ppt - Sustainable Sanitation

advertisement

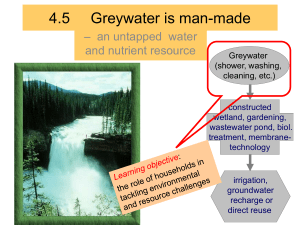

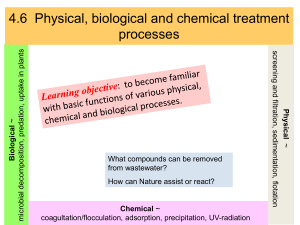

4.7 Greywater treatment Learning objectives: Get familiar with various treatment options and with the application of various processes Greywater (shower, washing, cleaning, etc.) constructed wetland, gardening, wastewater pond, biol. treatment, membranetechnology irrigation, groundwater recharge or direct reuse Application of processes G F A B D E C BOD, suspended solids Physical Jan-Olof Drangert, Linköping university, Sweden Overview of possible technical options Treatment: Possible technical solutions for greywater: Physical (SS and BOD-levels) Screen, grease trap, septic tank, sedimentation pond Biological I (BOD-level reduction) ABR, anaerobic filter, UASB, soil filters, reactive filters, trickling/bio-filter, stabilisation pond, subsurface wetlands, irrigation Biological II (N & pathogen reduction) Nitrification-denitrification in wetland or sandfilter, maturation pond, crop production, mulch beds, overland flow Chemical soil filters, reactive filters, precipitation pond, (P, pathogen, metal removal) irrigation Sludge management Thickeners, centrifuge, sieve, fermentation, lime, drainage bed, reed beds, composting, lime stabilisation Karin Tonderski, Linköping univeristy, Sweden Screens and grease traps screen Overflow Organics from kitchen pipe sorted out in a plastic screen Jan-Olof Drangert, Linköping university, Sweden Sedimentation pond Karin Tonderski, Linköping university, Sweden Simple septic tank Scum layer Bird’s eye view Sediment Sediment Jan-Olof Drangert, Linköping university, Sweden Anaerobic pond CH4, CO2 scum layer sludge Karin Tonderski, Linköping university, Sweden Off-plot system Anaerobic Baffled Reactor (ABR) Anaerobic baffled reactor Pedro Kraemer, BORDA, India Anaerobic Filter (off-plot biogas system) Courtesy of Pedro Kraemer, BORDA, India UASB Reactor biogas Air pump Jan-Olof Drangert, Linköping university Horizontal subsurface flow wetlands o2 o2 o2 o2 Internal water level Influent Outlet shaft Cross distribution trench Main filter filled with graded gravel and sand Cross collection trench Collection and drainage pipe Effluent Courtesy of Roshan Shrestha, UN-Habitat, Nepal Construction of horizontal flow wetlands Karin Tonderski, Linköping university, Sweden Soil filters – leachfield or mound systems Jan-Olof Drangert, Linköping university, Sweden Trickling filter Jan-Olof Drangert, Linköping university, Sweden Vertical flow subsurface wetland o2 o2 o2 o2 Influent Main filter filled with graded gravel and sand Collection and drainage pipe Effluent Courtesy of Roshan Shrestha, UN-Habitat, Nepal (revised) Biofilter and wetland for greywater treatment Biofilter with nozzle distribution Wetland Total area 100 m2 Courtesy of Thor-Axel Stenström, SMI, Sweden Common problems in soil filters 1. Overloading (suspended solids, high BOD, water) 2. Uneven distribution (over surface, over clay) 3. Failure in drainage (waterlogging, roots) 4. Wrong choice of sand and gravel (texture, 1mineral particle shape) 2 3 4 Jan-Olof Drangert, Linkoping university, Sweden Improved distribution using controlled clogging Geotextile unit Pre- treatment in sedimentation tank 10 m 0.6 m in sand 3 m in silt Courtesy of Peter Ridderstolpe, WRS. Sweden Bird´s eye view of a mulch bed system for a single house Registro de Distribution división de flujos boxes Mulch beds Cajete de acolchado Bath kitchen Wash room Courtesy of Kim Andersson, Colombia Mulch bed filter Greywater pipe from household Aguas grises de cocina, lavamanos, regadera o lavadero Mulch from Acolchado de hojarasca, paja o garden viruta de madera Isla de tierra Cajete Depth max. 40 cm Entrance Punto de efluente with cubiertostones con piedras 3-10 litres of greywater per m2 per day Courtesy of Kim Andersson, Colombia Wetland irrigation and overland flow Karin Tonderski, Linköping university, Sweden Aerobic biofilters and energy Extensive Sorption and irrigation systems Intensive Rapid infiltration systems - Drain mulch basin Soil filters: - Swales & resorption trenches - Infiltration (open, covered submerged - Wetland irrigation (overland flow & subsurface flow, and impounding wetlands) - Sandfilters Artificial filter media: - Indrän, infiltra etc. Biofilter reactors - Trickling filter - Bio-rotors Revised from P. Ridderstolpe, WRS, Uppsala Removal rate of microorganisms in various wastewater treatments (log units) Process Primary sedimentation: Plain Chemically assisted Bacteria Helminths Viruses Cysts 0-1 1-2 0-2 1-3 0-1 0-1 0-1 0-1 UASB 1-2 Activated sludge 0-2 0-2 0-1 0-1 Sub-surface flow wetland 1-2 2-6 2-3 0-2 Aerated lagoon 1-2 1-3 1-2 0-1 Slow sand filtration/infiltration 2-3 3-6 2-3 3-6 Disinfection 2-6 0-1 0-4 0-3 Waste stabilization pond 3-6 1-3 2-4 1-4 Large variations in practice due to quality of management Sources: WHO, 2006 and Jimenez et al., 2010 E: Limits Cd Old 20-40 New 5 Cr 150 Treatment of sludge Cu Hg Ni 1,100- 16-25 300-400 1,750 400 5 50 New limits on organics proposed under Option 3 from EU (2008) PAH 6 mg/kg dry matter PCB 0.8 mg/kg dry matter PCDD/F 100 ng ITEQ/kg dry matter LAS 5 g/kg dry matter NPE 450 mg/kg dry matter Pb Zn 7501,200 250 2,5004,000 600 - All treatment processes produce sludge, be it much or little -Choice of treatment according to kind of reuse - We need to de-toxify our chemical society Source: EU, 2008 Start from the end ! (centralised example) We decide what quality we would like the final products to have. Sludge drying bed CO2 & methane gases Our thinking is now on global challenges as well as on local wishes for system performance and status percolating effluent water Jan-Olof Drangert, Linköping university, Sweden Pathogen reductions achieved by selected health-protection measures Control measure Wastewater treatment Reduction Comments (log units) 1-4 Drip irrigation: - low-growing - high-growing 2 4 Pathogen die-off 0.5-2 per day Usually achieved reduction but depends on type and functionality of the treatment system Root crops and crops such as lettuce that grow just above but partially in contact with soil. Crops such as tomatoes and fruit trees not in contact. Die-off on crop surfaces between last irrigation and consumption, depends on sunshine, crop type etc. Crop-washing: - with water - disinfection 1 2-3 Washing salad crops, vegetables and fruit with: clean water. Weak disinfectant and rinsing in clean water. Produce peeling Produce cooking 1-2 6-7 Fruits, cabbage, root crops. Immersion in boiling or close-to-boiling water. Source: Bos, R., Carr, R. and Keraita, B. 2010. Environmental and Human health hazards Pathogenic microorganisms Numbers A few hundreds: handfull unknown added each year Exposure In food, by skin penetration, insect bites, in aerosols. Dose- One up to millions; a few to response millions needed for infection Chemical compounds 100,000 man-made; Hundreds new man-made added each year In food, by skin penetration, on skin, in aerosols. Water bodies, soil accumulation Nano- to microgrammes; small amounts that may accumulate. Vulne- Humans but not environment. Both humans and environment. rable Mainly children & elderly All, but particularly babies Barriers Wash hands & veggies, no Only biodegradable, caution finger in mouth, heat food, etc with medicines, effluents to soil Jan-Olof Drangert, Linköping university, Sweden Summary of strategies to improve wastewater treatment and nutrient use in agriculture and energy production Principle: • • • • • Organic ≠ other solid waste Stormwater ≠ sewage Industrial ≠ household wastewater Black toilet water ≠ greywater Faeces ≠ urine Jan-Olof Drangert, Linköping University, Sweden