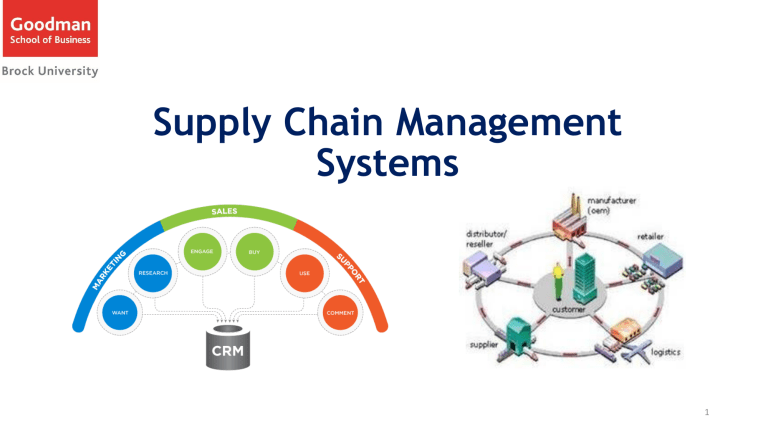

Supply Chain Management Systems 1 Learning Objectives 1. Describe the three components and the three flows of a supply chain. 2. Identify popular strategies for solving different challenges of supply chains. 3. Explain the utility of each of the three major technologies that support supply chain management. 2 Outline Supply Chains and Supply Chain Management Information Technology Support for Supply Chain Management 3 Supply Chains Supply chain is the flow of materials, information, money, and services from raw material suppliers, through factories and warehouses, to the end customers. • It includes the organizations and processes that create and deliver products, information, and services to end customers. Flows of the supply chain • Material: physical products, raw materials, supplies, etc. that flow along the chain. o • • Material flows also include reverse flows (or reverse logistics)—returned products, recycled products, and disposal of materials or products. A supply chain thus involves a product life cycle approach, from “dirt to dust.” Information: data related to demand, shipments, orders, returns, and schedules, as well as changes in any of these data Finance: money transfers, payments, credit card information and authorization, payment schedules, e-payments, and credit-related data. Video 4 Supply Chains GENERIC SUPPLY CHAIN Supply chain visibility • The ability for all organizations in a supply chain to access or view relevant data on purchased materials as these materials move through their suppliers’ production processes and transportation networks to their receiving docks. Supply chain efficiency 5 SUPPLY CHAINS iPhone Supply Chain Bombardier supply chain 6 Supply Chain Management Supply chain management (SCM): to plan, organize, and optimize the various activities performed along the supply chain. Interorganizational information system (IOS): information flows among two or more organizations. • Reduces costs of routine business transactions • Improves quality of information flow by reducing or eliminating errors • Compresses cycle time in fulfilling business transactions • Eliminates paper processing and its associated inefficiencies and costs • Makes transfer and processing of information easier for users 7 PUSH MODEL AND PULL MODEL Push model (aka make-to-stock), the production process begins with a forecast (an educated guess) as to customer demand. • • • Predict products customers will want and the quantity of each product. Produces the amount of products in the forecast in mass and sells, or “pushes,” those products to consumers. Under and over forecast create problem Pull model (aka make-to-order), the production process begins with a customer order. • Companies make only what customers want, a process closely aligned with mass customization. 8 PROBLEMS ALONG THE SUPPLY CHAIN Poor customer service Poor quality product High inventory costs Loss of revenues The problems along the supply chain arise primarily from two sources: 1. Uncertainties 2. The need to coordinate multiple activities, internal units, and business partners 9 THE BULLWHIP EFFECT The bullwhip effect is erratic shifts in orders up and down the supply chain 10 Solutions to Supply Chain Problems Vertical Integration is a business strategy in which a company purchases its upstream suppliers to ensure that its essential supplies are available as soon as they are needed. Using inventories • Just-in-time (JIT) inventory system – systems that deliver the precise number of parts, called work-in-process inventory, to be assembled into a finished product at precisely the right time. Information sharing – can be facilitated by electronic data interchange and extranets. Vendor-managed inventory (VMI) – occurs when the supplier, rather than the retailer, manages the entire inventory process for a particular product or group of products. 11 Information Technology Support for Supply Chain Management Electronic Data Interchange (EDI) - a communication standard that enables business partners to exchange routine documents electronically. • • • • • • • Minimize data entry errors Length of messages are shorter Messages are secured Reduces cycle time Increases productivity Enhances customer service Minimizes paper usage and storage Limitations • • • Sometimes business processes must be restructured EDI is being replaced by XML-based web services Multiple EDI standards exist 12 Information Technology Support for Supply Chain Management • An extranet allows external business partners to enter the corporate intranet, via the Internet, to access data, place orders, check the status of those orders, communicate, and collaborate. It also enables partners to perform self-service activities such as checking inventory levels. Extranets use virtual private network (VPN) technology to make communication over the Internet more secure. Major benefits: • • • • • Faster processes Information flow Improved order entry and customer service Lower costs Overall improved business effectiveness 13 Information Technology Support for Supply Chain Management Portals and Exchanges – Web services Portals enable companies and their suppliers to collaborate very closely Procurement portals: automate the business processes involved in purchasing or procuring products between a single buyer and multiple suppliers Distribution portals: automate the business processes involved in selling o distributing products from a single supplier to multiple buyers 14 SUMMARY Supply chain is the flow of materials, information, money, and services from raw material suppliers, through factories and warehouses, to the end customers. o o o o three components: upstream, internal, downstream three flows: material, information, financial Two major challenges: demand forecast, bullwhip effect IT support for supply chain management: EDI, extranets, portals and exchanges Electronic data interchange (EDI) is a communication standard that enables the electronic transfer of routine documents, such as purchasing orders, between business partners. Extranets are networks that link business partners over the Internet. Corporate Portals offer a single point of access through a web browser to critical business information in an organization. 15