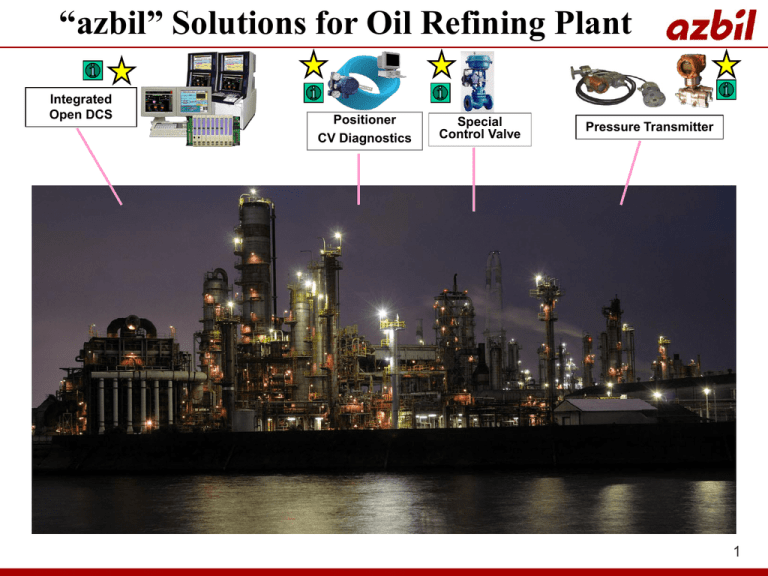

Oil Refining Plant

advertisement

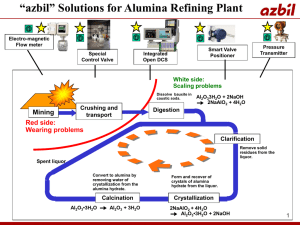

“azbil” Solutions for Oil Refining Plant Integrated Open DCS Positioner CV Diagnostics Special Control Valve Pressure Transmitter 1 azbil Open System Platform with a variety of Solution Packages Yamatake Solution Vision with System Platform PM-EX PM100 AMC Knowledge Power Alarm Analyst PREXION, Electric Shift Log Utility Optimization 3rd party system Integrated HMI DOPC DGFC DGPL PlantWalker-HV Field Client Ex Proof Field Client OperationAnywhere 2 MIB- For Manufacturing data visualization • Personalized window presentation images… For Manufacturing Manager For Manufacturing Stuff For Shift Leader •Distill data in multiple sources into useful data •Personalize useful data for each individual meeting their role and responsibility SOP Shift Log Batch History Plan/Performance Order/Ship Quality Labo Asset Data 3 PREXION – For production monitoring Infrastructure of production Information system Process historical information user can utilize the information at any time and any accuracy depending on their work. Operation Manageme nt Technology Control Site performance for Plant Manager Production Control Facility Management Production performance for Production Engineer Quality Control Process performance for Shift Leader 4 Knowledge Power - For Knowledge base operation To reduce incidents and mechanical losses, and to increase process uptime; Aware of problems in their respective areas (Early Fault Detection) Illustrate the impact to the overall business objectives Provide the “Site Best Practice” for operators (board and field) – Automate Procedures for flawless operation SOP for Transitional Operations and Recovery Activities Early Fault Detect Logic Trend Watching Knowledge Power (KP) provides; Early fault detection function Early fault diagnosis and Advice function Procedural automation function State-based Alarming function Easy to make, non programming Correlation Watching Early Fault Diagnosis Logic Procedure Automation and Guidance Knowledge of Experts Intelligent Alarm Automated DCS Operation 5 Standardized Modules Alarm Analyst - Correlation analysis Alarm Analyst R20 Correlation Analysis;Easy to build Knowledge-Base alarm & event model… unique technology From alarm & event historical logs, Correlation Analysis extracts ; Event groups consisted of the alarms and the operation actions in a process upset Propagation path Source origin Nuisance alarms Total counts in Alarm & Event group Information about Alarm & Event group structure Cause & Effect relationship – Cause of alarm flood or complex operation is estimated using order of events occurrence. 6 AT9000(GTX): Safety design The GTX is certified by TÜV to IEC61508 for single use in SIL2 Safety Instrumented Systems (SIS) and dual use in SIL3 in SIS. – To realize the SIS, the field devices must be required SIL. Typically the pressure transmitter is required to be SIL2. – Select “Safety transmitter” as option to be used as component of Safety Instrument System (SIS). The GTX is complied with IEC61508, Safety Integrity Level 2 (SIL2). Safe plant operation has been prime requirement for process automation especially in chemical, petrochemical and other industries. The SIS constitute one systematic means for safe plant operation. The specifications of such systems have been incorporated into the IEC61511 and 61508 standard and the standard and the standard has been adapted by many plants. 7 AT9000(GTX): Fast Response • Response time within 100msec – World’s best standards response time 110 Output [%] Pressure input 90 63.2% GTX output 70 50 30 93msec 10 -10 900 1000 1100 1200 1300 1400 Tim e [m sec] It can be used for pressure control around turbines required for fast response. 8 azbil Solution-oriented Control Valve Damages by fluids including hard slurry Ceramic trim angle vales are effective against hard slurry service. For FCC Plant (FCC: Fluid Catalytic Cracking unit) 9 azbil Solution-oriented Control Valve For detailed specification, please contact the sales representative in Azbil India. 10 Valstaff: Diagnostics function of control valve SVP has diagnostic algorithm and parameter of control valve operating condition. <Diagnostic parameters> Stick Slip Early detection of Total Stroke When the trend of these control valve abnormality parameters are monitored… Max. Travel Speed Establishment of control valve Travel histogram maintenance period Shut Count Cycle Count Threshold for alarm <Diagnostic system> HMI Application software Valstaff Customers can identify normality as the safety of the control valve. Customer can do predictive maintenance of control valve. Diagnosis algorithm Smart Valve Postioner 11