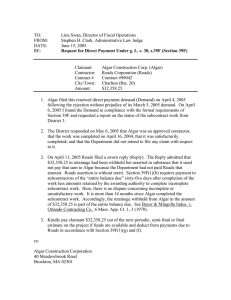

Canadian-Heavy-Oil-Association-11.10.2011

advertisement

Canadian Heavy Oil Association Presentation November 10th, 2011 A Different View of Project Execution SAGD Construction Project Timelines Background in SAGD Deer Creek Energy - Joslyn Pilot Plant Background in SAGD Deer Creek Energy - Joslyn Commercial Facility Background in SAGD Connacher Oil and Gas – Pod I Commercial Facility Background in SAGD Connacher Oil and Gas – Algar Commercial Facility Current Projects Pengrowth Energy Corporation – Lindbergh Pilot Plant • Currently Under Construction • Scheduled for Startup in Q1 of 2012 Southern Pacific Resources – McKay River Commercial SAGD • Currently Under Construction • Scheduled for Startup in Q2 of 2012 N-Solv Corporation – McKay River Pilot Project • Currently undergoing Engineering • Scheduled for Startup in Q4 of 2012 Typical Project Algar Commercial Facility – Early Road Construction Typical Project Algar Commercial Facility – Road Construction Complete Typical Project Algar Commercial Facility – Plantsite Civil Preparation Typical Project Algar Commercial Facility – Pile Driving Typical Project Algar Commercial Facility – Day 30 Typical Project Algar Commercial Facility – Day 150 – Evaporator Lift Typical Project Algar Commercial Facility – Typical Module Installation Typical Project Algar Commercial Facility – Day 240 Typical Project Algar Commercial Facility – First Steam Project Execution Process Design • Detailed Process Review • Early Involvement of Operations • Ability of the Team to quickly evaluate process options incorporating input from all stakeholders & to implement decisions rapidly • Ability of the Team to recognize unit operations that have been successfully utilized in similar applications and not waste time in re-evaluation unless justified Contracting Strategy & Risk Management • Best scenario for a successful project is where the goals of the Owner, Project Managers, Vendors, and Contractors are all aligned. • Lump Sum for Engineering Contractor based on a % of +/- AFE • Sole Source Supply where justified • Detailed bid process where justified • Time and materials based contracts • Field contracts a mix of fixed price and hourly Project Execution Shop Fabrication Procurement • Onus heavily on Engineering Contractor • Schedule of IFC drawings determines the project schedule and predicted cash burn • Management of Change • Attention to detail & very rigorous shop inspection • Constructability Logistics and Transport •Difficulty of the Transportation Corridor •Close communication between Shop Coordinators, Field Supervisors, and Transport Contractor •$/km contract for transport •Flexibility of field contracting strategy Project Execution Field Construction • Under this execution strategy this area presents the greatest risk for cost control • Success is highly dependent on accuracy of engineering contractor – stuff has to fit • Primary Mechanical Contractor on hourly • Secondary Mechancial Contractor on hourly • Typical to go lump sum of E&I • Flexibility for Field Supervisors • System in place to closely monitor Cash Burn vs Productivity. Specific Techniques Tight Spooling Specific Techniques Pipe Modules Specific Techniques Pouring Pod I Tank Base Specific Techniques Algar - Pile Supported Steel Tank Floors Specific Techniques Pod I Grade Beam, Floor, Supports, & Mod Installation Specific Techniques Algar Grade Beam / Piles Specific Techniques Algar Equipment Setting Closing Remarks “It’s about the People, not the process” Neal Gartner, Engineering Manager, AMEC BDR October 2011