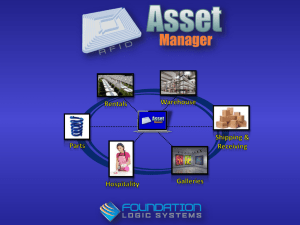

Management Reporting - Foundation Logic Systems

advertisement

RFID Linen Management System Presented By: In the Hospitality Industry for Eighteen Years Offices in Los Angeles, Miami, New York and Australia RFID Installations for Eight Years Programming Staff and Network Specialists Experienced Installation Team 24/7 Support with a 15 Minute Response Time Evolution in Asset Tracking It started with barcode technology, enabling individual tracking Then, RFID tags enabled tracking for garments and linens Foundation LogicSystems now offers UHF RFID tags for tracking every asset with the ability to read twenty feet away Finally! Linen and Terry Can Be Tracked How? By attaching RFID tags to every piece Via scanning every linen to the laundry and back Doing so makes taking inventory easy and accurate And, gives a return on investment in less than one year! UHF RFID Tags Tags can survive harsh industrial laundry process RFID tags can be washed 200 times and are reusable Thin and flexible linen tag with a 4 -6 foot read range The tags perform at a 99.9% accuracy rate! Linen Tracking RFID Tags Are Placed in a Label and Sewn on Terry , Linen and Garments Each Asset is Identified by Vendor, Item #, Description, Cost and Depreciation Method Setting up the System The ID #, Location, Current Value and Length of Time in Service is Identified Linen Information The RFID Scanning Process Antennas send the info the reader 800 Linens The reader converts the signal The antenna captures the RFID tag numbers sewn on the linens The computer reads the data. Up to 800 items can be read at once with 99.9 % accuracy When Linens Arrive on Property an Immediate Inventory is Available Report Module Soiled Linens Laundry All Soiled Linens are Scanned at One Time When Sent to the Laundry Hamper Reading Station Antennas can be Placed in Doorways or Loading Docks When Linen, Terry & Garments are Sent to Laundry – Quantities are Verified Cleaned Linens Received at the Hotel All Items in the Hamper are Scanned at Once and Produce an Outstanding Report Outstanding Report Linen Closet Reports Provide Stocking Requirements for Every Floor Stocking Linen Closets Laundry Billing Reports are Produced as Items are Received at the Hotel Laundry Billing Report Departmental Cleaning Reports are Expensed by the Rooms and F&B Departments Expense Reports Real-Time Inventory A Hand-held Scanner Can Take Inventory in a Linen Closet in Minutes and in Real-Time Hundreds of Items can be Read at Once - Counting and Labor-Intensive Monthly Inventories are Eliminated Inventory Module Establish Loss Control Antennas can be Placed at Employee Exits to Monitor Assets Leaving the Property A Purchase Requisition can be Automatically Created Based on Required Purchases Purchasing Module The System Enables Creation of Purchase Orders and On-Line Approvals Purchasing Module A Report Specifying the Age of Every Linen can be Created Management Reporting Using One Report, Management can Determine if the Linen Department has an Optimum Inventory Management Control Linen Manager --- Saves You Money in Four Primary Ways Holding the Laundry Accountable You'll know exactly what is sent to the laundry and what is returned Reduction in Purchasing Savings made by keeping the inventory at optimal levels, and not purchasing more linen than you needed Vendor Accountability The life cycle of linen can be tracked and vendor representation monitored Labor Reduction Savings through RFID automation of linen inventory and accounting tasks Labor 37% Purchasing 12% ROI Losses 51%