Total Cost Accounting A Leading

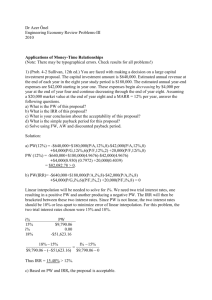

advertisement

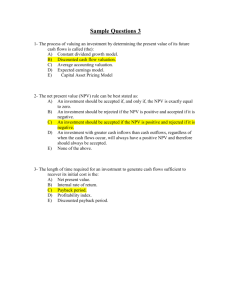

Economics of Sustainability When money speaks, nobody cares for the grammar! Economics of Sustainability Efforts Detailed financial / profitability analysis of sustainability projects necessary to get top management commitment Translate the project outcomes in $ and ¢ Available Tools: Environmental Management Accounting or Total Cost Accounting Traditional Profitability Analyses: Payback Period, Net Present Worth, Internal Rate of Returns Environmental Management Accounting (EMA) Combination of life cycle analysis and activity based costing approaches Identify total (internal) costs associated with environmental activities Make apparent the financial burden created by material, energy, inventory and other operational inefficiencies Provide additional inputs for business decisions Based on “true” operational costs Current ENV Cost Situation Most ENV/OEHS costs often treated as fixed and unavoidable ENV costs not directly allocated to activity or process generating wastes and emissions Do You Know All Your ENV Costs ? 50 to 70 % of ENV costs for a typical facility are HIDDEN in general overhead accounts Administration Legal Facilities Maintenance Transportation The Significance of ENV Costs What gets measured gets managed Simply quantifying costs will lead to questions Potentially identify savings Distinction between some “environmental” and “operating” costs may not be obvious But costs are costs and need to be managed Total Environmental Cost Components Conventional (or Direct) Costs Potentially Hidden (or Indirect) Costs Opportunity Costs (or Production-related costs) Contingent (or Future) Costs Intangible (or Less Real) Costs Direct Costs Storage,handling, and disposal of residuals Pollution control equipment costs Onsite and offsite Capital costs Operation and maintenance Required Permits Applications and fees Potentially Hidden Costs Waste packaging and shipping Insurance Premiums Monitoring, recordkeeping, and reporting Facility audits Qualifying contractors Potentially Hidden Costs (Cont’d.) Training and meetings Environmental data management Equipment and product labeling Legal support Lost Opportunity Costs Operational shutdowns Loss of operating flexibility Loss of raw materials Unrealized product revenue Unrealized new product ideas May be more significant than other costs Contingent Costs Future compliance costs Future liability costs Future remediation costs Unexpected shutdown costs Property damage Personal injury damage Natural resource damage Intangible Costs Corporate image Working conditions Employee morale Relationship with customers and suppliers Relationship with investors & shareholders Relationship with regulators Cost Data Gathering Identify and define environmental categories and activities relevant to your operations Initially focus on tangible costs Let’s Begin With ABC..... Activity Based Costing Create a “cost” pool for each “activity” or transaction that can be identified as a cost driver Gather data relating to activity centers and cost drivers (i.e.,true reasons for costs) More complex operations will have more cost drivers Traditional Cost Accounting System Modified Cost Accounting System Profitability Analysis CP Costs incurred Benefits obtained • Simple payback; • Net Present Value; • Internal Rate of Return Profitability Analysis Simple Payback Period Simplest method of profitability analysis Payback Period (yrs): (Total Investment) / (Total Annual Savings) There are two main problems with the payback period method: It ignores any benefits that occur after the payback period, and so does not measure profitability It ignores the time value of money Net Present Value Takes into account time value of money PV: Present Value FV: Future Value = Net Savings – (Investments + Operational Costs) i: Rate of interest in the market n: No. of years Internal Rate of Return Often used in capital budgeting It is the interest rate that makes net present value of all cash flow equal zero. Essentially, this is the return that a company would earn if it expanded or invested in itself, rather than investing that money elsewhere. Example: Recycling Project in Paper Industry Capital Costs Saveall Equipment = $345,985 Saveall and White Water Pump Materials = $374,822 Piping, Electrical, Instruments and Structural Installation = $397,148 Engineering = $211,046 Contingency = $140,403 Equipment Life = 15 years Borrowing Rate of Interest = 15% Total = $1,469,404 Annual Savings* = $350,670 Profitability Indicators Simple Payback period 4.19 years Net Present Value: Years 1-15 = $359,544 Internal Rate of Return: Years 1-15 = 21% *Annual operating cash flow before interest and taxes Thank You Very Much! http://www.unep.fr/pc/retail/