Condition assessment of water pipes

advertisement

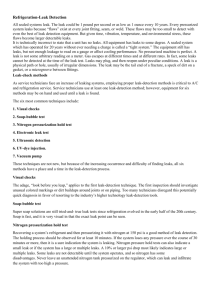

Transmission Main Leak Detection and Condition Assessment: Brazil Trade Mission 2012 Corporate Overview • Formed in 2003. • Based in Toronto. • Original focus was on correlation based Leak Detection Equipment, specifically for PVC. • Developed Non Destructive pipe condition assessment technology • Changed focus to service offerings: ▸ Leak detection for Large diameter mains ▸ Condition assessment for ferrous and asbestos cement mains 2 Agenda • • • • • • • Correlation Theory Review Echologics Key Advantages Leak Detection Case Studies Condition Assessment Background Condition Assessment Case Studies Summary 3 Correlation Theory Correlation: a Review • Old technology: proven on metallic distribution mains • Manufacturer’s began to work on plastic and other types of pipes: made claims that could not be consistently achieved! • Required a different approach to: ▸ Sensors ▸ Signal Processing ▸ Amplifiers • Echologics achieved some extraordinary success, other manufacturers immediately introduced ‘trunk main correlators’, but have never achieved our level of success • Development continues; now on our 5th generation of hardware 5 Correlation Theory • Leaks make noise • Time of flight technology • Correlation function: ▸ Leak bracketed with 2 Sensors ▸ Leak noise takes longer to arrive at Sensor 1 than Sensor 2 ▸ Correlator measures time difference to identify exact leak location 6 Why is Echologics Successful • Advances in sensor design, signal processing, correlation algorithms • Advances in post processing of data • Advances in field techniques • It is as much about the people, as it is about the equipment 7 Sensor development • We have done extensive R&D into plastic and transmission main sensor requirements, developed both hydrophones and accelerometers for large diameter The People • We have an intense training program and detailed field / data analysis processes • We have a young, passionate team of engineers 8 Echologics Correlation Advantages Advantage and Disadvantages • Advantages: ▸ ▸ ▸ ▸ ▸ Easily implemented with existing fittings No requirement to close service take offs or laterals No requirement to alter the flow in the pipe Can ‘see’ leaks many km away; will find largest leaks first Will find small leaks (typical results 2 LPM on 1500mm pipe at 3.5 bar, 1100m) • Disadvantages: ▸ Will not find very small leaks (<1LPM) ▸ Accuracy of location needs to be carefully verified 10 Technology Comparison Technology Pros Cons Traditional Correlation • Non-Intrusive and Non-destructive • Poor performance on PVC and Large Diameter (LD) mains Echologics Correlation • Same as above • Works on PVC and LD mains • Cost Effective • Cannot find small leaks (<1 lpm) • ‘Averaged’ condition assessment results In-Pipe Tethered and Free Swimming • Can find small leaks • Intrusive • Works on long • Special Insertion sections of pipe with Points are required minimal access • Isolation of all laterals is required 11 Leak Detection Case Studies Case Study: SABESP • • • • Leak discovered by Smart Ball Pilot Dry hole had been dug based on Smartball location Requested by Genival Abdias to try and pinpoint the leak Echologics correlated the leak to within <1m accuracy 13 13 Site Location 14 Leak Location Excavation 15 Successful Leak Location 16 Case Study: United Water New Jersey • Echologics performed a transmission main leak detection pilot survey on 8km of UWNJ transmission mains ▸ 24” to 42” diameter • Testing revealed 5 leaks • One major leak discovered on a pipeline section outside of the boundaries of the original test plan • We first saw this leak 3 km from the eventual location 17 Out of Bracket Leak Detected Correlations provided evidence of leakage outside the current test area 18 Isolated Leak Under a Stream • Correlation across the river crossing revealing a prominent peak 40m east of fitting on the main 19 UWNJ 42” RCP Repair Pictures 20 Other Examples: • • • • Thames Water, England Bristol Water, England Las Vegas Valley Water Department Springfield, Massachusetts ▸ Echologics confirmed 2 leaks that was already discovered by expensive in-pipe technologies - 36”(915mm) and 48” (1200mm) main • Sydney, Australia • Barrie, Ontario • New Orleans 21 Condition Assessment Background Remaining Pipe Wall Thickness Measurement • Metallic pipes lose thickness from internal and external corrosion • Asbestos cement pipes lose “effective thickness” from aggressive waters leaching calcium out of cement and weakening walls • Physical wall thickness doesn’t change, but the pipe loses structural stiffness and strength 23 Velocity Measurement Noise Source Measure the sound velocity Wave propagation velocity (v) = D/ΔT, where ΔT is time delay between signals 1 and 2 24 Minimum1 Average2 Wall Thickness 1. Minimum around the circumference 1. Averaged along the length 25 Las Vegas, NV: LVVWD Pilot • Two sections of 6” AC pipe tested • .73” remaining structural thickness was measured by Echologics • Results indicated that pipe met requirements of PC200 • Excavated pipe to confirm results • Testing confirmed that our results accurately represented the remaining structural thickness of the pipe 26 Las Vegas: Velocity Measurement & Results Program Input Pipe Diameter (m) Output Wall thickness (mm) Wall Thickness (in) 0.1524 18.5 0.73 27 Las Vegas, NV: Excavated Pipe 28 Results of 14” lab testing 29 Pink area represents structurally sound concrete White area has lost structural integrity 30 Newark, NJ: Pilot on cast iron pipe • Pilot study on cast iron pipe installed in 1910 • Pipe had been chosen for cement mortar lining as a rehabilitation technique • Our study determined that it was highly degraded and required a structural lining • We also found a leak during the study, losing about $20,000 worth of water a year 31 Newark, New Jersey Fire Hydrant Service Leak at House #195 Average Pipe Wall Thickness of 0.18”, 63.9% loss Pit #1 Valve Pit #2 Pit #3 32 32 Newark, New Jersey This is the remaining structural thickness! Confidential 33 33 Other Examples: • • • • Dayton, Ohio Sweetwater, California Hamilton, Ontario Chicago, Illinois ▸ Successfully identified 3000ft section of reinforced concrete cylinder pipe with a significant number of wire breaks • Calgary, Alberta • Maple Ridge, British Columbia • Bloemfontein, South Africa 34 Summary • Echologics has pioneered the effective use of correlators on large diameter pipe, and continues to develop the technology • In North America, we are now considered a viable alternative to insertion technologies: numerous successful studies have been completed • Claims made by other manufacturers continue to throw the technology into doubt • In several projects we have been directly compared to Sahara and have found the same leaks • Our condition assessment technology can accurately determine the remaining structural wall thickness of pipes • There is return on investment from: • • • Prioritizing which pipes require rehab or replacement Performing leak detection simultaneously Ensuring the correct decision is made with respect to rehab or replacement 35