PPT 5.1MB - Energy Efficiency Opportunities

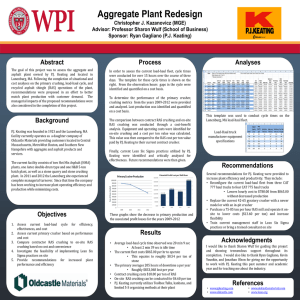

advertisement

POTTERS INDUSTRIES EEO DATA ANALYSIS PROGRAM Who are Potters Industries • Potters Industries is part of the internationally owned PQ Corporation • The PQ Corporation is the world’s largest silicate manufacturer and a major player in the engineered glass bead market • PQ Corp. spans over 50 countries employing more than 3000 people • The 3 local (Australian) manufacturing facilities are split into two business units , “Industrial Chemicals” and “Engineered Glass Materials” • EGM Glass Beads Sunshine Hollow Microspheres Dandenong • Industrial Chemicals Alkali Silicates Dandenong Sydney • The Dandenong facility operates in 24/7 while the Sunshine and Sydney facilities are 5 day operations. • Combined, the sites employ approx. 65 personnel Energy History & Data Systems History • Energy is a major operational cost and accordingly energy reduction programmes have been a focus for the business for >10years • As a result, some energy monitoring and analysis systems were in place prior to the EEO program and many projects had already been completed Systems • Existing • Monthly data capture (Essentially Total Energy Use Only) • Live process data but NOT energy capture • Data Analysis - such as measuring production efficiencies vs. costs Our Approach The EEO program guidelines provided the outline of our approach by ensuring the following actions:1. Gaining “Commitment” from Senior Management 2. Establishing an “Energy Team” 3. Developing a Program Plan covering the “Key Elements” of the Program 4. Establishing “Program Structure” 5. Setting “Timelines” for actions Energy Management Groups For each Business sector we established Steering Management Groups which included an Energy Management Champion to ensure the overall program did not stall. Each Team had responsibilities and accountabilities assigned. Example: Project Phases We utilised an existing model for the project. This model similar to the EEO Model Collect Data Review & Report Analyse Data Each of these project parts have tools associated with them (Not Discussed Here) Implement Project Identify Projects Prioritize Projects Planning & Support Systems To ensure the program was controlled we established a Project Plan and had existing support systems to assist manage any information developed such as: Policies Procedures & Instructions Records or Data Information Without these systems we may not have been able to complete the program in the timeframe we did Data Collection Due to an internal personal change Potters joined the EEO program late and we’re behind schedule in data collection. Establishing the Baseline To enable analysis of usage patterns and identify the operational areas of greatest opportunity Potters embarked on a rigorous 3 month data collection program. • A log of all equipment which utilized electricity was generated. • This log encompassed both operations and support and included every item from major cooling fans down to the coffee machine. • The energy rating (kwh) was recorded against each item and for those with VSD operational trends were analysed. • Data collection templates were generated for each part of the operation (Sales, Laboratory, Logistics, Furnace, Dissolvers, etc.). • Every staff member on site was responsible logging equipment use in their area on an hourly basis. It should be noted however that most staff updated once daily based on best recollection. Data Collection Model Data Collection VR6 BC7 CR8 EL9 VR11 DR12 BU14 EL15 BL242 VR174 VR175 EL176 SR25 CR23 SC28 EL29 SPL35 SR44 SR30 SR31 SR32 SC177 SC231 MAG267 CULLET CULLET CULLET CULLET CULLET CULLET CULLET CULLET CULLET CULLET CULLET CRUSHING CRUSHING CRUSHING CRUSHING CRUSHING CRUSHING CRUSHING CRUSHING CRUSHING CRUSHING CRUSHING CRUSHING CRUSHING CRUSHING CRUSHING CRUSHING Feeder Belt Conveyor Mighty Bite 12 Foot Elevator Barrel Dryer Feeder Barrel Dryer Barrel Dryer Burner 90 Tonne Elevator Cullet Baghouse Sprinkler system Area lighting x 6 Area Lighting x 35 Feeder tube Feeder tube Scalper Elevator Scalper Primary Crusher Screw Bucket Elevator Top Splitter Rotex 0 Rotex 1 Rotex 2 Rotex 3 Primary O/R Screw Fines Screw Fines Magnet Establishing the Baseline (continued) After 3months of data collection we had gathered nearly 1.2million data points. 4:00 PM 0 0 0 0 0 0 0 0 5:00 PM 0 0 0 0 0 0 0 0 6:00 PM 0 0 0 0 0 0 0 0 7:00 PM 1 1 1 1 1 1 1 1 8:00 PM 0 0 0 0 0 0 0 0 9:00 PM 0 0 0 0 0 0 0 0 10:00 PM 0.5 0.5 0.5 0.5 0.5 0.5 0.5 0.5 11:00 PM 0.5 0.5 0.5 0.5 0.5 0.5 0.5 0.5 12:00 AM 1 1 1 1 1 1 1 1 1:00 AM 1 1 1 1 1 1 1 1 2:00 AM 1 1 1 1 1 1 1 1 3:00 AM 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 0 1 0 0 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 0 0 1 1 1 1 1 1 1 1 1 1 0 0 1 1 1 1 1 1 1 1 1 1 0 0 1 1 1 1 1 1 1 1 1 1 0 0 1 1 1 1 1 1 1 1 1 1 0 0 1 1 1 1 1 1 1 1 1 1 0 0 1 1 1 1 1 1 1 1 1 1 0 0 1 1 1 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 1 1 1 0 0 1 1 1 1 1 1 1 1 1 1 0 0 1 1 1 1 1 1 1 1 1 1 0 0 1 1 1 1 1 1 1 1 1 1 0 0 1 1 1 1 1 1 1 1 1 1 0 0 1 1 1 1 1 1 1 1 1 1 0 0 Scada Code / Power Rating Month Week Date 2011 2011 2011 2011 2011 2011 2011 2011 2011 2011 2011 2011 5 5 5 5 5 5 5 5 5 5 5 5 19 19 19 19 19 19 19 19 19 19 19 19 5/05/2011 5/05/2011 5/05/2011 5/05/2011 5/05/2011 5/05/2011 5/05/2011 5/05/2011 5/05/2011 5/05/2011 5/05/2011 5/05/2011 Time Year Plant Area Data Collection Establishing the Baseline (continued) The data was compiled and the total energy use for both electricity and gas was compared against the supplier invoiced quantities. Despite inaccuracies involved in manual collection the relative usages aligned very closely for both natural gas and electricity. Site Electricity kWh Site Energy Gas GJ Sunshine 98% 102% 98% Dandenong Sydney 99% 104% 100% NA NA POTTERS Total 99% * Sydney was not included due to the relative size and energy use. Due to the good alignment it was agreed this data could be considered a valid representation of energy use patterns. Data Analysis - Trending • Establishing the Baseline (continued) • Trend data was used to isolate events that may skew data, for example, maintenance shutdowns, breakdowns, etc. Data Analysis - Trending • Operational efficiency for each product type was also conducted using trends. This information allowed costs to be assigned to products which in turn could be used to develop sales and marketing strategies • Trending also showed the benefits of timer controlled heating in administrational areas. • Clarified the relationship no link between shift and efficiency. ENERGY USE by PRODUCT TYPE 70 60 50 40 30 20 2/08/2011 29/07/2011 27/07/2011 25/07/2011 21/07/2011 19/07/2011 15/07/2011 Visimax 13/07/2011 11/07/2011 8/07/2011 6/07/2011 4/07/2011 30/06/2011 Medium 28/06/2011 24/06/2011 22/06/2011 20/06/2011 16/06/2011 14/06/2011 Econo 9/06/2011 7/06/2011 3/06/2011 1/06/2011 30/05/2011 26/05/2011 24/05/2011 20/05/2011 18/05/2011 16/05/2011 12/05/2011 10/05/2011 6/05/2011 4/05/2011 0 2/05/2011 10 Data Analysis - Pareto • Establishing the Baseline (continued) • Once the data was cleaned we used Pareto Analysis to confirm the areas which consumed the most energy. • Unsurprisingly the furnace operation accounted for 59% of the energy with the Hollows operation accounting for 35%. Sum of kWH Usage Rotary dryer Motor New Baghouse Blower fan Spray Drier Stack Fan Screener Baghouse Transfer Fan Pit Pump Quality/Manufacturing Admin Heating Finance Admin Aircon/Heating Sales / CS Offices - Heating/Cooling Cumulative % Blower Fan Cooling Fan A Chiller recirculator pump Cooling Fan B MCC AirCon Main Baghouse Fan Motor Scrubber fan Atomiser Push fan Kaeser Compressor #1 Atlas Compressor Hot Water Suction fan Boiler Burner Zone 2-5 Burners Flash Popper Burner Spray Drier Burner Burners Usage 80 100% 70 90% 60 80% 50 70% 60% 40 50% 30 40% 20 30% 10 20% 10% 0 0% Cumulative % Energy Use Data Analysis - Pareto • Pareto charts were used to rank the energy use of specific parts of each operation and help focus energy saving efforts. • The operation burners accounted for 92% of all energy use Data Analysis - Correlations • We used correlations to examine possible links and preconceived ideas about energy use such as perceived links between ambient temperature and operational efficiency. Is there value in running more during the day? Burner1 SP Burner2 SP Ambient Burner1 SP Burner2 SP Ambient 100% 10% 100% 20% -33% 100% • Correlations between operational conditions and energy input were also explored. One example was the link between Tower pressure and burner set points. Managing Pressure better allows lower set points and less energy input Pressure Burner 1 SP Burner 2 SP Pressure Burner 1 SP Burner 2 SP 100% 5% 100% 82% -45% 100% Projects • The Pareto clearly showed that the most value could be obtained by reducing gas use in the burners with a secondary focus on major motors and compressors • Projects identified for further investigations as a result of the program were as follows: • Waste heat boiler • Furnace Heat Recovery • Hollows Heat Recovery • Push Fan Replacement Complete • Office Heating/Cooling • Hollows Burner Replacement • Boiler Burner Control Upgrade • Suction Fan Proposed for 2013 • Furnace Burner Design Ongoing Questions ??