Company Brochure - Suneet Engineering Pvt. Ltd.

Formally Known As- Nagpure Engineering Co.

Established - 1982

Founder - Mr. Suryakant T. Nagpure.

Specialist in

Press Components

Sheet Metal Forming

Pipe Bending

Pipe End Forming

Fabrications

Certification

ISO - 9001:2008 (TUV Austria)

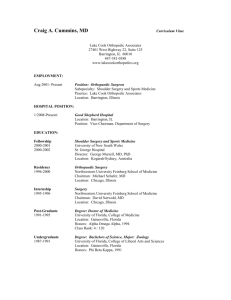

Mr. Suryakant T. Nagpure

Mr. Surendra T. Nagpure

Mr. Suneet S. Nagpure

(Chairman & M.D.)

(Director)

(Director)

Chairman & Managing Director

Mr. Suryakant T. Nagpure

Director Technical

Mr. Suneet S. Nagpure

Management Representative

Plant Manager

Development Engineer

Trainee

Development

Engineer

Quality Control

Trainee Quality Control

Production Engineer

Line Managers

HR

Director Commercial

Mr. Surendra T. Nagpure

Accounts Head

Accountant

Stores

Purchase

Plant – I (Location: Dattanagar)

1.

Shop Floor – 15,000 sq. ft.

2.

Office – 1,000 sq. ft.

3.

Stores – 1,000 sq. ft.

Plant – II (Location: Narhe) Expanded Plant.

1.

Shop Floor – 12,000 sq. ft.

2.

Office – 3,100 sq. ft.

3.

Stores – 1,600 sq. ft.

1. 4500 sq. ft.

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Cummins India Limited – Kothrud

Cummins India Limited – PGBU

Cummins India Limited – EOU

Cummins India Limited – CPD

Cummins India Limited – B Upfit

Cummins India Limited – DTA

Cummins India Limited – Spares

Cummins India Limited – ReCon

Cummins India Limited – DTA Spares

Lister Peter Limited – U.K.

Simpson & Co. Limited – Chennai

ELGI - Coimbatore

Tata Motors Limited

Kirloskar Oil Engine Limited

Nelson Global Products India Private Limited

Hindustan Hardy Spicer

Fluid Trans.

Atlas Capco

Indian Railway

Suneet Engineering Pvt. Ltd. Is Committed to

Maximize Customer Satisfaction Through

Continual Improvements In The Quality, Delivery

Of Our Products, Implemented Quality

Management System & Envoirment Which Has

Impact On Our Business As Well As Society By

Process Approach.

We Will Strive Hard For The Continuous Growth Of

Our Employees & Business.

Minimum Wastage of All Kind.

100% Monthly Delivery Performance.

Trained Employees.

No Repetitive Complaints.

Customer Satisfaction.

Robotic Plasma Cutting

Plasma Cutting Machine HPR 260 - Hypertherm.

Robot – ABB

32 mm Piercing & 64 mm Edge Cutting

3D Cutting

Length - 5,000 mm

Width – 1,800 mm

Windows Been

Formed On The

Pipe On 3D

Robotic Plasma

Cutting

3D Cutting with Robotic Plasma

Cutting

Robo – Motoman

Co2 Welding System – Motoman

Special Skills - Programming for All Products Done

In-house. This help us reducing the Programming

Cost and Time.

Four Pipe Bending Machines

Three Pipe Bending Are NC Controlled

Pipe Bending Range

8 mm to 125 mm

Minimum Bend Radius 1.2 D.

Maximum Bend Radius As Per Customer

Requirement

63 Ton Press

120 Ton Press

I) Machine 1

Capacity – 63 Tons.

Used For Deep Draw Operation.

Deep Draw Done Upto 300 mm.

II) Machine 2

Capacity – 120 Tons.

Deep Draw Done Upto 300 mm.

Specially Used for

Numbering All

Kinds

Of Dipsticks

Specially

Designed In-

House for

Leakage Testing.

Capacity - 13mm thickness.

Blade Size - 2,500 mm.

Introduced for De-burring of High Volume

Small Components

Time Consumed

Per Lot – 15 Mins.

Payload – 46 Kgs.

Introduced in year – 2011 at

Plant I (Dattanagar).

Manages Inventory

Manages Purchase Orders

Manages PO Schedules

Manages GRN

Manages MRN

Manages all QC Pending

Reports

Operation-wise Part Report

Tracking of Kan-ban System

Tracking of MRP.

Manages Min/Max Stock Level.

Manages Quotations.

Couplings

Breathers

Rack & Lever

Assembly

Stainless

Steel Float

Delivery

Tube

Air Breather

Pipes

Pipes

Reductions,

Welding

Pipes

Bending,

Flaring

Cover Plates

Cover Plates

Best

Performer in

Cost

Reduction

Year - 2003

Active Participation Society Organized Sports.