Baseline_EA_Prebid_Conf - Bureau of Energy Efficiency

advertisement

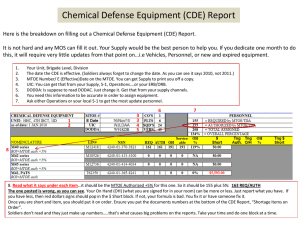

Pre-Bid Conference on BASELINE ENERGY AUDIT under Perform, Achieve & Trade (PAT) Scheme S P Garnaik Energy Economist Bureau of Energy Efficiency, Ministry of Power, GOI NATIONAL MISSION ON ENHANCED ENERGY EFFICIENCY (NMEEE) The National Action Plan on Climate Change was released by Honorable Prime Minister of India in June 2008 The Action Plan Outlines 8 Missions including National Mission on Enhanced Energy Efficiency (NMEEE) The Mission has outlined specific goals Chronology of Events of NMEEE 30th June 2008 : Hon’able PM releases the National Action Plan of Climate Change September 2008 : NMEEE endorsed by steering Committee, MoP 3rd October 2008 : Discussion on Draft outline in PMO 14th Nov 2008 : First consultation workshop at Mumbai 24th August 2009 : PM’s council on Climate Change approves NMEEE in principle 1st December 2009 : EFC recommends the implementation plan of NMEEE to Cabinet with a financial outlay of Rs. 235.35 crores May 2010 : Cabinet approves the financial outlay Ammendment to EC Act, 2001 passed in parliament NMEEE – Four New Initiatives NMEEE PAT Energy Intensive Industries Targets for Mandatory Energy Saving MTEE Energy Efficient Appliances BLY SEEP DSM EEFP Stimulate Funding for ESCOs FEEED Fiscal Instrument for EE PRGF VCF Public Procurement PAT Scheme : Background & Scope (1) Covers 685 designated consumers in 9 sectors All DCs consume about 240 mtoe energy i.e. about 60% of total energy consumption of the country Targets would be given to all DCs to achieve the same within a time frame • Achievement > Target E-Scerts • Achievement < Target Purchase E-Scerts / Penalty National Target = 10 mtoe at the end of 1st PAT Cycle ( April 2011 – March 2014) PAT Scheme : Background & Scope (2) Large band-with in Specific Energy Consumption (As per the BEE sectoral Study) Energy Usage Pattern is varying extremely due to various diversities Hence, the targets would be “Plant Specific” PAT Legal Framework •Furnish report of energy consumption to the Designated Authority of the State as well as to BEE (section 14(k)). •Designate or appoint an Energy Manager who will be in-charge of submission of annual energy consumption returns of the Designated Agencies and BEE (section 14 (l)). •Comply with the energy conservation norms and standards prescribed under section 14 (g) of the Act. •Purchase Energy Saving Certificates (ESCerts) for compliance to section 14 (g) in the event of default. The Act has been amended with the addition of new sub-section 14A to enable this and section 14A(2) allows such trading. EScerts are defined by adding a new subsection 2(ma). •Monitoring and Verification of compliance by Designated Energy Auditors (DENA) which will be prescribed the Government/ BEE under section 14A/13 (p) of the Act. •Excess achievement of the target set would entail issuance of ESCerts under section 14A(1). •Penalty for non-compliance being Rs. 10 lakhs and the value of non-compliance measured in terms of the market value of tones of oil equivalent by inserting a new section 26(1A). •BEE to be the overall regulator and dispute resolution agency and Energy Efficiency Service Ltd. (EESL) to be the process manager. BASELINE ENERGY AUDIT (Methodology of Scope of Work) Verification of Data Submitted by DCs • Production • All Energy Sources Item Data Unit Source of Data Production - MU / MT Document Purchased Elc. - MU Document All Energy Source - - Document [ Carefully investigate the source of data as the same source will be used during final verification ] BASELINE ENERGY AUDIT (Methodology of Scope of Work) Define the Plant Boundary (Gate-to-Gate Concept) • Physical Boundary • Process Boundary • Investigate the exclusions like colony power, construction related, internal transportation etc. with the submitted data [ The plant boundary needs to be discussed with Plant Management ] BASELINE ENERGY AUDIT (Methodology of Scope of Work) Develop Process Flow Diagram • Define sub-processes (Block Diagrams) • Put operating parameters like Temp / Pressure / Flow / mass etc. in the process flow diagram with designed value Develop the energy balance diagram of each sub-process Sub-System SS#1 SS#2 SS#3 SS#4 SS#5 SS#6 SS#7 Name Rectiformer Potline GAP Bake Oven Rodding Shop FTP Cast House Each Sub-System to be Studied for… Brief description of the sub-system Material Input & Output Energy (Elect./Thermal) Input & Output Technical Parameters for Energy Efficiency Listing of major static and rotating equipments Technology up-gradation since past years SEC BASELINE ENERGY AUDIT (Methodology of Scope of Work) Find out major energy consuming equipments in each sub-system • Investigate the technology • List out critical parameters which affect the efficiency and energy consumption • Operating vs. Designed value [ Measurements may be required at this stage. However, past energy audit reports, performance assessment reports may be referred to ] BASELINE ENERGY AUDIT (Methodology of Scope of Work) Example : Pot-line of an Aluminium Smelter Technology : Pre-Bake Parameters : Pot capacity Pot voltage Current Density ACD Anode Effect Factor BASELINE ENERGY AUDIT (Methodology of Scope of Work) Investigate All options related to • Waste Heat Recovery • Co-Generation • Fuel Switch • Use of EE equipment / System [ Detail discussion with management required at this stage ] BASELINE ENERGY AUDIT (Methodology of Scope of Work) Review the Past Energy efficiency Measures Technology Sub-System Category Energy Saving Monetary Saving Investment TU PM O&M Others Review the Future Energy Efficiency Approach/Strategy • Detail discussion with plant management required Preparation of Audit Report • Potential evaluation with tentative cost-benefit analysis Thanks …. For further information Please Contact S.P.Garnaik Energy Economist Bureau of Energy Efficiency Ministry of Power, GOI 4th Floor, Sewa Bhawan, R.K.Puram NEW DELHI – 110066 Ph.: 011-26179699 Fax :26178352 Email : sgarnaik@beenet.in Mission Goals Market-based approaches to unlock energy efficiency opportunities, estimated to be about Rs. 74,000 Crores By 2014-15: • Annual fuel savings in excess of 23 million toe • Cumulative avoided electricity capacity addition of 19,000 MW • CO2 emission mitigation of 98 million tons per year The PAT Scheme The market based mechanism to enhance the cost effectiveness in improving the Energy Efficiency in Energy Intensive industries through certification of energy saving which can be traded Market Transformation for Energy Efficiency (MTEE) Accelerating the shift to energy efficient appliances in designated sectors through innovative measures to make the products more affordable. Energy Efficiency Financing Platform (EEFP) Creation of mechanisms that would help finance demand side management programmes in all sectors by capturing future energy savings. Framework for Energy Efficient Economic Development (FEEED) Developing fiscal instruments to promote energy efficiency List of DCs Industry Sector Annual Energy Consumption Norm to be DC (mtoe) No. of Identified DCs Aluminum 7500 11 Cement 30000 92 Chlor-Alkali 12000 23 Fertilizer 30000 22 Pulp & Paper 30000 70 Power 30000 154 Iron & Steel 30000 110 Textiles 3000 197 Railways 30000 8 6 Bihar 4 23 West Bengal 4 Uttaranchal 39 U.P 6 Tripura Tamilnadu Rajasthan 41 Punjab Pondichery 46 Orissa 1 New Delhi 11 Meghalaya 57 Maharashtra 31 M.P 14 Kerala Karnataka 4 10 Jharkhand 16 HP Haryana 60 Gujarat Goa Chhattisgarh 6 Assam Andhra Pradesh State-wise DCs (2009-10) 99 74 57 47 25 4 Estimated Energy Consumption in DCs Sector Power (Thermal) Integrated Steel Cement Fertilizer Sponge Iron Textile Aluminium Paper Chlor-Alkali TOTAL MTOE 160.3 26.98 14.47 11.95 9.1 3.5 2.42 1.38 0.43 230.53 About 55% of DCs Contribute 96% of Total Consumption About 45% of DCs contribute rest 4% of Total Consumption Railways : 9.8 MTOE additional Target in PAT Target is defined as the % reduction of ‘Specific Energy Consumption (SEC)’ from Baseline value. All forms of Energy Plant System Boundary E S E C Product SEC = E / P Baseline SEC Reduction in SEC Target SEC Expressed in % Y1 Y2 Y3 P Energy Consumption (MToE)Share Among DCs Power (Thermal) Integrated Steel Cement 4% 6.2% Fertilizer 2% 1% Sponge Iron 0.6% Textile Aluminium Paper Chlor-Alkali 0.18% 5.1% 11.65% 69.23% Sectoral studies by BEE on ‘Setting Up of Sectoral Bandwidth for DCs’ have revealed the impact on SEC due to above diversities Sector Power plant Fertilizer Cement Range of SEC 2300 – 3400 5.86 – 9.11 665 – 900 Sponge Iron Gcal/T of Urea Kcal/Kg of Clinker (Thermal) 66 – 127 Integrated Steel kcal / kwh KWH/ T (Elect) 6.15 – 8.18 Gcal / tcs 4.4 – 7.6 Gcal / T (Thermal) 72 – 135 KWH/T (Elect) Aluminium (Smelter) 15875 – 17083 KWH/T Aluminium (Refinery) 3.28 – 4.12 MKcal / T of Alumina Pulp & Paper Textile 25.3 – 121 GJ/T 3000 – 16100 Kcal/kg (Thermal) 0.25 – 10 KWH/Kg (Elect) Chlor-Alkali 2300 – 2600 kwh/ T of caustic soda Reasons for Large Energy Usage Bandwidth The energy usage pattern varies widely in industries of a particular sector due to various diversities like -Scale of Production (Installed Capacities) - Use of Raw Material - Process Technology - Vintage - O & M Practices - Type of Product Output etc. a) a) a) a) a) a) Factors of Diversity Raw Material Input Quality of Raw Material / Fuel Process & Technology Final Product output Vintage Capacity Utililization Most Affected Sectors Pulp & Paper, Fertilizer, Power Plant, Textile All sectors Aluminium, Iron & steel, Chlor-Alkali, Paper Textile, Iron & Steel, Aluminium All Sectors All sectors Approach for Setting Targets Depends upon the Objective of the Scheme Total Saving Objective = 10 mMTOE • Setting Sector Targets based on available saving potential of Industries and Program Objectives Sector SN Energy Consumption Share of Consumption (mMTOE) 160.30 (%) 66.64% Apportioned Energy No. of identified reduction DCs (mMTOE) 6.66 1 Power (Thermal) 2 Iron & Steel 36.08 15.00% 1.50 110 3 Cement 14.47 6.02% 0.60 92 4 Fertilizers 11.95 4.97% 0.50 22 5 Railways (Approximated) 9.00 3.74% 0.37 8 6 Textile (Approximated) 4.50 1.87% 0.19 197 7 Aluminium 2.42 1.01% 0.10 11 8 Paper & pulp 1.38 0.57% 0.06 70 9 Chlor-Alkali 0.43 0.18% 0.02 23 Total 240.53 100.00% 10.00 154 687 Example : Baseline Estimation Name of Unit Place Total Installed Capacity ABC Ltd. XYZ 1600000 TPD Particulars Installed Capacity Actual Production (Cement) Unit Tonnes Tonnes Capacity Utilization Average in last 3 yreas Deviation from Average in last 3 yras Total Energy Input Total Energy Consumption Gate-to-Gate SEC w.r.t. cement Sector : Cement 2005-06 1200000.00 995000 2006-07 1200000.00 1146699 2007-08 1600000.00 1319800 2008-09 1600000.00 1325000 2009-10 1600000.00 1199000 % % % 82.92 95.56 82.49 74.94 3.01 82.81 80.08 3.41 Million Kcal 919757.4 985287.9 989421.4 1062985.0 977621.3 MTOE Kcal/kg 91976 924 98529 859 98942 750 106299 802 97762 815 Base Year 2009-10 Average Capacity Utilization % 80.08 Base line SEC (Gate-to-Gate) kCal/kg 789 6.42 Example : Target Setting (1) Production (in Tonnes) Plant Name Estimated SEC (in MTOE/ ton) Relative SEC Total Energy consumpti on (in MTOE) % Target To be Energy Saving 2005-06 2006-07 2007-08 Average production (MT) Plant1 3,62,793 3,68,867 3,78,157 3,69,939 1.275 1.272 1.277 1.274 1.000 4,71,455 X 4714.55x Plant2 3,58,954 3,58,734 3,59,213 3,58,967 1.364 1.365 1.362 1.364 1.070 4,89,546 1.07X 5238.14x Plant3 76,867 2,07,741 2,50,981 1,78,530 1.569 1.355 1.276 1.400 1.098 2,49,920 1.10X 2749.12x Plant4 66,347 73,008 99,406 79,587 1.425 1.452 1.408 1.428 1.121 1,13,679 1.12X 1273.2x Plant5 NA NA 37,635 37,635 NA NA 1.780 1.780 1.397 66,995 1.40X 937.93x Total 2005-06 2006-07 2007-08 Average SEC 13,91,594 14912.9X Example : Target Setting (2) Total Saving Target Saving X 14912.94x MTOE 62000 MTOE 4.15 Baseline SEC Target (%) To be SEC To be MTOE Plan1 1.274 4.15 1.22 4,51,889 Plan2 1.364 4.44 1.30 4,67,806 Plant3 1.400 4.56 1.34 2,38,527 Plant4 1.428 4.65 1.36 1,08,391 Plant5 1.780 5.80 1.68 63,111 Plant Name Total energy consumption at the end of 3 years (in MTOE) 13,29,725 Total present energy consumption (in MTOE) 13,91,594 Energy saving during the period 61,870 % Baseline SEC Number of Clusters depend upon the Bandwidth of Baseline SEC 10 9 8 7 6 5 4 3 2 1 0 Plant 1 Plant 2 Plant 3 Plant 4 Plant 5 Plant 6 Plant 7 Plant 8 Plant 9 Plant 10 Plant Baseline SEC 10 8 6 Cluster 2 Cluster 3 Cluster 1 4 2 0 Plant 1 Plant 9 Plant 4 Plant 3 Plant 6 Plant 10 Plant 8 Plant Plant 2 Plant 7 Plant 5 THE PAT SCHEME ….. Approach INDUSTRY (DC) Review of Present Energy Scenario & Bandwidth (Completed) Establish Baseline Development of Baseline Formats with System Boundaries Data Collection, Compilation & Analysis Verification of Data Set Targets for SEC Reduction Technology Transfer, EE Technology, R&M, R&D Achieve the Target Verification Protocol Trade the higher achieved saving through E-Certs Activity Flow Sheet Baseline & Target Setting Designated Consumer Baseline Format Design Finanalization of DC List Getting information through “Form#1” Prepare PAT Assessment Document (PAD) Getting Information Through Base Line Format Issue of e-Certs after successful M&V BEE Data Compilation/ Evaluation Verification of PAD through DENA Target Setting [Declaration of Base Year, Target Year ] Validation of PAD through DENA Recommendation for e-certification Target Setting for Power Station Variation in Net Station Heat Rate from Design Net Heat Rate Reduction Target for % deviation in the Net Station Heat Rate % Reduction Target in Net Station Heat Rate Upto 5% 10% 0.5 More than 5% and upto 10% 15% 0.75 to 1.5 More than 10% and upto 20% 20% 2.0 to 4.0 More than 20% 25% 5 and above Legal Framework •Furnish report of energy consumption to the Designated Authority of the State as well as to BEE (section 14(k)). •Designate or appoint an Energy Manager who will be in-charge of submission of annual energy consumption returns of the Designated Agencies and BEE (section 14 (l)). •Comply with the energy conservation norms and standards prescribed under section 14 (g) of the Act. •Purchase Energy Saving Certificates (ESCerts) for compliance to section 14 (g) in the event of default. The Act has been amended with the addition of new sub-section 14A to enable this and section 14A(2) allows such trading. EScerts are defined by adding a new subsection 2(ma). •Monitoring and Verification of compliance by Designated Energy Auditors (DENA) which will be prescribed the Government/ BEE under section 14A/13 (p) of the Act. •Excess achievement of the target set would entail issuance of ESCerts under section 14A(1). •Penalty for non-compliance being Rs. 10 lakhs and the value of non-compliance measured in terms of the market value of tones of oil equivalent by inserting a new section 26(1A). •BEE to be the overall regulator and dispute resolution agency and Energy Efficiency Service Ltd. (EESL) to be the process manager.