Training - 5S+1

1

LT6

5S + 1

CONTINUOUS IMPROVEMENT

OFFICE

Session Agenda

• Introduction

• Background and History

• Components and Implementation

2

Introduction

• 5S + 1 is a method to improve and sustain workplace organization

• Represents 6 disciplines for maintaining a visual workplace

(visual controls and information systems).

• These are foundational to continual improvement and a manufacturing strategy based on "Lean Manufacturing"

(waste removing) concepts.

• Reduces clutter

• Reduces the time it takes to look for tools and equipment

• “A place for everything and everything in its place”

• Improves how the operation appears to customers – always be “tour ready”

• Creates pride in the workplace

• Many companies have a standard that any tool must be able to be found within 60 seconds.

3

Background and History

• Taiichi Ohno created the original “4S” concept of workplace organization and visual control at Toyota during the early 1950’s.

• The concept was further refined into “5S” during the 1960’s and 1970’s.

• U.S. manufacturers added a sixth “S” for “safety” during the 1990’s.

• The 5S+1 tools were recently modified by

Gwendolyn Galsworth to include “Visual

Workplace” disciplines.

4

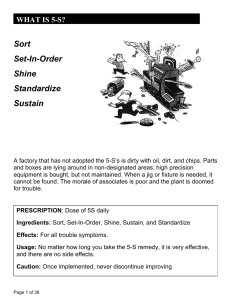

Elements of 5S + 1 and Visual Workplace

– Sort

– Scrub/Shine

– Secure Safety

– Select Locations

– Set Locations

– Sustain

5

Elements of 5S +1 & Visual Workplace

• Sort

– Remove all unnecessary materials and equipment

• Scrub/Shine

– Clean everything, inside and out

• Secure Safety (often called “6S” or “5S + 1”)

– A safety commitment in all activities

• Select locations

– Decide where everything remaining should be

• Set locations

– Put remaining items in place, provide “anchors”

• Sustain

– Establish policies and procedures to ensure 5S

6

– Training, daily activities, audits

Types of Waste

• Defects

• Over-Production

• Waiting

• Non-Utilized Talent

• Transportation

• Inventory

• Motion

• Extra Processing

• Other Wastes:

– Inappropriate Systems

– Wasted Utility Resources

– Wasted Materials

7

The Good, Bad and the Ugly

• First the Bad and the Ugly - Life Without 5S

8

The Good – After 5S + 1

9

After 5S + 1

• Clear, shiny aisles

• Color-coded areas

• Posted processes, metrics and other current information

• Always “customer tour ready”

10

5S + 1 Examples

11

Before 5S

After 5S - Cleaned, organized and drawers labeled (less time and frustration hunting)

Sort

• Identify clutter and disposition

• When in doubt, move it out

• Red tag exercise (more later)

12

Scrub/Shine

• Clean everything, inside and out

• Prevent dirt and contamination from reoccurring

• Remove outdated material (like old posted charts, news, and metrics!)

• Results in

– Fewer breakdowns

– Greater safety

– Product quality

– More satisfying work environment

13

Shine Check Sheet

• Ceilings

• Aisles

• Workstations

• Corners, under equipment

• Loading docks

• Walls

• Doors

• Pillars, posts

• Floors

• Machines

• Conveyance equipment

• Plumbing, sinks

• Cabinets, shelves, racks

• Carts, Racks

• Drawers, storage bins

• Fixtures, power boxes

14

5S Examples - Shine

• The area is cleaned as the work is performed (best) and\or there is a routine to keep the work area clean.

15

Safety

• Does not replace the existing site safety plan

• During 5S audits also review all areas for safety

16

Select Locations

• Make it obvious where things belong

– Lines

• Divider lines

• Outlines

• Limit lines (height, minimum/maximum)

• Arrows show direction

– Labels

• Color coding

• Item location

– Signs

• Equipment related information

• Show location, type, quantity, etc.

• Consider your “Value Field”

17

Select Locations Check Sheet

• Equipment

• Machines

• Small tools

• Dies

• Jigs

• Bits

• Conveyance equipment

• Cleaning equipment

• Materials

• Raw material

• Supplies

• Parts

• Work-in-process

• Finished goods

• Shipping materials

• Cleaning supplies

• Furniture

• Cabinets

• Benches, tables

• Chairs

• Carts

• Shelves

• Racks

• Other items

• Charts, graphs, bulletin boards

• Pens, pencils

• Work clothes

• Helmets

• Work shoes

• Trash cans

18

5S Examples

See the difference?

• Sort - All unneeded tools, parts and supplies are removed from the area

• Scrub/Shine – Cleaned/Painted

• Select & Set Locations - A place for everything and everything is in its place

19

Set Locations & Standards

• Establish guidelines for the team 5-S conditions

• Make the standards and 5-S guidelines visual

• Maintain and monitor those conditions

20

Typical Team Standards

• Sort

– Amount of inventory

– Tools that belong in the area

– How often to remove scrap

• Straighten

– Location of aisleways

– Location of tools, equipment

• Shine

– Cleaning schedule

– Maintenance tasks

– Checklist of what to look for as cleaning is performed

21

Sustain

• Determine the methods your team will use to maintain adherence to the standards

• 5-S concept training

• Before and after photos

• Checklists, standards and procedures

• Daily 5-minute 5-S activities

• Monthly 5S Audit

22

5S Implementation

1. Begin reviewing your areas for 5S

2. Discuss 5S with each of your groups (brief group meeting)

3. Red tag sorting process (one time)

4. Brief, simple daily 5S individual activity (“just look around”)

5. Brief 5S checklist or procedure for each area

6. Monthly 5S audit beginning __________

• Area Lead plus at least one person from outside that area

• Post results (I will look for them!)

• Review results with your group

• Take corrective action

23

© 2007 Superfactory™. All Rights Reserved.

Red Tag Process

• One-time activity to remove or disposition clutter

• To be started within two weeks of this training

1. Identify clutter, unused equipment, etc

2. Fill out and attach red tag

3. Note in red tag log

4. Must disposition Red Tags within (XX) days

24

Red Tag Example

Item Tagged by: ________________________

Name of Item: __________________________

Date: _________________________________

Location of Item: ________________________

Reason for Red tagging

(Check One)

Obsolete

Defective

Scrap

Trash

Unneeded

Used once/day

Used once/week

Used < once/month

Seldom Used

Use Unknown

For Office Use Only:

Item No. ___________________________

Disposition:_________________________

__________________________________

25

Red Tag Hints

• Search

– Floors

– Aisles

– Operation areas

– Workstations

– Corners, under equipment

– Small rooms

– Offices

– Loading docks

– Inside cabinets

26

Red Tag Hints

• Look for unneeded equipment

– Machines, small tools

– Dies, jigs, bits,

– Conveyance equipment

– Plumbing, electrical parts

27

Red Tag Hints

• Look for unneeded furniture

– Cabinets

– Benches, tables

– Chairs

– Carts

28

Red Tag Hints

• Search these storage places

– Shelves

– Racks

– Closets

– Sheds

– Search the walls

– Items hung up

– Old bulletin boards

– Signs

29

Red Tag Hints

• Look for other unneeded items

– Work clothes

– Helmets

– Work shoes

– Trash cans

– Other

30

Red Tag Hints

• Look for unneeded materials

– Raw material

– Supplies

– Parts

– Work in process

– Finished goods

– Shipping materials

31

Visual Factory

• Mark-off the inventory locations

• Mark-off equipment/machine locations

• Mark-off storage locations (cabinets, shelves, tables)

• Visually indicate amount of allowed inventory

• Keep metrics, wall charts, and other information current

• Label all cabinets, shelves, etc with their contents

• Posted production status, upcoming jobs

32

33