Riding the Small Wave in Manufacturing to a Diverse Economy and

advertisement

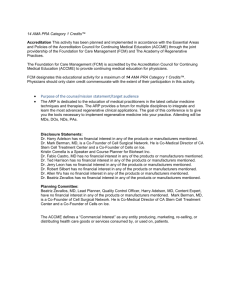

Riding the Small Wave in Manufacturing to a More Diverse Economy and More Good Jobs Susan Christopherson Department of City and Regional Planning smc23@cornell.edu The Resurgence of Manufacturing and the New Location Calculus • A weak dollar – dropped 26% between 2002 and 2008 • Gradual and anticipated increases in transportation costs – oil at over $100 a barrel for the foreseeable future • Lower wages in the US; higher wages in China • Problems with quality control in China • Intellectual property concerns in China • Low energy costs in US • Foreign direct investment has increased (19% in 2008) Manufacturers are Taking a Second Look at The US “Manufacturers are beginning to recognize that many of the factors they previously based their off-shoring manufacturing and supply decisions on most heavily, such as component price and transportation costs, have dramatically increased over the last few years—and those seemingly initial cost savings are no longer so big.“ The Manufacturing Institute 2011 Some Recent Examples in Transportation and Industrial Equipment • Caterpillar has repatriated manufacturing of construction excavators, boosting investment in facilities in Texas, Arkansas and Illinois. • GE's appliance unit is in the middle of a four-year, $600 million plan to build up its manufacturing presence in Louisville, Kentucky, adding some 830 new jobs. The success of these efforts will depend on the quality of regional supply chains. Great Lakes Metros Have Benefited from This Trend Upstate New York cities are among 40 least affected by the great recession. According to the Brookings Institution 2009 analysis of the Great Lakes metros’ unexpected resilience in the face of the great recession, many industrial centers led the recovery from the massive downturn: “With increases in job growth, GMP, and housing prices, the worst of the recession may be behind both Madison and Syracuse. Steady, if not yet growing, employment and increasing output, along with rising home prices, provides some indication that Buffalo, too, could be on the road to recovery.” Two Distinct Definitions of the “Problem” From a Labor Supply Perspective: A ten-year long shortage of workers with mid-level, technical skills From a Labor Demand Perspective: Inadequate job creation to employ unemployed or underemployed workers with few credentials What Are the Challenges? • Manufacturing job growth will occur in small and medium-size companies. • Few small manufacturing companies are investing in labor skills, information technology or productivity-increasing process innovations (The American Small Manufacturers Coalition). • There is a serious skill shortage in manufacturing in SMEs, who cannot compete with Global OEMs for skilled labor in manufacturing regions What Happened as SMEs Replaced Old RoutineManufacturing Giants? Source: Treado, Carey et al. “Sustaining Pittsburgh’s Steel Technology Cluster” According to Dan Swinney of The Chicago Manufacturing Renaissance: “The character of work has changed dramatically”. The employers he works with are willing to train and pay high wages for the “talent” they need. Though entry-level wages may be low, the salaries of workers who see manufacturing as a profession rather than just a job rise very rapidly. What Can We Do in the Short Term? To meet the demand for middle-skill, technical workers: • Create more “earn to learn” programs (which also create jobs). • Insure that community colleges in all states can provide noncredit job training. • Support manufacturer demands for stackable, mobile credentials. What Can We Do in the Short Term? To increase the propensity of manufacturers to return to the US and labor demand among manufacturers who do return. • Pass hiring incentives focused on SMEs in expanding manufacturing sectors. Focus on payroll expansion not hiring. • Train ED policy makers respond to the full range of costs that manufacturers need to consider in making location decisions. Assess the wide range of assets that may attract manufacturers to repatriate production. • Evaluate how direct and indirect federal and state policies can contribute to accelerating location of manufacturing jobs in the US. This includes energy policies. Total Cost Model for Offshore Sourcing Adapted from Archstone Consulting Delivery Costs Supplier Price and Terms Unit Price Logistics •Labor •Direct materials •Management •Overhead •Capital Amortization •Local taxes •Manufacturing •Local regulatory compliance • • • • Terms • • • Net payment Volume Discounts Free Goods In-country transport Ocean/air freight Destination transport Packaging Operations & Quality Costs In-plant Material Inventory •Intra-plant demand •Safety stock •Handling •Overhead •Warehousing & O/H Region Specific • • Duty VAT Supply Chain • • Inventory maintained within Satellite warehousing & O/H Quality • • • Quality validation Quality management Failure costs Other Costs Standard •Risk •Qualification •Local tax incentives Situational • • • • • • Procurement staff Broker fees Infrastructure Exchange rates Training Tooling/molds Customer Specific • • Unique services Unique capabilities What Will Build “Stickier” Manufacturing? • Build capacity and global markets in our manufacturing technology “eco-systems” – electronic packaging, photonics, environmental systems, energy storage, sensors. Develop efficient multi-modal freight “villages” in urban sites. • Transform State Centers of Excellence to serve small companies rather than the multi-national dinosaurs. • Develop Manufacturing Renaissance plans for cities along the lines of Chicagoland and the Bay Area, supporting self-organized groups of SME manufacturers. • Encourage DESIGN initiatives (eg. competitions in engineering) that respond to the needs of small manufacturers in basic industries. Our Ultimate Goals? 1. To take advantage of the “small wave” of interest in manufacturing in the US, driven by comparative advantage in factor costs. Magnify the advantage. 1. To build on the factor input cost advantage to create technologybased ecosystems made up of SMEs with global markets. 2. To make US-based manufacturing “sticky” because it is more efficient and closer to the end markets. Riding the Small Wave in Manufacturing to a More Diverse Economy and More Good Jobs Susan Christopherson Department of City and Regional Planning smc23@cornell.edu