Global Standards for Food Safety Basic Course

advertisement

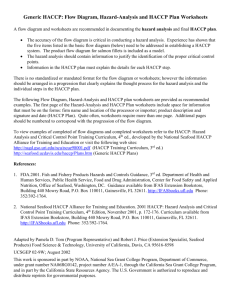

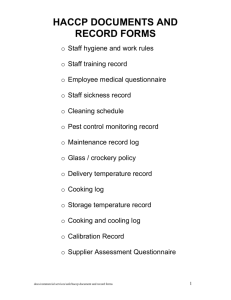

Global Standard for Food Safety Basic Course HACCPEuropa.com © 2010 Global Standards for Food Safety BRC In 1998 the British Retail Consortium (BRC), responding to industry needs, developed and introduced the BRC Food Technical Standard to be used to evaluate manufacturers of retailers own brand food products. It is designed to assist retailers and brand owners produce food products of consistent safety and quality and assist with their 'due diligence' defence, should they be subject to a prosecution by the enforcement authorities. HACCPEuropa.com © 2010 Global Standards for Food Safety BRC The Global standards for Food Safety has been developed to specify the safety, quality and operational criteria required to be in place within a food manufacturing organisation to fulfill obligations with regard to legal compliance and protection of the consumer. HACCPEuropa.com © 2010 Global Standards for Food Safety BRC retail members Aldi Asda Stores Ltd Burger King Limited Iceland Foods J Sainsbury plc Marks & Spencer Group plc Mc Donald’s Restaurants Ltd Morrisons Tesco plc Spar (UK) Limited The Co-operative Group HACCPEuropa.com © 2010 Global Standards for Food Safety Benefits Provides a single standard and protocol that allows an accredited audit by third party certification bodies Provides a single audit commissioned by the company, in line with an agreed audit frequency, that will allow the company to report upon their status to customer and other organisations as agreed, and can reduce time and cost Provides a measure by which food manufacturers and suppliers can demonstrate to potential customers a level of competence in food safety and quality systems HACCPEuropa.com © 2010 Global Standards for Food Safety Benefits Is comprehensive in scope, covering areas of quality, hygiene and product safety Addresses part of the legislative requirements of the food manufacturer/supplier, retailer and other customer. Companies may also use this Standard to ensure their suppliers are following good food safety management practices Requires ongoing surveillance and confirmation of the follow up of corrective actions on nonconformity to the Standard thus ensuring that a self-improving quality and product safety system is established. HACCPEuropa.com © 2010 Global Standards for Food Safety Principles A food business must have a full understanding of the products produced, manufactured and distributed and have systems in place to identify and control hazards significant to the safety of food. The Global Standard for Food Safety is based on two key components: 1. 2. Senior Management commitment HACCP (Hazard Analysis Critical Control Point) a step-by-step approach to managing food safety risks. HACCPEuropa.com © 2010 Global Standards for Food Safety Sections 1. 2. 3. 4. 5. 6. 7. Senior Management Commitment and Continual Improvement The Food Safety Plan – HACCP Food Safety and Quality Management System Site Standards Product Control Process Control Personnel with 319 clauses in total. HACCPEuropa.com © 2010 Global Standards for Food Safety Fundamental clauses Failure to comply with the statement of intent of a ‘fundamental’ clause leads to non-certification at an initial audit or withdrawal of certification at subsequent audit. This will require a further audit to establish demonstrable evidence of compliance. HACCPEuropa.com © 2010 Global Standards for Food Safety Fundamental clauses • Senior Management Commitment and Continual • • • • • • • • • Improvement, Clause 1 The Food Safety Plan – HACCP, Clause 2 Internal Audits, Clause 3.5 Corrective and Preventive Action, Clause 3.8 Traceability, Clause 3.9 Layout, Product Flow and Segregation, Clause 4.3.1 Housekeeping and Hygiene, Clause 4.9 Handling Requirements for Specific Materials – Materials Contain Containing Allergens and Identity Preserved Materials, Clause 5.2 Control of Operations, Clause 6.1 Training, Clause 7.1 HACCPEuropa.com © 2010 Global Standards for Food Safety 1. Senior management commitment and continual improvement The company’s senior management shall demonstrate they are fully committed to the implementation of the requirements of the Global Standard for Food Safety. This shall include provision of adequate resources, effective communication, systems of review and actions taken to effect continual improvement. Opportunities for improvement shall be identified, implemented and fully documented. HACCPEuropa.com © 2010 Global Standards for Food Safety 2. The Food Safety plan – HACCP The company’s food safety plan shall be based on a HACCP system which shall be systematic, comprehensive, thorough, fully implemented and maintained. Codex Alimentarius HACCP principles shall be used and reference shall be made to relevant legislation, codes of practice or guidelines. HACCPEuropa.com © 2010 Global Standards for Food Safety 3.5 Internal Audit The company shall audit those systems and procedures which cover the requirements of the Global Standard for Food Safety to ensure that they are in place, appropriate and complied with. HACCPEuropa.com © 2010 Global Standards for Food Safety 3.8 Corrective and Preventive Action The company’s senior management shall ensure that procedures exist to record, investigate, analyse and correct the cause of non-conformity against standards, specifications and procedures which are critical to product safety, legality and quality. HACCPEuropa.com © 2010 Global Standards for Food Safety 3.9 Traceability The company shall have system to identify and trace product lots and follow this through all raw materials (including primary and any other relevant packaging materials and processing aids), all stages of processing and the distribution of the finished product to the customer in a timely manner. HACCPEuropa.com © 2010 Global Standards for Food Safety 4.3.1 Layout, Product Flow and Segregation Premises and plant shall be designed, constructed and maintained. Procedures shall be in place to control the risk of product contamination and to comply with relevant legislation HACCPEuropa.com © 2010 Global Standards for Food Safety 4.9 Housekeeping and Hygiene Housekeeping and cleaning systems shall be in place which ensure appropriate standards of hygiene are maintained at all times and the risk of contamination is minimised. HACCPEuropa.com © 2010 Global Standards for Food Safety 5.2 Handling Requirements for Specific Materials – Materials Contain Containing Allergens and Identity Preserved Materials Where raw materials and finished products require special procedures for handling specific materials (e.g. material containing allergens or the requirement for Identity Preserved status such as Genetically Modified Organisms, assured organic status or special designated origin) these shall be in place to ensure that product safety, legality and quality are maintained. HACCPEuropa.com © 2010 Global Standards for Food Safety 6.1 Control of Operations The company shall operate procedures that verify that the process and equipment employed are capable of producing consistently safe and legal product with the desired quality characteristic, in full compliance with the HACCP food safety plan. HACCPEuropa.com © 2010 Global Standards for Food Safety 7.1 Training The company shall ensure that personnel performing work that affects product safety, legality and quality are demonstrably competent to carry out their activity, through training, work experience or qualification HACCPEuropa.com © 2010 Section 1 – Senior Management commitment - Main points • Fully committed to the implementation • Human and financial resources • Communication channels • Process review • Improvement HACCPEuropa.com © 2010 Section 2 – The Food Safety Plan HACCP - Main points • HACCP team - multi-disciplinary with • • • • designated and qualified team leader. Product description Process flow diagram – for each product, category or process Hazard analysis Critical Control Points – logical approach using decision tree, must eliminate or reduce to safe level HACCPEuropa.com © 2010 Section 2 – The Food Safety Plan HACCP - Main points • Monitoring – must be able to detect loss of control • Corrective action – procedures for unsafe products • Verification – through internal audits, review of hazard levels, complaints • Review – changes in ANY parameter HACCPEuropa.com © 2010 Section 3 – Food Safety and Quality Management System - Main points • Quality Manual • Costumer focus – determining customer needs, regular review - KPI • Internal auditing – programme of audits critical to safety, quality and legality, scheduled and frequency by risk assessment • Supplier focus – approval • Costumer complaints – investigation and recording HACCPEuropa.com © 2010 Section 3 – Food Safety and Quality Management System - Main points • Corrective and preventive action – including investigation of cause, implementation, review and verification • Traceability – ability to trace raw material to finished product and vice versa including mass balance, waste and rework • Crisis management –written guidance to staff , documented procedure HACCPEuropa.com © 2010 Section 4 – Site Standards - Main points • External site standards – compliance with • • • • • local regulations Internal site standards / staff facilities – designated to control risk of contamination Site security – prevent access by unauthorised personnel with visitor reporting system Utilities – use of water, ice, steam and air Equipment – suitably designed Maintenance – based on risk assessment with regular inspections HACCPEuropa.com © 2010 Section 4 – Site Standards - Main points • Foreign body control – appropriate storage for chemicals, metal control, glass register with procedures for glass breakage • Site hygiene – documented cleaning schedule carried out by trained personnel • Waste management – disposal must meet legal requirements • Pest control – use contractors or trained personnel HACCPEuropa.com © 2010 Section 4 – Site Standards - Main points • Storage and Transport – contract in place with sub-contractor; documented maintenance and hygiene procedures HACCPEuropa.com © 2010 Section 5 – Product Control - Main points • Product design, product development – new product must under-go production trials – HACCP based • Allergens and identity preserved materials – risk assessment for specific allergens; list of all allergens on site; training for allergen handling • Foreign body detection – justification for not providing HACCPEuropa.com © 2010 Section 5 – Product Control - Main points • Packaging – procedures to confirm • • • • specifications Inspection – monitoring of raw material Testing - accredited laboratories Positive Release – procedures based on risk assessment to ensure safe release by authorised staff Handling of non-conforming product – clear procedures for control HACCPEuropa.com © 2010 Section 6 – Process Control - Main points • Monitoring CCP, process monitoring – validation prior to production • Weight, count, volume control – legal requirements at country point of sale • Calibration – traceable calibration of all test and measurement equipment HACCPEuropa.com © 2010 Section 7 – Personnel - Main points • Training – all staff trained prior commencing work; additional training for CCP’s • Personal hygiene – requirements documented and communicated • Medical screening – reporting procedures for infections • Protective clothing HACCPEuropa.com © 2010 Global Standards for Food Safety Findings Audit reporting falls into the following distinct categories: • Critical non-conformances • Major non-conformances • Minor non-conformances HACCPEuropa.com © 2010 Any questions? HACCPEuropa.com © 2010