Rural Development - Great Lakes Water Conservation Conference

Life Cycle Assessment for

Cheese Plants

FX Milani

UW-Madison

Wisconsin Dairy Products Association

September 28, 2010

FIL/IDF, UN-FAO dairy report

World dairy contributes 4% of all manmade green house gases

Nat’l Project Cheese & Whey LCA

Wisconsin cheese and whey

Who: Rural development is VERY interested in the contribution of cheese/dairy manufacturing

What: Concern about sustainability issues, want to find “hot spots” and new potential returns

Wisconsin cheese and whey

Where: Wisconsin based manufacturing

When: This year and next spring, beyond?

Why: Ultimately, dairy manufacturing is vital

How: Survey work to get baseline concerns and data, model potential ideas, investigate best ideas

The projects: 3 this year

◦ Sustain Metrics:

UW Food Science, CDR,UW Biological Systems Engineering

F. Milani, D. Reinemann, D. Sommer, students

Modeling, Survey audits, Outreach program, Reports

◦ Whey Disposal:

UW Food Science, CDR, Industrial Partners

F. Milani, M. Molitor, D. Sommer, Contractors

Survey audits, Whey/permeate data, Waste water data,

Reports/potential

◦ Sustainability Outreach:

UW Food Science, Biological Systems Engineering

F. Milani, A. Newenhouse

Short course, Involvement with 2011 WCMA LaCrosse,

Outreach materials, Bus trips

Specific information to collect

Energy use: gas, electric, wood, LP, etc

Transportation use

Refrigerant use

Raw material, chemical use

Packaging use

Water use, wastewater generated

Pounds and types of cheese produced

Milk composition

Water

Fat

(emulsion)

Protein

87.8%

3.7

3.1

( colloidal suspension)

Casein (2.5)

Lactoglobulin (0.3)

(true solution)

“

“ Lactalbumin

Others

(0.07)

(0.22)

Lactose 4.7

Minerals (ash) 0.7

Cheese Yield 10%, ~50% solids loss to whey

Percent milk constituents

Milk is high in phosphorous

Food item

Milk

Cream

Eggs

USDA Handbook 8 mg of P / Liter

930

710

1800

Cheese P loss to whey (50-90%)

Cheese Type mg of P / Liter

Cheddar 546

Colby

Jack

526

575

Mozzarella

Swiss

Brick

519

447

465

(Wendorff & Matzke, 1993)

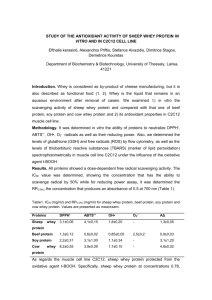

The 4 F’s of whey

High

Value

$

Low

Value

$

FOOD

Feed

Fuel

Fertilizer

Options for whey

Sell to aggregate processor

Land spread

Concentrate and sell (wet or dry)

UF concentrate, sell wet protein

◦ Permeate: sell wet or land spread

UF concentrate, sell dry protein

◦ Permeate: sell dry lactose, dry/landspd wet DLP

◦ (note: lactose market is very volatile)

UF concentrate, sell wet protein

◦ Permeate: biogas, dump minerals

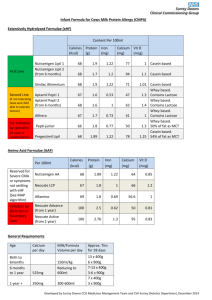

Average Wisconsin cheese plant

44.7 M pound cheddar cheese annually

28.8 M pounds sweet whey equivalent

447 M pounds milk (1.2 M pounds per day)

116 k gal per day water use, high vary

230 k gal per day wastewater flow, med vary

14,355 kWhr per day electric

6568 therms per day natural gas

459,801 pounds of caustic annual use

Citations listed at end of presentation

Wastewater and Carbon Footprint

Short Courses, November 9-11 http://www.foodsci.wisc.edu

http://www.cdr.wisc.edu

Citations for average cheese plant

Cheese production: http:www.nass.usda.gov/Statistics_by_State/Wisconsin/ f

Publications/Annual_Statistical_Bulletin/annbull_2008.pd

Whey conversion: USDA Handbook 8

Milk Input: Van Slyke equation for cheddar cheese

Water use: Fietz et al. Int. J. LCA 12(2) 109-17, 2007

Wastewater output: Danalewich, et al. Wat. Res. 32(12)

3555-68, 1998

Electric and natural gas use: C. Ling et al. USDA report,

2004

Sodium Hydroxide use: Fernadez, et al. J. Food Eng 97,

319-28, 2010

How much energy is in permeate?

Yield of pure carbohydrate is 0.38 cubic meter methane per kg lactose

1 kg lactose is 13,300 BTU, or 0.133 therm

1 therm is $0.475

1 kg lactose is $0.063, or $0.029 per pound

Current market lactose is $0.29-0.35, less drying cost at about $0.19, plus operational

3-12 cents, profitable now, but…

Wet permeate is 4.5% lactose

Carbon credits with lactose

1 kg lactose produces 0.38 cubic meters methane, and 0.74 kg CO2

2685 kg of lactose produces mton CO2

Assume EU trading at $15 per mton, get additional $0.0055 per kg lactose ($0.0025 per pound)

$50,287 per year new revenue

Consumer milk is burdened with1.2 CO2 per kg milk. Milk contains 45 g lactose, potential 0.033 kg CO2 / kg milk carbon credit from lactose

Whey processing steps

Drained Whey

Fines Saver

Separator

Clarified whey

RO

Pasteurization

Evaporator

Cheese Fines

Whey Cream

Condensed

Whey

To Processor

Whey Processing steps

Condensed Whey

Crystallizer

Spray Dryer Dry Sweet Whey

Whey Protein Concentrate

Permeate processing

Important nutrients in whey

Nutrient Whole whey Whey permeate

N 12.2

2.0

P 4.0

3.8

K

Ca

Mg

Na

14.6

2.9

0.55

4.2

8.2

2.7

0.59

3.4

Benefits to landspreading

Nutrient recycling

Residual fertility

Soil physical properties

Cost effectiveness

Pollution reduction

Land spreading, Chloride, WI

Ave. Cl (mg/L) Gal/A/yr.

Whey/permeate 1183 16,000

Salty whey

Used brines

56,900

187,000

500

89

Issues with landspreading

Nitrogen content

Salt concentration

Soil oxygen levels

Odors

Soil limitations

Seasonal limitations (injection)