NWMOC WhAT IS

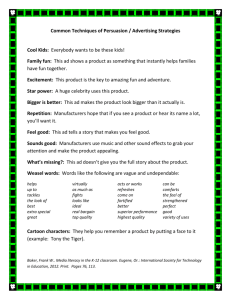

advertisement

What is NWMOC? The Northwest Wisconsin Manufacturing Outreach Center is part of a nationwide network of Manufacturing Extension Partnership (MEP) centers and is located on the campus of University of Wisconsin-Stout, Wisconsin’s Retirements Polytechnic University. The NWMOC provides at-your-location services by and western Wisconsin. The NWMOC is part of UW-Stout’s Discovery Center, To develop competitive manufacturing companies in our region by bringing positive the NWMOC, Frank Borg, marketing and public relations manager, has retired. change and growth to our clients. be missed,” said Larry Blackledge, NWMOC director. experts deliver integrated services to manufacturers in 33 counties in northern our mission After nine years of service with Stout Technology Transfer Institute (STTI) and “Frank’s breadth of knowledge and extensive community contacts will certainly seasoned practitioners with expertise in manufacturing management. These NWMOC A nnual R eport 2010-2011 Doris Faber has worked for UW-Stout for 31 years. For the last 21 years, she which provides applied research to foster discovery and innovation-based solutions. The NWMOC wishes a fond farewell to some outstanding employees. Director has successfully served the centers of the STTI, in particular the NWMOC, as a In partnership with Chippewa Valley, Northcentral, Nicolet Area, financial specialist and grant coordinator. “With her cheerful and open attitude, Western and Wisconsin Indianhead Technical Colleges and UW-Stout; the Doris was a pleasure to work with.” center delivers the training and technical assistance needed to improve and In the past year, the Northwest Wisconsin Manufacturing Outreach Center (NWMOC) expanded services into new and exciting areas. As part of the Discovery Center, we were able to connect manufacturers to the resources of UW-Stout, providing significant results for our clients and real-world projects for students and faculty. This has enabled the NWMOC to reach beyond our traditional bounds. It has been, and continues to be, a rewarding experience. We wish Frank and Doris well deserved enjoyment in their retirements. grow manufacturing businesses. LETTER FRO M TH E Our largest funding partner, the National Institute of Standards and Technology, began Why NWMOC? moving into new territory as well. In addition to its traditional assistance in creating The number one reason clients chose the NWMOC in the past year was a culture of continuous process improvement, they are addressing an increased expertise, followed by fair cost and solid reputation. The center’s manufacturing emphasis on the growth of manufacturers to add new jobs, new products and new specialists have extensive backgrounds and work experience in industry. They markets. In collaboration with the Discovery Center and other area resources, we are have lived the battles. The specialists are practitioners who have the expertise well positioned to work on projects that include new designs for existing products, new to review an operation and develop an understanding of clients’ competitive product concepts, new markets for existing products, and new product prototyping and issues and future goals. commercialization. NWMOC produces measurable results and substantial returns for Wisconsin manufacturers and taxpayers. • Over the past four quarters, the federal investment in NWMOC alone produced gains for manufacturers resulting in impacts of $69 for every What is New federal dollar invested. Wausau Paper Company, Rhinelander “NWMOC had helped us begin a culture of change that will make us a more competitive, more profitable organization.” – Steven Moore, Director of Manufacturing • This investment translates into a cost of less than $1,900 for every job created or retained 1 — far below other economic development initiatives. 1 • NWMOC delivers more impact with fewer federal dollars. Figure cited in a 2005-06 Review of State Economic Development Programs for the Joint Legislative Audit Committee The primary area of client demand continues to be in process improvement or Lean NWMOC's new Computer Simulation Service eliminates the guesswork by manufacturing. I don’t see this changing in the foreseeable future. This area of quantifying the ROI and impacts before the investment of valuable time and practice continues to be an important and thriving part of the NWMOC as we help money. The process can help companies answer tough questions and make manufacturers grow and become sustainable operations. investments with confidence. Chippewa River Industries, • Implement process improvements? In the next year the NWMOC will focus on penetrating the market further. To accomplish chippewa falls • Hire more staff? this, we will look to expand our products, services and delivery methods to best provide • Purchase equipment? our manufacturers with the support required to excel in key success categories. We will • Add another production line? continue to build on what we and our partners are currently doing, and we will work on “Through NWMOC’s computer simulation, they determined the optimal number of employees on our production lines, ultimately resulting in increased efficiency within our systems.” scaling the services to fit the manufacturers in our region. To schedule a live demonstration contact Kelly Sullivan at 715.232.5261 or by email at sullivank@uwstout.edu. Larry Blackledge NWMOC Director – Bill Peterson, Director of Operations and Sales NORTHWEST WISCONSIN MANUFACTURING OUTREACH CENTER A resource of the Discovery Center at University of Wisconsin-Stout School of Education 866.880.2262 • http://nwmoc.uwstout.edu www.uwstout.edu/programs/mscte NWMOC Results The NWMOC uses a national survey house, Turner Marketing, to monitor client results on completed projects. Manufacturers in the NWMOC region reported more than $29.5 million dollars impact in new and retained sales; cost savings and investments in plants and equipment, information systems or software, workforce practices or employee skills, and other areas of business. NWMOC Services M eet a C ritica l N eed NWMOC Survey Results rolling 4 quarters Since 1994, NWMOC has helped to create and save more than 3,600 state manufacturing jobs, according to results documented by companies. In the midst of the recession, NWMOC’s services created and retained 319 jobs last year. Examples include: 75 jobs retained – Bill Bockes, President Nolato Contour, Baldwin Four new jobs and 10 retained jobs In 2010-11, the NWMOC: • Served 101 manufacturers by a completed technical assistance activity or public event • Delivered 114 technical assistance projects to area manufacturers and businesses • Sponsored 13 public events attended by 482 people • Achieved client-reported impacts of more than $29.5 million • 319 jobs created or retained, 189 jobs saved and 130 new jobs reported • Achieved a customer satisfaction rating of 8.62 on a 10-point scale with 10 being very good Jobs Created/Retained created Schuette Metals, Wausau 200 20 retained jobs 150 “The expertise of the [NWMOC] Manufacturing Center has been a big help.” – John Peterson, President Merit Gear, Antigo “Probably the greater benefit from the 5-S event — beyond the obvious workplace improvements — was seeing the people working together as a team … That right there will improve the overall performance of the department in the future.” retained – John Herrmann, 25 new jobs and Plant Superintendent 0 opportunities and challenges. NWMOC serves 3,584 manufacturing enterprises in 33 counties in northern “You’d be a fool not to try the NWMOC services. It doesn’t cost much when you consider what you get!” Client Profile Location: Superior, Wisconsin Years in Business: Since 1997 Number of Employees: 180 Products: Manufacture and market innovative products for the hunting industry NWMOC Projects and western Wisconsin. This region has a multitude of small manufacturers.2 – Bob Matarelli, • Ninety-nine percent of manufacturers in these counties are small and Lean Coordinator/ Principles of Lean Manufacturing, 5S, VSM, E!WW, A3 Problem Solving, Total medium-sized firms, employing fewer than 500 people Manufacturing Engineer Productive Maintenance, Simulation (majority of projects done in partnership with • More than 70 percent employ fewer than 10 people Harris InfoSource, www.selectoryonline.com 17 16 0 67 30 201020102010 2011 Q2 Q3 Q4 Q1 84 84 Conference Success Story: NWMOC’s fourth annual Manufacturing Advantage Conference theme was Sustaining Profitability: People, Process, Planet. “We provided our conference attendees with valuable tools and information to achieve and sustain profitability, including methods surrounding the people within their organization, the processes they practice on the plant floor and throughout the company, and opportunities for sustainability practices that improve their bottom line,” said Larry Blackledge. The 2011 conference kicked off with preconference industry tours of Cardinal Glass and Andersen Windows in Menomonie. Following the tours, nearly 100 Situation conference attendees enjoyed the networking reception “A Taste of Wisconsin” at When NWMOC project managers called on Field Logic, their timing could not have the Dunn County Fish and Game pavilion in Wakanda Park. Food and beverages been better. Field Logic wanted an expert opinion on establishing baselines and from food processors and distributors across the region were featured. developing a systematic way for the company to move forward. In the last 10 years, Field Logic has had tremendous growth. Results • Increased production in Block® Target division by 20 percent • Improved Hurricane™ Target layout by 30 percent • Required increased quality from supply chain vendors • Experienced cost savings of $65,000 • Increased investments by $28,500 • Used specialized recycled materials to fill bag targets Project Communication is always important especially during periods of rapid growth, which is why nearly all employees have participated in Lean 101 training and implementation. Field Logic began their lean journey by targeting their Block® Target division. Production in that area has increased by 20 percent on average. Conference attendees heard from two keynote speakers: John R. Brandt, CEO XeteX, Inc., La Crosse “At the beginning, this seemed intimidating. However, the NWMOC personnel were very knowledgeable, accommodating and worked well with our people in applying Lean methods. Overall, these improvements should help us retain existing and attract new clients and obtain more orders. Highly recommended.” – Keith Hohenstein, President Their Hurricane™ Target area layout has been improved by 30 percent. Field Logic’s Broadhead Arrow division experienced significant growth with a demand that exceeded their ability to supply. Because they did not have all SOPs — standard operating procedures — in place, training new employees was challenging. Each division undergoes a 5S audit monthly. The production workspaces have been redesigned to eliminate bottlenecks and to streamline work textile industries to fill their bag targets. At first this specialized scrap was sorted 21 2011 M anufacturing Advantage Northwest Wisconsin Workforce Investment Board FY10-11) flow. Field Logic is also practicing sustainability by using specialized scrap from 100 50 to compete globally. Exports, sustainability and new product innovation are key Field Logic, Superior Fie ld Logic H unts Lean Success $4,314,500 total savings Johnson Electric Coil, Antigo “With the NWMOC, you don’t get what you paid for; you get much, much more!” resources and expertise to implement the scope and scale of change necessary 2 $6,142,300 total investment $18,999,000 total sales client National studies show that small manufacturers often lack the internal and cut by hand, but they now use a machine that they designed and built to cut the scrap, which is much more efficient. The company designs and builds many of its own conveyors and machines. Dental Crafters, Marshfield “For the money we spent, I can’t think of anything that’s been more beneficial with immediate improvements on our bottom line.” – Bob Slominski, Co-owner of The MPI Group, who spoke about manufacturers remaining competitive in the future; and Donald R. McNeeley, president and CEO of Chicago Tube and Iron Corp., who presented the “Sustainability of Profit: The Ultimate Measure.” Conference attendees articulated the value provided from the excellent keynote speakers, the variety of breakout sessions and the significance of getting together with other manufacturers to network and share ideas and concerns. This year’s Manufacturing Advantage Conference will be held May 21-22, 2012.