Capital Cost Estimating Q&A

advertisement

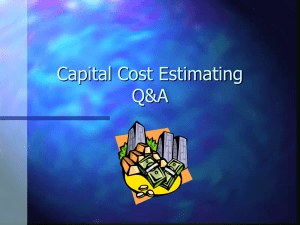

Capital Cost Estimating Q&A Today Suggest you review Equipment Costing Folder on CD Is this real? What do we do? How does it work? Methods of estimating Using CapCost What is a “Capital Cost?” ‘Dealing’ with CapCost limitations Is This Real ? Question: We seem to be applying simplifications and assumptions that this project doesn’t seem very ‘real.’ Your thoughts? Question 1: What do we do? We will use CapCost which integrates Estimation of equipment costs Utility costs Raw material costs and product revenue Other costs Profitability analysis Sensitivity analysis CapCost See the material in the CapCost folder Install the program from the CD that came with the text (run install.html) View the movies on the CD (run cost.html) with a computer that has speakers and Quicktime (at home or use the TEAM computer) Run Capcost.xls and look through it How Does It Work? Equipment Purchase Price Equipment Factors “Off Sites” Cost Direct Field Labour (DFL) 0.25 x DFC Direct Field Cost (DFC) x Factors 1.0 to 1.6 x DFL Indirect Field Cost (IFC) Home Office Engineering Allowances Total Project Cost (ITC) Estimate •DIRECT FIELD COSTS •Equipment Cost •bulk materials (piping, valves, instruments) & labour to install •off-sites (pipe racks, rail spurs …) •INDIRECT FIELD COSTS •engineering, freight, insurance, overhead, const supervision •CONTINGENCY AND FEES •first fill of plant, taxes, duties •escalation TOTAL PROJECT (CAPITAL) COST Method 1: Lang Factored Estimate Total Capital Cost = Flang * (Sum Of Purchased Cost of Equipment) Flang = 4.74 for fluid processing plant Method 2: The CapCost Approach Equipment Parameters (Pressure, MOC, Size, Hp …) “Base Cost” = Purchase Cost of Equipment - in Carbon Steel and 0 barg Bare Module Factor = f (Factorpressure, Factormaterial) BARE MODULE COST (Directs and Indirects) Which One Do We Want? - installed equipment in actual materials and actual pressure Module Factor = 1.18 MODULE COST OF PLANT - for expansion to an existing Plant -contingency 15%, fees 3% Grass Roots Factor = 1.30 GRASS ROOTS COST OF PLANT - infrastruction (utilities, off-sites aux. Buildings, product storage, loading and unloading facilities ...) CHEE 470 Stops Here Determine Equipment Cost Note: Price for Carbon Steel Construction and 0 Bar(g) Fixed Tube exch with 28 m2 = $6500 Convert To Today’s $’s using the CEPCI value Factor to Today’s Cost $6500 * (1999 CECPI / 1996 CECPI) = today’s cost $6500 x (390.6 / 381.7) = $6650 in 1999 Pressure Factor (Fp) Pressure Factor Fp = 1.14 Material Factor (Fm) Bare Module Factor FBM Cost of Equipment Installed Fp Fm 1.14 x 3 = 3.42 Therefore FBM = 7 Bare Module Cost = Base Cost x FBM = $6650 x 7 = $46,550 “Module Cost” Of Plant Add Contingency and Fees (building permits, environmental permits etc.) Module Cost = 1.18 for all equipment) S (of Bare Module Cost Module Cost = 1.18 x $46,550 = $ 54,900 Now a Short Demo A movie to illustrate the capital cost sections of CapCost One of the sheets in an Excel workbook The utilities, raw materials and cash flow sections will be covered later in the Economic Analysis workshop Questions What do we do when equipment is larger than CapCost can cost? Split it up into equal sized pieces Get a cost in CapCost and then apply the capacity factor exponent new cost=old cost x capacity ratio0.6 Special Equipment CapCost has an equipment type “User Defined” If you know the cost of something, you can supply A name Equipment cost Bare Module Cost Set the first factor to 1, ignore the second User Defined Equipment Question What is a capital cost? Capital Cost What’s “Capital ?” Capital is the money required to build a plant or facility It’s separated from “Expense” money because of the Tax implications imposed by Revenue Canada, IRS, etc. Facility Timeline Facility Creation Conceptual Engineering Expense $ Detailed Engineering & Construction Capital $ Capital Cost Facility Operation Start-up Expense $ Expense $ - Operating Expenses -Depreciation Capital vs Expense Once the plant is running ‘Expenses’ are small items or costs which are incurred yearly, or have about a 1 year life. i.e. Software, Office supplies, wages, advertising, heat, lighting, ... When Calculating Yearly Income Subtract your Expenses From Your Income Capital vs Expense ‘Capital’ are expensive items or items which have more than a year of life. i.e. House, lawnmower, TV, computer, chemical plant equip, first fill of chemicals Revenue Canada etc. only allow you to subtract a % of the Capital every year to account for the wearing out of the facility (depreciation). This is called the “Capital Cost Allowance” Capital vs Expense Capital Cost Allowance ( CCA ) Works Like a Bank Account Revenue Canada allow a % of the remaining asset value to be claimed Remaining Asset Value Time (years) CCA Classes Capital vs Expense Revenue Canada Treat Depreciation per above More common (?) to treat Depreciation with a straight line for the economic analysis 10 year depreciation, therefore 10% of capital is ‘expensed’ per year Taxable Income Income That’s Taxable (Net Income) Taxable Income = Income - Expenses - CCA Can’t use CCA if Expenses are greater than Income (can’t use CCA to claim a loss) CCA can be ‘banked’ for later years where profit is occurring Small Business Tax- Revenue Small Business Tax - Expenses CCA Capital - The Point Capital is only allowed to be ‘depreciated’ over years and thus it’s ability to minimize taxable income is limited. Expenses are claimed in the year they’re paid. They’re better for minimizing your taxes. The Games People play The Capital Cost Estimate The tax implications of Capital money requires that you know how much Capital was spent on any asset. The business financial analysis (NPV etc.) requires that you know the Capital Cost and the Operating Cost well ahead of actually spending any significant amounts of money. Capital Cost Estimate Summary: The cost to initially build the facility which will be depreciated over time. Question: CapCost - arrggh! CapCost does not change price when we change the maximum pressure. What’s wrong? Off The Shelf Items Piping, Valves, Pumps and most equipment have been standarized in design pressures of the connecting Flange Standards are called 150, 300, 600, 900, 1500, 2500 “lb” flange ratings. A 150lb rating 150 psig rating, temperature is important in the ultimate strength of the item Along with standard flanges are standard pipe wall thickness (Sch 40, Sch 80 etc.) Flange Rating Max Pressure vs Temp 1600 Pressure (psig) 1400 1200 150 lb Rating 1000 300 lb Rating 800 600 lb Rating 600 300 lb 304 SS 400 600 lb 304 SS 200 0 0 500 Temp (°F) 1000 Heat Exchanger Standards TEMA - Tubular Exchanger Manufacturers Association dictates minimum requirements for exchanger mechanical design Legislation does not require TEMA standards be used. ASME- Pressure Vessel Standards ASME Code It started in Chicago after a major explosion in a shoe factory that had a boiler. The boiler explosion caused the government to start regulating pressure vessels (including boilers). A tool for regulating manufacturers of pressure vessels, heating exchangers, and piping, not pumps, not compressors (no rotating equipment) ASME- Pressure Vessel Standards Since the explosion in Chicago codes were developed for the guidance in the calculation of pressure vessels, tables of metal strength vs temp Safety factor of 4 has historically been applied to the mechanical strength of metal, recently (year 2000) it was reduced to 3.5 ASME Code Sections I - Power Boilers II - Materials (properties i.e. allowable stresses) III - Nuclear Power Plants IV - Heating Boilers V - Non Destructive Examination VII - Guidelines for the Care and Operation of Heating Boilers IX - Welding and Brazing Qualifications X - Fiber-Reinforced Plastic Pressure Vessels XI - Rules for Inservice Inspection of Nuclear Power Plant Components Minimum Design and CapCost Allowing CapCost to choose a minimum makes sense since the manufacturer would do the same. The Final Screen