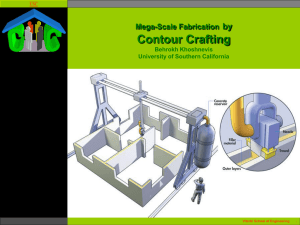

CRAFT - Contour Crafting

advertisement

USC CRAFT Center for Rapid Automated Fabrication Technologies Viterbi School of Engineering . USC Technology Demonstrations Industrial Parts & Molds Extraterrestrial Construction – Mega-Scale Layered Fabrication – Architectural Scale Models Freestanding Objects Public Art A House in a Day Economic Impact Social Impact Environmental Impact Regulatory Impact Grand Challenge Architectural Impact Extrudable Materials and Fabrication Modular Components and Assembly Employment Impact Integrated Software Systems Technology Thrusts Materials/Structures Composite Materials Fluid Dynamics Novel Structure Testing Sensing/Acting Systems/Processes Freeform/Geometry Dynamic Modeling and Control Embedding Capabilities during Fabrication Workflow & Logistics Planning Multi-Robot Coordination Real-Time Inspection Collaborative Design Mathematical Models of Fabrication Processes Feasible Geometry Reasoning 4D Modeling and Visualization System Performance Testing and Evaluation Fundamental Research Viterbi School of Engineering . USC CRAFT - Vision and Goals To develop the science and engineering needed for rapid automated fabrication of structures of various scales, up to very large objects such as buildings. The goal is a major breakthrough in Mega-Scale fabrication. Viterbi School of Engineering . USC Grand Challenge Building a custom-designed house in a day while radically reducing the costs, injuries, waste and environmental impact associated with traditional construction techniques. affordable housing for the 30 million U.S. households facing cost burdens or overcrowding; emergency housing for the 37 million/year victims of natural (and/or manmade) disasters; new styles of housing based on curved rather than straight surfaces; extraterrestrial buildings constructed from in situ materials; With national construction-related expenditures currently totaling close to $1 trillion annually, the potential impact is enormous. The goal: a revolution in housing construction Viterbi School of Engineering . USC Grand Challenge – a house in a day Economic Impact Employment Impact Social Impact Regulatory Impact Environmental Impact Architectural Impact Viterbi School of Engineering . Development Phases USC 2005 Multi-material nozzle assembly Building simple walls 2008 Sensor embedding/testing Multi-material simple structures Door/window with lintel/sacrificial support Flat roof construction Simple Simple Room Room Multi-cross Beam gantry Single Single Residence Residence Composites & reinforcement Multi-story Multi-story Multi-unit Multi-unit Digital construction material Multi-material delivery Process modeling Structure testing & modeling: Visual alignment Multi-robot Surface quality inspection Complex geometry Video logging Structural health monitoring Collaborative Assembly Structure feasibility Fabrication plan generation Reinforcement/Plumbing/Electrical Logistic planning Integrated Software Systems Intelligent CAD/CAM Modular Components and Assembly Control system: Basic Geometry Whole structure testing Community Community && Infrastructure Infrastructure Extrudable Materials & Fabrication Single material delivery 2010 Community-scale logistics planning Supportless roofs Walls w/complex geometry Modular reinforcement/ electrical/plumbing Material engineering 2009 Grand Challenge Single-Material nozzle/feed 2006 Viterbi School of Engineering . USC Technology Demonstrations Industrial Parts & Molds Extraterrestrial Construction – Mega-Scale Layered Fabrication – Architectural Scale Models Freestanding Objects Public Art A House in a Day Economic Impact Social Impact Environmental Impact Regulatory Impact Grand Challenge Architectural Impact Extrudable Materials and Fabrication Modular Components and Assembly Employment Impact Integrated Software Systems Technology Thrusts Materials/Structures Composite Materials Fluid Dynamics Novel Structure Testing Sensing/Acting Systems/Processes Freeform/Geometry Dynamic Modeling and Control Embedding Capabilities during Fabrication Workflow & Logistics Planning Multi-Robot Coordination Real-Time Inspection Collaborative Design Mathematical Models of Fabrication Processes Feasible Geometry Reasoning 4D Modeling and Visualization System Performance Testing and Evaluation Fundamental Research Viterbi School of Engineering . USC Interrelationships among the three research thrusts Architectural Design Logistics plan Integrated Software Systems Nozzle path plan Modular Assembly plans Components Inspection plan Supply Dispatch Indexed Video Log Structure design & Performance Requirements Extrudable Materials & Fabrication & Assembly Commands CC Hardware Hardware Feedback Sensory Data Visual Data Performance Restrictions Robot Predictive performance Viterbi School of Engineering . USC Extrudable materials & fabrication • Perform underlying basic research necessary to develop the materials and structures for automated mega-scale fabrication • Integrate materials into ultra-efficient structures • Integrate materials with delivery systems and robots from other thrusts Viterbi School of Engineering . USC Robotics fab, modular components & assembly • Perform research and develop various mono and distributed robots, tools, software and their integration into systems for assembling modules in situ to form functional attributes of structures • Robots’ locations, movements and working areas are dynamically changing along with environment. Develop a mathematical / geometric model of environment and a robot coordination protocol. • Perform the fundamental research in the modules to be placed internal to the extruded material that transform an extrusion into a functional wall or roof of a mega-scale structure. The modules that make a post-modern interactive structure include: • normal reinforcing, plumbing, and electricity conduits • Integrated communication, interactive sensing and displays • Integrate the Modules and Assembly Thrust with Extruded Materials and Software Viterbi School of Engineering . USC Viterbi School of Engineering . USC Embedding IT components Viterbi School of Engineering . USC Automated Painting Viterbi School of Engineering . USC Dynamic Control Flow Sensor Material Flow Computation Desired Material Flow - + Flow Control Law Material Flow Dynamics System Dynamics Position Sensor Commanded Position + Nozzle Control Law Gantry Motion Controller Nozzle Actuator Robot Wheel Motors Nozzle Forces Wheel Torques Gantry Dynamic Model Material Flow Nozzle Position & Orientation Gantry Position Position Sensors Viterbi School of Engineering . USC Goals • Perform the fundamental research and develop the software components for automating megascale fabrication • Integrate components with each other and with robots from other thrusts Viterbi School of Engineering . USC Viterbi School of Engineering . USC Industrial Sectors • • • • • • • Materials Construction Equipment Software Architects Real Estate Other application sectors Viterbi School of Engineering . USC Industrial Membership Industrial membership – 3 tiers – – – Senior Member - $100,000 Regular Member - $20,000 to $50,000 Technology Associate – small business Benefits to Industry – – – – – – – – – Seat on CRAFT ERC industrial advisory board – Senior Member Licensing (Senior Member – exclusive) Focused research projects Access to cutting edge research Access to center facilities and expertise for R&D projects Contact with graduate students Industry-University exchange program SBIR and STTR partnerships Industry-University Company Day – Senior Member Viterbi School of Engineering . USC Expressions of Support • Materials – – – – – – Degussa Corporation (committed) Maxit Group (committed) CEMEX Elotex ECRA (European Cement Research Academy) VDZ (German Concrete Research Academy) • Equipment – Siemens – John Deere – Parker-Hannifan Viterbi School of Engineering . USC Expressions of Support • Construction – Shea Homes – Parsons – Shimizu – Bechtel – Boeing (space) • Government – NASA (committed) – U.S. Army Viterbi School of Engineering . USC Expressions of Support • Architects – GL Forms (Greg Lynn) – Gehry Technologies – Cal-Earth • Real Estate – ConAm (builds low income housing in Mexico) – Regency Outdoor Advertising Viterbi School of Engineering . USC Management Plan Provost Executive Board: Provost (USC) Vice Provost, Research (USC) Dean of VSoE (USC) Director of ISI (USC) Dean of Engineering Scientific Advisory board Industrial Advisory Board Khoshnevis Director Student Leadership Council Rosenbloom Deputy Director Education Director Pre-College (K-12) Undergraduate & Graduate Outreach CREST/LSAMP EPICS/LINC/Fablabs Industrial Liaison Director Joe Sullivan Associate Director Grand Challenge Technology Thrusts: Extrudable Materials & Fabrication Modular Components & Assembly Integrated Software Systems (Neches/Rosenbloom) Industry Participation Faculty Mini-Sabbatical Technology Transfer Intellectual Property Viterbi School of Engineering . USC Thank you please visit www.ContourCrafting.org Viterbi School of Engineering .