shipping cost per truckload for each cannery-warehouse combination is provided. There are a total of 300 truckloads to be shipped. Determine which plan for assigning these shipments to the various cannery-warehouse combinations would minimize shipping costs. What does the problem formulation look like? Minimize Z = 464x11 + 513x12 + 654x13 + 867x14 + 352x21 + 416x22 + 690x23 + 791x24 + 995x31 + 682x32 + 388x33 + 685x34 Subject To: x11 + x12 + x13 + x14 = 75 x21 + x22 + x23 + x24 = 125 x31 + x32 + x33 + x34 = 100 x11 + x21 + x31 = 80 x12 + x22 + x32 = 65 x13 + x23 + x33 = 70 x14 + x24 + x34 = 85 With: xij >= 0, (i = 1, 2, 3; j = 1, 2, 3, 4) Exercise! The Move-It Company has two plants producing forklift trucks that then are shipped to three distribution centers. The production costs are the same as the two plants, and the cost of shipping for each truck is shown for each combination of plant and distribution center: Distribution Center 1 2 3 Plant A $800 $700 $400 Plant B $600 $800 $500 A total of 60 forklift trucks are produced and shipped per week. Each plant can produce and ship any amount up to a maximum of 50 trucks per week, so there is considerable flexibility how to divide the total production between the two plants so as to reduce shipping costs. However, each distribution center must receive exactly 20 trucks per week. Initialization 1.) From the rows and columns still under consideration, select the next basic variable (allocation) using one of the criteria noted next slide. 2.) Make that allocation large enough to exactly use up the remaining supply in its row or the remaining demand in its column (whichever is smaller). 3.) Eliminate that row or column (whichever went to 0). If tied, choose the row. 4.) If only one row or only one column remains under consideration, then the procedure is completed by selecting every remaining variable associated with that row to be basic with the only feasible allocation. Otherwise, return to step 1. Criterion Northwest Corner Rule: Begin by selecting x11. Thereafter, if xij was the last basic variable selected, then next select xij+1 if source I has any supply remaining. Otherwise, select xi+1j Vogel’s Approximation: For each row and column remaining under consideration, calculate the arithmetic difference between the smallest and next-to-the-smallest unit cost still remaining in that row or column. In that row or column having the largest difference, select the variable having the smallest remaining unit cost. Russell’s Approximation: For each source row i remaining under consideration determine the largest unit cost cij (call this x) still remaining in that row. For each destination column j remaining under consideration determine the largest unit cost cij still remaining in that column (call this y). For each variable xij not previously selected in these rows and columns calculate z = cij – x – y. Select the variable having the largest (in absolute terms) negative value of z. Optimality Derive ui, vj by selecting the row having the largest number of allocations, setting its ui = 0, and then solving the set of equations cij = ui + vj for each (i,j) such that xij is basic. If cij – ui – vj >= 0 for every (i,j) such that xij is nonbasic, then the current solution is optimal and stop. Otherwise, go to an iteration. Iteration 1.) Determine the entering basic variable: select the nonbasic variable xij having the largest (in absolute terms) negative value of cij – ui – vj. 2.) Determine the leaving basic variable: Identify the chain reaction required to retain feasibility. Basically, increase the value of the entering variable and see what happens to the other basic variables when you attempt to retain feasibility. The basic variable that gets driven to 0 first becomes the leaving basic variable. From this you can determine the “donor” cells (ones that decrease) and “recipient” cells (ones that increase, including the entering variable). 3.) Determine the new feasible solution: add the value of the leaving basic variable to the allocation of recipient cells and subtract from donor cells.