General Questions – Background

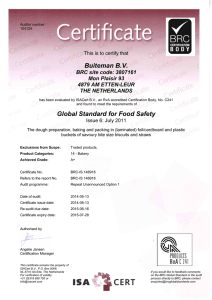

advertisement

BRC Global Standard for Food Safety Issue 6 Frequently Asked Questions BRC Food Standard Issue 6 Specific questions relating to the clauses and protocol of the Global Standard for Food Safety Issue 6 are detailed below. The BRC operate an enquiry service and if you are unable to find an answer to your particular question then please contact brcglobalstandards@brc.org.uk. General Questions – Background Audit Duration Audit duration - Will audit duration calculator change for unannounced audits? It is not expected that the time required for unannounced audits will be significantly different from that for the announced audit program i.e. typically a total audit time of 2 days. Background Risk assessment - What would you expect to see for a risk assessment, since the Standard now bases many of the requirements on this? Some sort of documentation would be expected to be seen as evidence of the thought process and conclusions made as to the risks to products. However, the principles and objectives behind 'risk assessment' are to ensure that the company has considered the issues pertinent to the requirements and can justify the reasons for their policy or procedures, responding to the challenge by an auditor. In some instances it would be appropriate to have a detailed document (along the principles of a HACCP plan) showing those considerations, an example may be the risk rating for suppliers and the subsequent approval process or the risks to product from physical contamination which would be included within the HACCP plan. However, F039 Issue 3 Released 4/11/2013 Issue 6 FAQ’s Page1 of 18 other requirements such as the policy on where beard snoods shall be worn could be evidenced in other ways such as a documented policy, to the understanding by staff and the reasoning behind this policy. This would include considerations of best practice within the industry and be open to challenge by an auditor. The need for a documented risk assessment would be particularly pertinent where you have decided not to adopt procedures for a particular requirement e.g. not wearing beard snoods in a particular area. Audit Reports What is meant by product safety rationale within the report? This provides users of the report with a clear overview of the basis for the safety of the products. It also ensures that the auditor and the site have carefully considered the rational for the safety of the products and that these have been addressed within the HACCP study Surveillance audit reporting - If a Certification Body undertakes a surveillance audit of a certificated site, for instance to follow up concerns, do they submit this report to the BRC? Where a Certification Body needs to carry out an additional visit to a site for instance for surveillance or investigation of an issue the CB will provide a visit report for the site. This will not be in the style of the official BRC audit report so that this is not confused with the full audit report. This report does not need to be uploaded to the BRC Directory, however should be available to BRC on request. Where the surveillance visit results in the suspension or withdrawal of a certificate, the BRC shall be notified. Scope Why have the BRC working group made changes to what can be included and excluded from the scope of the audit and certification. To effectively and consistently meet the requirements expected by the Standard sites need to operate a food safety culture and consistent way of working. It would generally be expected that the whole of a site should therefore be operating to the same standards and the certification scope apply to the whole site. The exclusions of some processes and areas can lead to double standards and is not within the spirit of what BRC certification is intended to demonstrate. Whilst exclusion of some product areas will be accepted the standard gives new guidance on conditions which must be met when making such exclusions. What are factored goods? F039 Issue 3 Released 4/11/2013 Issue 6 FAQ’s Page2 of 18 Factored goods are products which are purchased sold or distributed by a site but which undergo no process at the audited factory. Factored goods are often products bought in by a company to compliment the range of products manufactured at the site to provide a more comprehensive product range. Packing or repacking operations are classed as a process and would not be classed as factored goods. Scope Factored Goods - My Company handles mostly factored goods with a small amount of cheese cutting and packing. Therefore we have always had the Food Standard. Should I now go for the S&D Standard, in fact do I now need both? As factored goods are not included within scope it may be appropriate for the company to have both Storage and Distribution – including the wholesale module as well as Food standard for the cheese cutting and packing operation. The two audits may be carried out simultaneously where the auditor is suitably qualified to reduce costs. If a winery does most of their own bottling but uses a service provider for bottling their sparkling wine which then comes back to them for final approval and marketing can this be included within the scope? No. In this case bottling would be included in the scope but bottling of sparkling wine should be shown as an exclusion. Defining product scopes on the audit report - Can crop monitoring be included within the defined scope? The activities of growing are not within the scope of the BRC audits and are covered by various farm assurance schemes such as GLOBALGAP. We would not expect to see the word monitoring on the BRC audit report scope. Monitoring is part of the process of supplier and raw material approval which should be expected of all sites – all be it for fresh produce this activity may be a much more active engagement with the grower particularly where crops are grown under contract. New Factories When can we book an audit for our newly built factory? Manufacturing units that are newly built or ‘commissioned’ must ensure that systems and procedures in place are compliant before an initial BRC audit is undertaken. It is at the discretion of the company when they wish to invite a certification body to carry out an audit; however they must be able to demonstrate that systems and processes are well established, compliant and monitored. It is unlikely that full compliance can be satisfactorily demonstrated within a 3 month period from commencement of operation. A company may wish to consider a pre-assessment towards the end of this 3 month period. F039 Issue 3 Released 4/11/2013 Issue 6 FAQ’s Page3 of 18 With respect to a new production site within an established company, the site systems and procedures may reflect that systems already established with other sites within the company, but a full audit must establish compliance against BRC requirements for the new site. Head office audits What happens to the non-conformities raised at these audits – are they included as part of all the other sites audits or only the site on which the head office resides (if, of course, there is one production site close by or on the same premises)? Any non-conformities should be included in the report of the first site after the Head office audit. If any of these head office non- conformities are not corrected then these will be included in subsequent site reports. This is described in the standard on page 111 Standard Specific Questions Section 1 Management commitment Clause 1.1.7 What is defined as ‘a current issue’ of the Standard as required by clause 1.1.7? An ‘original’ issue of the Global Standard for Food Safety Issue 6 must be available on site. These are available through the BRC Bookshop in various languages, in print and as a PDF (where usage rules apply). This must not be a photocopy and should be made available to all relevant staff to ensure they understand The Standard’s requirements. Clause 1.1.8 When will a major non-conformity be awarded against maintenance of certification? A major non-conformity will be awarded where the company has not undertaken an audit within the audit due date (as indicated on the certificate). It is recognised that there may be specific circumstances where audits cannot occur within the certification cycle for instance packing of seasonal product, or access restrictions to the site and these are outlined within the Standard protocol Section III paragraph 12. Moving the audit date to a more ‘acceptable’ date for reasons of combining audits, lack of personnel or undertaking building work is not an acceptable reason for missing the due date. It is not a justifiable reason to delay audits where sites are not in full production, since there is a 28 day window in which the audit can occur and it is presumed that there will be occasions within that period where production is planned. Audits must however be undertaken whilst there are products are being manufactured. Justified reasons should be agreed with your F039 Issue 3 Released 4/11/2013 Issue 6 FAQ’s Page4 of 18 Certification Body prior to any delay with your audit booking. It is the certificated company’s responsibility to ensure a suitable audit date is agreed within the appropriate timescale. Where the company is not required to have certification by customers and where certificates have lapsed for more than 6 months re-entry to the BRC Certification scheme will be considered as a new application and the clause 1.1.8 will not apply. Clause 1.1.9 - who are defined as the ‘most senior’ production or operations manager on site to attend meetings? The objective behind this requirement is to ensure that the conclusions of the audit and any actions required to correct non-conformities are effectively understood, agreed and there is the authority to ensure these are carried out. Whilst it may be the case that the most senior personnel may be absent on the day of the audit, there will always be someone on site that will be responsible for the daily running of the site. Clause 1.1.10 What should happen if a declared corrective action plan for a root clause has not been implemented at the next audit? This would result in a non- conformity against clause 1.1.10 Where a non- conformity has recurred from the previous audit this may be raised both against the individual clause which has been failed and also may be evidence of failure against 1.1.10 Clause 1.2.1 How do you audit effectiveness of deputies This is not just about having a documented organisation structure but should include an assessment of how people are managed so that for instance there is cover for holidays. Deputies must be suitably competent to pick up tasks which they may need to deputise for. A deputy may be a more senior manager in the structure. Section 2 HACCP – Food Safety Plan Clause 2 What documentation do you need to keep for HACCP? You need to ensure that the information on which the HACCP plan is based is referenced and available on request by the auditor. This may include published literature on known hazards, codes of practice or legislation. You need to keep records of HACCP team meetings and the decisions which were reached. You should have documents to demonstrate how the decisions for establishing CCPs were reached. F039 Issue 3 Released 4/11/2013 Issue 6 FAQ’s Page5 of 18 Clause 2.1 How many people should make up the HACCP food safety team and what training do they require? The number of people on the HACCP food safety team should be pertinent to the size and structure of the company as the team should include representatives of each department with responsibility for operation of The Standard. It should not be too large and note that 1 person does not constitute a ‘team’. It would be expected that participants should have appropriate training, with particular regard to the team leader. This may be achieved through external, industry recognised training specific to HACCP but may equally be achieved by a good quality internal course. At the audit, the competency and understanding of the HACCP team would be assessed as well as the quality of the resultant HACCP plan. Note that if the HACCP plan has been prepared with the help of an external consultant, internal staff must still be fully conversant with the plan, principles and practices associated with it. Records need also to demonstrate the training of the external consultant in HACCP principles. Clause 2.10.2: … “checking and verification of electronic records associated with the monitoring of CCP’s…” – what would be the minimum required here as evidence of compliance? This is likely to depend upon the particular record and the form it takes. This may include the addition of an electronic signature to the record to demonstrate checking or may take the form of an electronic or physical form completed to demonstrate an electronic record has been checked. Electronic records should where ever possible include an electronic record of any changes. Section 3 Food Safety and Quality Management System Clause 3.1.1 Do procedures all have to be documented? ‘Procedures’ are referenced frequently within the Standard. A procedure must be documented (refer to glossary). Clause 3.4.2 What training do internal auditors have to have completed and what does ‘independent from audited department’ mean? Internal auditors should be able to show via training records that they have received formal training either via attendance of an external course or via training within the company. Training should cover the planning and scheduling of internal audits, preparing reports and follow up of audit findings. The objective behind the requirement for auditors to be independent of the area being audited is to ensure that the audit is rigorous and thorough and is not influenced by the work which may need to be carried out to effect corrections and improvements. Auditors should not be biased or influenced. F039 Issue 3 Released 4/11/2013 Issue 6 FAQ’s Page6 of 18 External auditors may need to be used where there are insufficient internal resources . Clause 3.4.5.2 Filtration of compressed air – can the filter be anywhere in the compressed air system and what size filter is expected? The objective of the filter is to prevent dust particles and lubricating oil from the compression system from contaminating the products. The best position and size of the filter may vary depending on the position of the compressor and lay out of the compressed air system and the source of the air used. The site should be able to justify the effectiveness of the filtration system employed Clause 3.5.3 How do you manage outsourced activities e.g. cleaning – what records would you expect to see? The performance of the supplier should be formally reviewed at a frequency appropriate to the service. In the case of an out sourced cleaning service the standards of cleaning would be expected to be assessed as part of the audit process (3.4.4) and records maintained of feedback on performance to the cleaning company – for instance a report book is often used. Other services such as Pest control, laundry services may be reviewed with the supplier on a 6 monthly or annual basis and a record kept of the review for instance minutes of such a meeting. Clause 3.5.4.1: …”declaration to brand owner of outsourced processes.” – is this only for retail branded products or for particular markets e.g. the UK? No this requirement applies to any product manufactured on behalf of a customer. The standard isn’t applied differently for different markets or different customers. Clause 3.9.2 How accurate does the quantity check / mass balance on traceability need to be? It is unlikely that the mass balance check will be able to account for all materials to an accuracy of 100%; however, the company needs to justify the discrepancies and demonstrate they understand the nature of the variance through dehydration of fresh ingredients, typical wastage on equipment and portion variances for example. The principle of this requirement is to ensure that the traceability system is effective and mass balance is a key measure of this workability and highlights areas for improvement. Clause 3.10 Would I be expected to do root cause, trend analysis etc. for complaints that are caused by customer abuse? F039 Issue 3 Released 4/11/2013 Issue 6 FAQ’s Page7 of 18 If there were the same repeated complaints being received then a root cause analysis should be undertaken to see if there is an issue with the packaging instructions for the product which may be leading to customer abuse. A change in this may reduce complaints. Section 4 Site Standards Clause 4.2.3 What is the “registration” that this clause requires? This clause relates to legal requirements to register premises with enforcement authorities pertinent to food safety and quality and includes as examples the requirement for food businesses to be registered with the local authority in the UK under Regulation (EC) No. 852/2004 on the Hygiene of Foodstuffs, Article 6(2) or that food premises in the USA must be registered with the US treasury under the 'Public Health Security and Bioterrorism Preparedness and Response Act of 2002'. It does NOT include other legal registrations related to personnel health and safety such as fire regulations or employment law as this is outside the scope of the Standard . Clause 4.3.1 Why is an area containing cooked meats not always considered to be a high risk area? High Risk areas contain only components/foods which have undergone a cook or similar process to achieve a 6 log reduction of Listeria. Where a single area has by necessity to include some components which have received a lesser kill as well as fully cooked components for instance a sandwich preparation area this will be classed as a high care area. Clause 4.3.1 How should the production zone categories be interpreted for products which meet the product characteristics for high care but are fully enclosed for instance within enclosed packaging equipment until filled and sealed e.g. dairies filling milk into cartons. In such circumstances the production area would be considered as an enclosed product area although additional precautions would be required when breaking into the lines or filler for maintenance. Where ever equipment is entered for instance to free product jams, cleaning etc. the necessary hygiene requirements to ensure the safety of the products must be completed before recommencing packing. Clause 4.3.1 If mayonnaise is produced in the same area as ready meals does the area become high risk or high care? It is necessary to ensure that where a range of products are produced that the appropriate risk area is applied to the particular product. This may identify a need for segregation between areas. Mayonnaise may be either high care or low risk depending upon the recipe and process most mayonnaise is ambient F039 Issue 3 Released 4/11/2013 Issue 6 FAQ’s Page8 of 18 stable and would be considered as low risk. Ready meals similarly may fall into low risk, high care or high risk depending on process given, cooking instructions and expected customer usage. Clause 4.3.5. What would be an acceptable alternative to a physical barrier between low risk and a high care operation? Would time separation be acceptable? Time separation would be an acceptable alternative in high care areas (but not high risk). The auditor must critically examine the arrangements for this to ensure that potential risks for contamination have been addressed and that the procedures for time segregation are consistently workable before accepting this solution. This must be described within the audit report. Clause 4.5.1 Can a company rely on the chemical analysis provided by the water authority or do they have to sub-contact the chemical analysis to an Accredited Laboratory. The type of chemical checks should be based on a risk assessment. For instance if as in the UK the water is supplied by a water authority an analysis from the authority would suffice unless there are other risks identified in the delivery system e.g. Lead pipes. Where water is extracted from bore holes and or sites have on site treatment facilities then additional checks will be required to ensure the water is not contaminated either at the bore hole or in treatment. Clause 4.6.2 Requires equipment to be suitable for food contact where appropriate and meet legal requirements – I can’t obtain a certificate of conformity for machinery we’ve had on site for years, what can I do? The requirement is designed to ensure that manufacturers are complying with relevant legislation, for example the EU ‘Materials and articles intended to come into contact with food Regulation 1935/2004’ and that such materials do not constitute a hazard to food. General principles should be to use approved suppliers known to supply products designed for food use. All new food contact equipment should be purchased with a certificate of conformity or specification detailing its suitability for food use; this may also be confirmed by a symbol or label on the product. Where this evidence is not available, then a risk assessment should be carried out to justify its use and determine that it is not a food safety risk. The risk assessment should consider factors such as, the nature of the food contact surface material and its known characteristics e.g. stainless steel is known to be a food grade material; length of contact time with the food and the nature of the food and its potential for contamination e.g. fatty foods may be more at risk from migration of contaminants from a plastic container for example. Further clarification should be sought e.g. from equipment manufacturer or testing such as migration tests where required. F039 Issue 3 Released 4/11/2013 Issue 6 FAQ’s Page9 of 18 Clause 4.8.4 What would be acceptable arrangements for changing facilities for High care operations? The objective of the clause is to ensure that protective clothing once applied is not contaminated particularly by pathogens before entry into the high care area. Time segregation i.e. a shared changing facility with low risk staff but with different shift start patterns would be acceptable. It may be necessary for the changing facilities to be cleaned between different groups of workers depending on risk. The auditor must be satisfied that the potential risks have been assessed and procedures are capable of being consistently operated without abuse. Clause 4.8.5 Are boot wash facilities acceptable on entrance to High risk areas? High risk areas need a higher level of environmental control than in high care areas due to the nature of the products handled. The use of clean footwear worn only in the high risk area and effective measures for changing into such footwear is the preferred option to meet the requirements of the Standard. The use of boot wash facilities at the entrance to a high risk area will be acceptable where this is managed and validated to effectively prevent the introduction of pathogens. The site shall have undertaken a risk assessment to identify the suitability of the boot wash facilities and controls to manage the effective sanitation of footwear. The controls shall have been validated by microbiological swabbing of footwear and the floors and drains in the high risk area, to demonstrate the absence of Listeria species. For such controls to be effective it would be expected that this includes the following: The footwear shall be company issued and of a design which is easily cleaned i.e. smooth upper surfaces, cleats on soles shall be sufficiently spaced so as not to trap dirt which may not easily be removed by boot wash equipment. Consideration of the potential for gross contamination of boots prior to boot washing i.e. the footwear shall not be worn outside of the facility or in low risk processing areas prior to entering the high risk area. The boot wash equipment shall be suitably designed, well maintained and demonstrably effective to clean and sanitise the foot wear. F042 Issue 1 BRC Global Standard for Food Safety Issue 6 Position Statements Released 8/5/2012 Page5 The minimum cleaning time and levels of detergent and sanitiser used shall be determined, documented and controlled to ensure effective cleaning of footwear. Records shall be maintained of detergent/sanitiser checks, and effectiveness of cleaning of the boot wash facilities. F039 Issue 3 Released 4/11/2013 Issue 6 FAQ’s Page10 of 18 Clause 4.8.6 dictates the requirements for hand washing facilities to be used before entering production. Does this mean that roller towels can’t be used? This requirements clearly specifies what can and can’t be used and includes that roller towels cannot be used at hand washing stations in production areas as they are not ‘single use’; they can however, be used in toilets but only if they are not the only facilities provided before re-entering production. Clause 4.8.6 Is there a relaxation of the requirement for hand cleaning facilities in low risk factories for example flour mills, breweries, produce pack houses. There remains a requirement for providing hand cleaning facilities to enable employees to wash their hands before entry to production areas (note this may be in a changing or toilet area). The use of gel sanitisers alone does not provide a suitable alternative as this does not clean the hands but provides only a partial sanitising effect. Clause 4.9.3.4.3: …”records shall be maintained of all container breakages….” High speed filling lines in the wine/beverage industry often incorporate automatic clean cycles following a breakage in the filler but no records are kept. What does the standard expect in such situations? In such circumstances the site must be able to demonstrate that the automatic process they have established is effective in preventing the potential spread of glass to other open containers, effectively removes all glass during the wash phase and separates effectively at risk product for disposal. Where this can be shown to be effective then routine monitoring of the filler for glass and an effective process to hold any suspect product could be accepted. The procedure must be verified on a regular basis Clause 4.10.3.1 Metal Detection would a low or zero number of customer complaints be justification for not having a metal detector? Do different rules apply when packing branded or customer label products? Whilst complaint levels is a factor in making a decision on the necessity for metal detection this alone will not be taken as justification that a metal detector is not required – not least because it is well known that many contamination issues go un reported by customers. Any justification for the absence of metal detection should be based on the nature of the product, risk to the consumer and alternative controls in place at the site which prevent metal contamination. So for example metal in a meat pie or sausage would probably only be detected when the product is in the mouth where as a piece of metal in a bag of potatoes would hopefully be found before consumptionpresenting a low customer risk. The meat pie would be expected to be metal detected. F039 Issue 3 Released 4/11/2013 Issue 6 FAQ’s Page11 of 18 It is important to recognise that the requirements of the standard apply irrespective of whether the products are branded or retailer own label the standard applies to the food safety and quality systems at the site. The BRC Certificate demonstrates a minimum level of food safety at the site and must be consistently applied to all products within the audit scope. Please see the decision tree shown in the Issue 6 Position Statements document for further information. Clause 4.10.3.3 This requests “a belt stop system with an alarm where the product cannot be automatically rejected e.g. very large packs”. Are there other instances where stop belt systems would be acceptable? Other examples could include delicate products where the use of a belt stop system is necessary to prevent damage to the finished product e.g. quiches, gala pies, freshly topped decorated pies, decorated celebration cakes, chocolate gateaux etc. The BRC have produced a Position Statement (reference F042) relating to the acceptability of metal detectors. Section 5 Product Control Clause 5.2 I handle nuts on my site, but add a statement on my packaging stating ‘it cannot be guaranteed that this product is free of nut traces’ – do I have to comply with any of the requirements of section 5.2? Yes, you still have to carry out a risk assessment and consider what steps are appropriate for your company to minimise the potential for cross contamination. Clause 5.2 I do not handle any allergen containing materials on my site and am not making any ‘nut free’ claims, are the clauses of 5.2 applicable? The following clauses would still be applicable 5.2.1.and 5.2.9 Clause 5.3 Do the requirements of this section apply to mandatory legal claims such as country of origin labelling? Yes- where ever information such as country of origin is marked on a product the manufacturer must be able to demonstrate that this is correct and this section sets requirements to be met to achieve this. Clause 5.3.2 Mass Balance for product claims. Is it necessary to carry out a mass balance test on every product where a claim is made? F039 Issue 3 Released 4/11/2013 Issue 6 FAQ’s Page12 of 18 The objective of the mass balance traceability is both to demonstrate that sufficient detailed records are maintained to allow an accurate mass balance test to be carried out at any time with any particular process and secondly to check that errors/mixing of products has not occurred i.e. the claim is valid. The test shall be carried out at least once every 6 months however where applicable products are produced using very different processes it may be necessary to check more regularly to ensure that each production process is controlled. It will not be necessary to check each individual product every 6 months unless this is a requirement of the particular scheme associated with the claim. The test should as a minimum take a batch of incoming raw material (for which the claim relates e.g. Aberdeen Angus Beef ) and identify where all of this batch was used, this may include wastage and remaining stock if appropriate. The test should be able to account for the use of all of a batch of materials. Section 6 Process Control Clause 6.1.1. Do I have to emphasise “milk” in recipes if all I make is cheese and all the recipes contain milk? No If an allergen is used in all products manufactured at a factory there would be no absolute requirement to emphasise this on the recipe, however should the product range change this would be required. Clause 6.1.4 Is it a requirement to undertake temperature distribution studies in cold stores and freezers? For small freezers the temperature goes up and down on defrost and whilst filling and emptying. The objective is to ensure that products can be consistently stored within the temperature ranges specified and are therefore not at risk of spoilage within shelf life. The level of risk will depend upon the product, time spent in storage and margin allowed by the temperature settings of the store. Temperature distribution studies would not be necessary for small chill or cold stores where product is stored only for short periods. Section 7 Personnel Clause 7.2.1 Is the wearing of wedding bands including “Rhukhi” friendship bands (Hindu/Siekh) acceptable? Where such jewellery cannot be effectively cleaned or may present a risk of contamination this must either be removed or covered. F039 Issue 3 Released 4/11/2013 Issue 6 FAQ’s Page13 of 18 Clause 7.2.2: Requires hand cleaning to be performed on entry to the production area. Does this apply in enclosed product areas? Yes as this is good practice for the food industry Clause 7.4: 2 Protective clothing has changed from Issue 5 with the removal of the wording “based on a risk assessment” how does an industry now justify that they do not have protective clothing in the true definition of clothing that is worn to protect the product from possible contamination from the person. But rather clothing/uniforms that are worn to protect personal clothing from getting dirty. The standard now states ‘suitable’ so instead of risk assessing the site must define what is suitable for that process. Protective clothing but not necessarily head coverings would be expected to be supplied to employees working in enclosed product areas as for instance in a winery. Clause 7.4. Does the company need to supply protective clothing to contractors performing construction or maintenance work in their facility? Or….do they need to ensure that they are wearing protective clothing that is appropriate to the area? The intention of the clause is to ensure adequate protection for products. The level of controls will depend upon the product risk zone and extent of work undertaken. Building as in construction work should be screened from production areas and builders should not enter the active production area whilst production is in process. In low risk open product areas the company may supply protective clothing for sub-contractors or where provided by the contractor this needs to comply with site requirements. Generally speaking we would not expect sub contract engineers to be working in high care or high risk areas during production periods. Where this is necessary the subcontractors shall be supplied with the company issued protective clothing and follow the site changing procedures before entering the area in order to protect the products. Clause 7.4.2 Are head coverings required in enclosed product areas e.g. wine bottling, breweries? The standard requires that protective clothing is available that fully contains scalp hair to prevent contamination – Where the product and packaging is fully protected from the risk of contamination for instance enclosed product areas head coverings would not be an absolute requirement. It should be noted that whenever equipment is opened or lines broken into the staff concerned must wear protective clothing and head coverings. F039 Issue 3 Released 4/11/2013 Issue 6 FAQ’s Page14 of 18 Clause 7.4.4 What would be an acceptable certification for Laundries? There are a range of certification standards for Laundries operating in different parts of the world. Where a certification scheme is used the site must be able to demonstrate to the auditor that the scheme fulfils the requirements of 7.4.4 Unannounced audit schemes Please see the full unannounced audit guide for more details on this scheme. Enrolment Scheme How does the weighting work for the Enrolment scoring system? The weighting will be based on the severity of the non-conformity i.e. Critical, Major, Minor and how the clause relates to the 3 levels in the GFSI Global Markets Capacity Building Programme. GFSI have a programme which identifies particular requirements for Basic Level and Intermediate level compliance as stepping stones to achieving eventual certification against a GFSI benchmarked scheme such as BRC. The requirements within BRC Issue 6 have been matched to the requirements at the different levels within the GFSI programme. Failure against BRC requirements equivalent to GFSI Basic level will be more heavily weighted than failure against equivalent Intermediate level requirements. Does BRC provide a scoring system to calculate the score for auditors? Yes the BRC will be issuing a spread sheet to automatically calculate the Enrolment scores. Is there be a separate audit report template for enrolment. Yes. The report format will be visually distinct to prevent confusion between enrolment and certificated audit reports. The contents of the reports will be identical except that the audit result section is based on a total score and score per section. The non- conformance reporting section will be slightly different to allow for an action plan where correction cannot be achieved within 28 days. Our site was not certificated and received the enrolment audit report. How soon can I undertake a new audit? F039 Issue 3 Released 4/11/2013 Issue 6 FAQ’s Page15 of 18 The sites in the Enrolment program are likely to have a significant amount of work to do to ensure non conformities identified have been effectively addressed before commissioning the new audit. Due to the nature and number of non-conformities, it is unlikely that these nonconformities can be addressed and fully effective improvements implemented and established within a 28 day period; although there may be some exceptions. It is likely; therefore, that in most cases the re-audit will take place after the 28 day period and typically a 3 month period may be required to fully establish new systems or patterns of working. Auditing the Standard Why are the BRC now insisting on more of the audit time being spent in the factory? Concerns have been expressed that not enough time is spent in production and too much time spent reviewing paperwork in the office. Users of the Standard for supplier approval are rightly concerned to ensure that emphasis is given to the factory environment; product and food safety controls in production and working practices since these directly affect the safety and quality of the food being produced. It is expected that at least 50% of the audit is spent in the production and ancillary areas. This should include assessing the production process, observing activities, interviewing staff in production, reviewing relevant procedures/work instructions recording forms within the production area. These are all things that good auditors will already have been doing and need to be adopted by all. When calculating the audit time in the factory what does this include? Whilst most of the time allocated to the factory (GMP) audit is expected to be spent within the processing areas of the factory the inspection of ancillary areas including storage facilities, exterior areas, engineering facilities, transport, canteen and staff facilities are also included when calculating the total time in the factory. The audit report shall show an estimate of the time spent auditing the factory. What is expected by the BRC of auditors when opening equipment to inspect cleaning? To ensure that the standards of cleaning are properly challenged it is expected that some equipment should be opened for instance by removing panels or dismantled to check that cleaning is more than superficial. Sites need to know in advance e.g. at the opening meeting that this will be part of the site audit and any necessary arrangements should be made for engineers to be present. It is NOT expected that lines will be stopped for inspection. The audit should be limited to lines or equipment not in production at the time of the factory tour or the inspection of equipment outside of production periods. F039 Issue 3 Released 4/11/2013 Issue 6 FAQ’s Page16 of 18 Auditors must at all times be aware of and obey health and safety rules at the sites. How does the BRC expect the traceability (vertical audit) to be undertaken? BRC expect a traceability check (vertical audit) to be carried out on a product selected by the auditor. This is in addition to the review of the method of achieving traceability which forms part of the GMP audit. The exercise shall be based on a product selected by the auditor the product shall have been produced typically in a 2-5 months period prior to the audit date. Where a claim is made about a component of the product (as per 5.3) the test shall include a mass balance of the material subject to the claim. The mass balance test should be in both directions (finished product to raw material and vice versa). BRC suggest the vertical audit (i.e. traceability documentation plus all associated production and raw material documentation) should be carried out only as part of the trace backwards from finished product to raw materials. To undertake such an exercise in both directions would be too time consuming unless issues are suspected. Where the site produces products which make a claim of provenance (5.3) the product selected for the traceability study should be a product for which such a claim is made. Details should be captured in the auditor’s checklist and summarised in the final audit report. What is expected of auditors when carrying out line start up or Pre operation checks? Where ever possible auditors should arrange to carry out an inspection of lines before the start of production. Typically this would be accompanied by the person who normally undertakes this check for the site being inspected. The objective is both to ensure the standards of cleaning are good enough and assess how the site undertakes such a check and the standards the site its self expects. There will be some production processes where such checks are impossible for instance continuous processes or where timing is such that this would be impractical. The auditor’s notes should indicate where a check has been completed and if not why not. What are the BRC’s expectations when examining records during the documentation review? It is important that when examining records this is a fair but true test of the sites records and procedures. It is expected that the auditor shall manage the F039 Issue 3 Released 4/11/2013 Issue 6 FAQ’s Page17 of 18 selection or records to demonstrate compliance. The factory inspection shall be used by the auditor to identify actual records to be examined during the documentation audit. This could include Employee names for – training record review Reference numbers of measuring equipment – for review of calibration records Examples of glass/plastic items to check against the glass register Can non-conformities be issued against Statements of intent (SOI)? Yes and these can be minor, major or critical Statements of intent summarise the overall objectives and the clausal requirements below show how these can be achieved through policies and procedures e.g. customer complaints (3.10) – the intent is that complaints are reduced. It maybe that the company meets all the individual requirements by having procedures for recording and investigating but complaints may still be increasing – therefore the intent is not met. In this case a non-conformity could be raised against the statement of intent. I have had a BRC audit and am not happy with the non-conformities identified or the grade awarded – what can I do? The company has the right to appeal the certification decision made by the certification body which should be made in writing to the certification body within 7 days of the decision. The certification body shall give a full written response within 30 days following a full and thorough investigation. The company also has the option to contact the BRC if resolution cannot be attained by the two parties. F039 Issue 3 Released 4/11/2013 Issue 6 FAQ’s Page18 of 18