One of the many projects I have completed for Mercy Clinic

advertisement

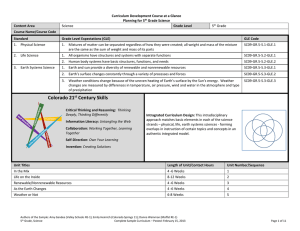

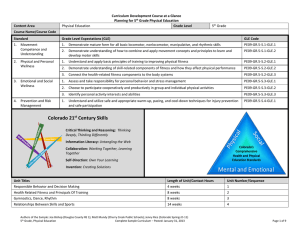

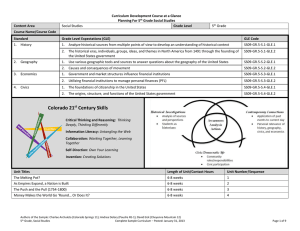

Lean Tools: 6S 5-S Workplace Organization The foundation of a process is a clean and safe work environment. 5-S Standards are the foundation that supports all phases of Lean. The system can only be as strong as the foundation upon which it is built. When fully implemented, 5-S helps to reduce errors, increase productivity, improve quality, improve response time, and improve worker morale. It’s strength is dependent upon the employee’s commitment to maintaining it. 2 5S System and Visual Management Separate the needed items from the un-needed items. Sort 5S Set In Order Arrange needed items based on where they will be used. Shine Maintain the work area for the needed items. Standardize Sustain Ensure all S’s are consistently followed. Maintain all S’s. The 6th ‘S’ is for SAFETY! 3 Sort When in doubt, remove it! STEP 1: Clarify what is needed. Segregate what is needed and what is not needed No hoarding! STEP 2: Dispose of things that are not needed. Discard or donate what is not needed Ask questions like how many of these have you used in the last week or month? STEP 3: With items that are needed, segregate according to frequency of use. Use once a day versus use once a month 4 Set in Order A place for everything, and everything in its place. STEP 1: Decide place for storage. With unnecessary clutter removed, the team determines appropriate locations for items that are needed to “add value.” Those items used several times per day should be closer than those items used once a month STEP 2: Set up markings (Boundary Lines) for storage locations. Clearly mark and arrange everything neatly so what is needed can be easily found. STEP 3: Make upkeep easy. 5 Shine Clean to inspect, inspect to detect, and detect to correct. STEP 1: Conduct overall ‘Shining’. Clean up personal and working environment so there are no areas untidy with dirt or other clutter. Top to bottom cleaning and inspection. By touching and observing equipment as they clean, team members can spot early signs of trouble before they cause break downs, accidents, and defects. STEP 2: Improvement plans to prevent dirtiness. 6 Safety How do we be safe and productive?..effective?...with good quality? STEP 1: Resolve all safety issues STEP 2: Change things likely to cause injury, stress, or overburden STEP 3: Check existing safety equipment 7 Standardize You can see the perfection ! STEP 1: Make the new standards obvious to everyone. Turn proven temporary methods for keeping the workplace uncluttered into permanent visual methods. STEP 2: Maintain the conditions to the previous 3 S’s. 8 Sustain Sustain the Gain. Pride of ownership! STEP 1: Develop a system to determine if the gains have been sustained. Turn proven temporary methods for keeping the workplace uncluttered into permanent visual methods. STEP 2: Develop a system to bring forward future suggestions and trial changes. Board was placed in co-worker break room to visually see if gains have sustained. They are to insert current picture each month. 9 Conducting a 6S – Points to consider Consider the area’s work schedule and determine the best day and time to conduct the 6S. You can also pull everything out of an area and only bring back in needed items. Respectfully challenge each other so that only needed items are kept. Involve team members who represent every role that utilizes the workspace. Be sure the coworkers from the area understand the purpose and value of a 6S before you start. No one should be surprised. 10 5S Examples The following slides illustrate how 5S can be utilized in a variety of projects to remove process clutter, improve efficiency, and reduce NVA-E and NVA-W. 11 Problem: No space left in storage, storing supplies on the floor in other areas Space was utilized by storing things no longer needed …Some mistake 6S for simple housekeeping … it actually builds a solid framework for visual management From This To This! Lab Storage 12 Standardize Exam Room Before After 13 Respiratory Therapy Dept Before After Removal of unneeded items (cabinets, shelves, cart) Replaced storage shelves with open and visible shelving (shelving was stored in another department’s storeroom!) Identified what should be stored in each area by colored dots, magnetic shelf labels, different colored walls and tote sizes 14 Respiratory Therapy Dept Removed unneeded items (cart, shelving, sink, old books) Replaced storage shelves with open and visible shelving Moved most used items to eye level Before After 15 Respiratory Therapy Dept Before After Removed unneeded items (exam table, extra supplies, old files Utilized different tote sizes and labels to indicate where every item should be placed Utilized clear storage totes in order to see what was stored there 16 6S at Work A place for everything and everything in it’s place Condensed from 3 drug sample closets to 1 Before After 17 From your first cycle of 6S 1.) You want a showcase: You want at least one department / work area in your hospital that vividly captures the vision and the function of visual order to inform and inspire others to “get on board”. 2.) You want results: Improvement of the key performance indicators in your pilot area(s) that are attributable to visual order. Such indicators as: productivity, yields, defect, re-work, scrap levels, safety, on-time delivery, and overall lead time. 3.) You want to learn about the process: You want to learn about the implementation process itself - to see what works, how people react, and what is needed and realistic to expect in terms of outcome and support. 6S Exercise In your group, identify the 6S improvements that could be applied to the simulation process or to a work area you interact with daily. Identify what improvements need to be made at each of the following steps: Sort Set in Order Shine Safety Standardize Sustain 19