Large scale manufacturing technology for high-performance

lightweight 3D multifunctional composites

Abstract

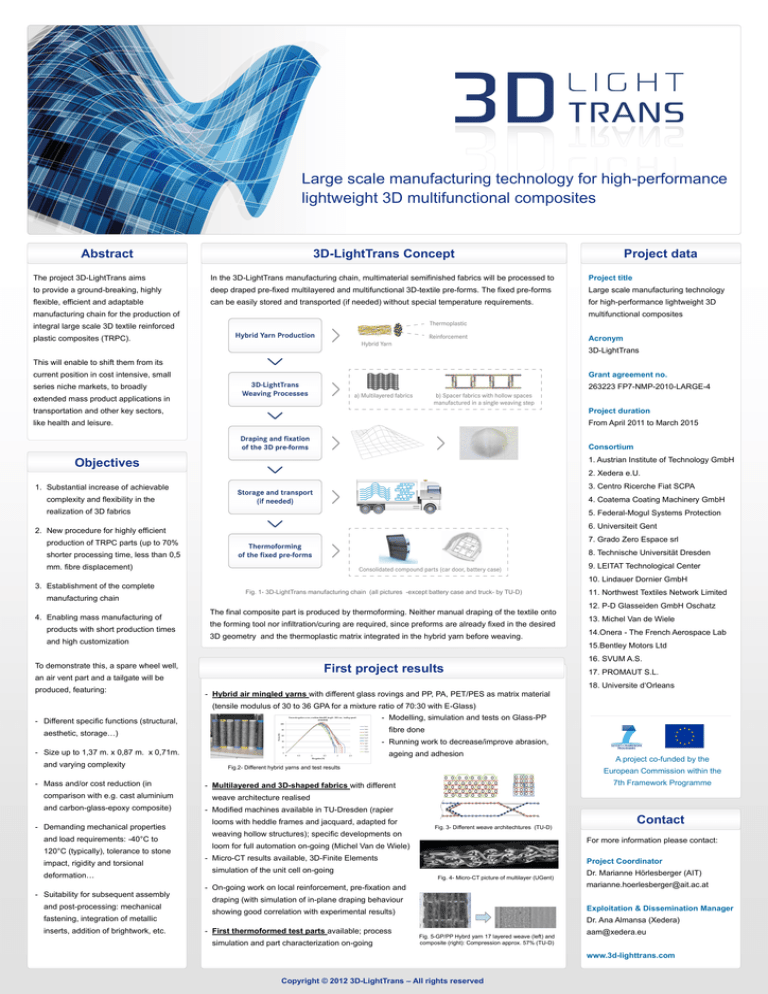

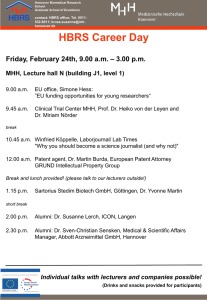

3D-LightTrans Concept

Project data

The project 3D-LightTrans aims

In the 3D-LightTrans manufacturing chain, multimaterial semifinished fabrics will be processed to

Project title

to provide a ground-breaking, highly

deep draped pre-fixed multilayered and multifunctional 3D-textile pre-forms. The fixed pre-forms

Large scale manufacturing technology

flexible, efficient and adaptable

can be easily stored and transported (if needed) without special temperature requirements.

for high-performance lightweight 3D

manufacturing chain for the production of

multifunctional composites

integral large scale 3D textile reinforced

plastic composites (TRPC).

Acronym

3D-LightTrans

This will enable to shift them from its

current position in cost intensive, small

Grant agreement no.

series niche markets, to broadly

263223 FP7-NMP-2010-LARGE-4

extended mass product applications in

transportation and other key sectors,

Project duration

like health and leisure.

From April 2011 to March 2015

Consortium

1. Austrian Institute of Technology GmbH

Objectives

2. Xedera e.U.

3. Centro Ricerche Fiat SCPA

1. Substantial increase of achievable

complexity and flexibility in the

4. Coatema Coating Machinery GmbH

realization of 3D fabrics

5. Federal-Mogul Systems Protection

6. Universiteit Gent

2. New procedure for highly efficient

production of TRPC parts (up to 70%

7. Grado Zero Espace srl

shorter processing time, less than 0,5

8. Technische Universität Dresden

mm. fibre displacement)

9. LEITAT Technological Center

10. Lindauer Dornier GmbH

3. Establishment of the complete

Fig. 1- 3D-LightTrans manufacturing chain (all pictures -except battery case and truck- by TU-D)

manufacturing chain

4. Enabling mass manufacturing of

products with short production times

and high customization

The final composite part is produced by thermoforming. Neither manual draping of the textile onto

the forming tool nor infiltration/curing are required, since preforms are already fixed in the desired

3D geometry and the thermoplastic matrix integrated in the hybrid yarn before weaving.

11. Northwest Textiles Network Limited

12. P-D Glasseiden GmbH Oschatz

13. Michel Van de Wiele

14.Onera - The French Aerospace Lab

15.Bentley Motors Ltd

16. SVUM A.S.

To demonstrate this, a spare wheel well,

First project results

an air vent part and a tailgate will be

produced, featuring:

17. PROMAUT S.L.

18. Universite d‘Orleans

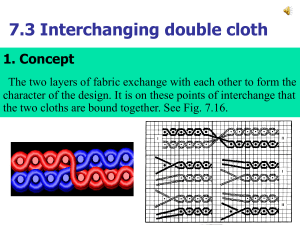

- Hybrid air mingled yarns with different glass rovings and PP, PA, PET/PES as matrix material

(tensile modulus of 30 to 36 GPA for a mixture ratio of 70:30 with E-Glass)

- Modelling, simulation and tests on Glass-PP

- Different specific functions (structural,

fibre done

aesthetic, storage…)

- Running work to decrease/improve abrasion,

- Size up to 1,37 m. x 0,87 m. x 0,71m.

and varying complexity

- Mass and/or cost reduction (in

comparison with e.g. cast aluminium

and carbon-glass-epoxy composite)

- Demanding mechanical properties

and load requirements: -40°C to

120°C (typically), tolerance to stone

impact, rigidity and torsional

deformation…

ageing and adhesion

Fig.2- Different hybrid yarns and test results

European Commission within the

7th Framework Programme

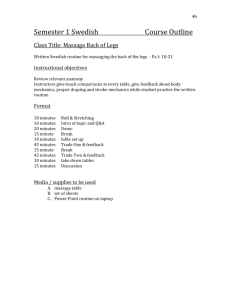

- Multilayered and 3D-shaped fabrics with different

weave architecture realised

- Modified machines available in TU-Dresden (rapier

looms with heddle frames and jacquard, adapted for

Fig. 3- Different weave architechtures (TU-D)

weaving hollow structures); specific developments on

and post-processing: mechanical

loom for full automation on-going (Michel Van de Wiele)

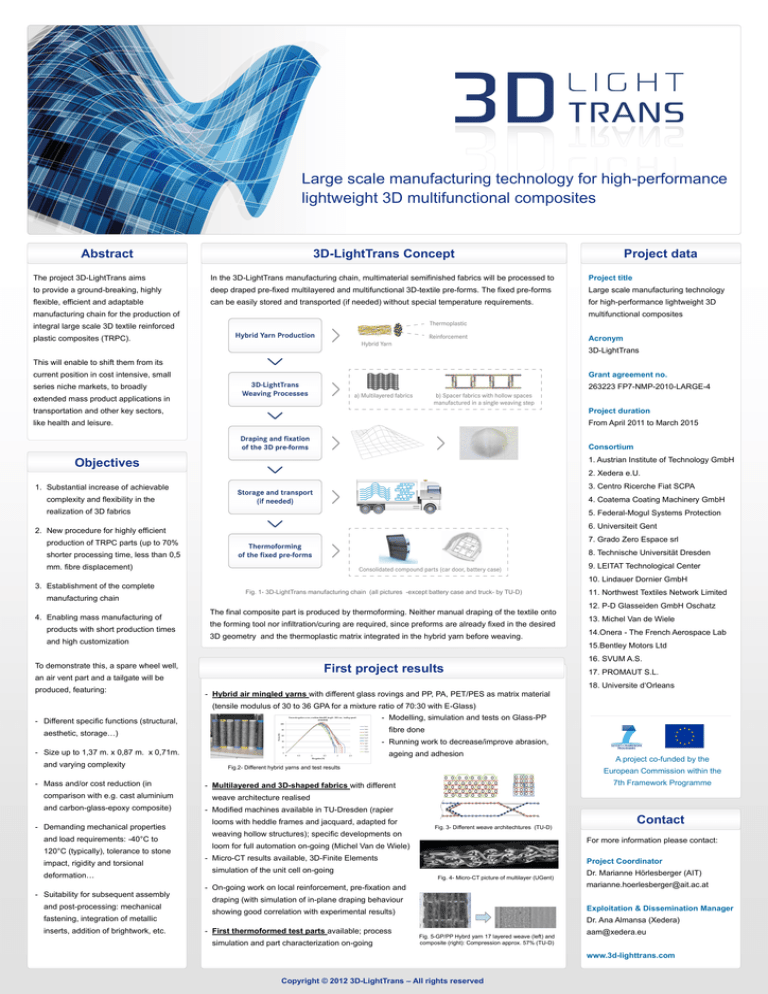

- Micro-CT results available, 3D-Finite Elements

Project Coordinator

simulation of the unit cell on-going

Fig. 4- Micro-CT picture of multilayer (UGent)

Dr. Marianne Hörlesberger (AIT)

marianne.hoerlesberger@ait.ac.at

draping (with simulation of in-plane draping behaviour

Exploitation & Dissemination Manager

showing good correlation with experimental results)

fastening, integration of metallic

inserts, addition of brightwork, etc.

Contact

For more information please contact:

- On-going work on local reinforcement, pre-fixation and

- Suitability for subsequent assembly

A project co-funded by the

Dr. Ana Almansa (Xedera)

- First thermoformed test parts available; process

simulation and part characterization on-going

Fig. 5-GP/PP Hybrd yarn 17 layered weave (left) and

composite (right): Compression approx. 57% (TU-D)

aam@xedera.eu

www.3d-lighttrans.com

Copyright © 2012 3D-LightTrans – All rights reserved