Introduction to PHA & Risk Matrix

advertisement

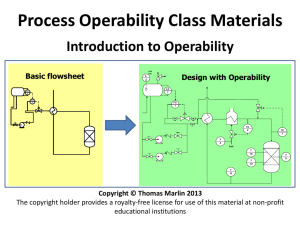

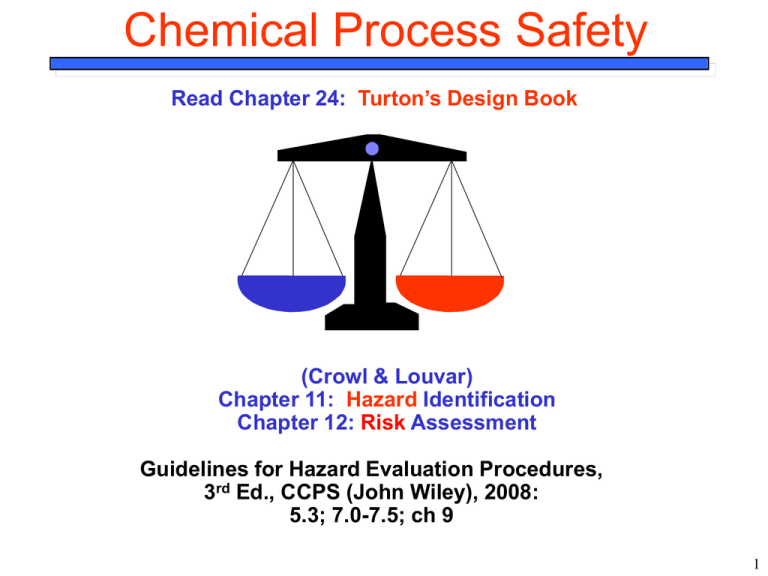

Chemical Process Safety Read Chapter 24: Turton’s Design Book (Crowl & Louvar) Chapter 11: Hazard Identification Chapter 12: Risk Assessment Guidelines for Hazard Evaluation Procedures, 3rd Ed., CCPS (John Wiley), 2008: 5.3; 7.0-7.5; ch 9 1 Introduction SAFE PROCESS DEVELOPMENT Synthetic Desktop organic screening, chemistry databases, ideas calculations Discovery research and multiple experiments CHEMICAL Desktop studies Micro and mini scale reactors Automated Calorimeters and reactors Automated laboratory reactors. Process optimization Pilot plant studies PR O C E S S Kinetics, modelling, simulation LIFE Scale up and design Industrial production. Debottlenecking. Optimization of mature processes. Retrofits. CYCLE Adiabatic HAZOP, calorimeters HAZAN, HAZID Design reappraisal, relief systems, dump and quench tanks Objective is to move from the earliest phases of research and development through to full scale production in a confident, safe and cost effective manner D. Crowl, notes 2 Figure 11-1 Hazards identification and risk assessment procedure. (Adapted from Guidelines for Hazards Evaluation Procedures (New York: American Institute of Chemical Engineers, 1985), pp. 1–9.) 3 Process Hazard Analysis – Many Options 1. 2. 3. 4. 5. 6. 7. What-If Checklist What-If/Checklist FMEA – Failure Mode & Effects Analysis FTA – Fault Tree Analysis Hazards Surveys HAZOP – Hazards & Operability study 4 Process Hazard Analysis – Many Options 1. 2. 3. 4. 5. 6. 7. What-If Checklist What-If/Checklist FMEA – Failure Mode & Effects Analysis FTA – Fault Tree Analysis Hazards Surveys HAZOP – Hazards & Operability study 5 1. What-If Analysis • Unstructured method for considering results of unexpected events • Uses questions beginning with "what-if“ • Not concerned with "how" failures occur • Purpose is to identify problems that could lead to accidents • Results in a list of potential problem areas and suggested mitigation methods 6 What-If Example LNG Vaporizer What if: (a) Water flow is stopped? (b) LNG flow is stopped? (c) Natural gas temperature is too low? (d) Water flow is too low? (e) Water pressure is too high? (f) A tube leaks into the shell? (g) Inlet water temperature is too low? D. Crowl, notes 7 What-If Example LNG Vaporizer What-If Consequence/ Hazard Recommendation Water flow is stopped? Water in shell freezes and may rupture shell; natural gas temperature too low. Automatic interlock to stop LNG flow if water flow is stopped. LNG flow is stopped? Not Hazardous None Natural gas temperature is Downstream piping may Monitor gas temperature; become embrittled. too low? low temperature alarm. Water flow is too low? Natural gas temperature Monitor flow rate; low may be too low; water may flow alarm. freeze in tubes. D. Crowl, notes 8 6. Hazards Surveys Can be simple like inventory of hazardous chemicals More rigorous procedures: - Dow Fire & Explosion Index - Dow Chemical Exposure Index 9 6. Hazards Surveys: Dow Fire & Explosion Index • Complex and detailed procedure carried out by an individual • Rates relative hazards of storing, handling, processing flammable and explosive materials • Systematic approach independent of judgmental factors • Break the process down into units or sections, e.g. the reactor, storage tank or a pump • Use experience to select the units or sections that have the highest likelihood of a significant hazard (too many to cover all); may use checklist approach to choose • Define the material factor (what chemicals are being used); in general, higher the value the more flammable / explosive • Adjust this with various penalties based on conditions such as storage above normal boiling point, exothermic reaction, etc • Then take credits for safety procedures and safety systems • Finally arrive at a number that rates the hazard; compare with table / experience 10 6. Hazards Surveys: Dow Fire & Explosion Index Dow Fire & Explosion Index standard form; C&L Fig 11-3 Penalties MF F1 Material factor General Process Hazards Factor Penalty factors F2 Special Process Hazards Factor D. Crowl, notes 11 6. Hazards Surveys: Dow Fire & Explosion Index Dow F&EI - Determining the degree of hazard, Table 11-2 F&EI index value 1 – 60 61 – 96 97 – 127 128 – 158 > 158 Degree of hazard Light Moderate Intermediate Heavy Severe D. Crowl, notes 12 7. Hazard and Operability (HAZOP) Study HAZOP is a Structured "What If" Type of Study • Objectives - Identify Hazards - Identify Operability Problems • HAZOPs Use Team Approach • Multi-Disciplinary • Guide word based • Structured and Systematic 13 Hazards and Operability Study Investigative Process • Select study nodes – – – – – Major process vessels Major process lines connected to process vessels Pumps and compressors Heat exchangers Major support systems • Pick a process parameter - Flow, level, temperature, pressure, volume, pH, concentration, agitation, etc 14 Hazards and Operability Study Investigative Process (Cont’d) • Apply guide words to process parameters – Determine deviation from design – Determine consequences of deviations – Evaluate consequences • Typical causes of deviations – Hardware failures – Human error – Outside forces – Unanticipated process state 15 Hazards and Operability Study Investigative Process (Cont’d) • Suggested actions – Change in design – Change in equipment – Alter operating procedures – Improve maintenance – Investigate further • HAZOP Follow-up – Assign responsibility for carrying out recommendations with agreed timetable – Refer recommendations to appropriate managers – Evaluate and review • Record keeping – Copy of all data used – Copy of all working papers – HAZOP worksheets 16 Hazards and Operability Study Guide Words and Their Meanings Simple words or phrases used to qualify the intention and associated Guide Words & Symbols Application to Input in Material parameters order to Desired Activity toApplication discover deviations. Design Intent The intended material including quantity, chemical composition and input physical condition. The intended activity. May be one major and one or more dependent minor activities. NO The intended material is not present but no substitute material present. The intended activity does not occur but no direct substitute activity takes place. MORE A greater quantity of material than intended, e.g., "Higher Pressure". A greater activity than intended, e.g., flow rate, pressure rise, heat input, chemical reaction, duration of activity etc. LESS A lesser quantity of material than intended, e.g., weight or volume. Lower physical condition, e.g., "Lower Pressure". A lesser activity than intended, e.g., flow rate, pressure rise, heat input, chemical reaction, duration of activity etc. Further Applications Further intentions, e.g., sources or destination. 17 18 HAZOP Example • Chemistry is such that concentrations of B must not exceed that of A • First Study Node - pipeline from suction side of pump that delivers A to the reaction vessel • First Guide Word - No to design intent of transfer A • Causes of Deviation – – – – Supply tank is empty Pumps fail to run Pipeline is fractured Isolation valve is closed • Consequences – Excess of B over A could lead to an explosion • Recommendation – Install interlock device on pump B into reactor 19 HAZOP Example Worksheet D. Crowl, notes 20 W. Buck, SDSMT Seminar, 2012 21 Risk Matrix Frequency Consequence Negligible Marginal Serious Critical Catastrophic Frequent D C B A A Probable D D B B A Occasional D D C B B Remote D D D C B Improbable D D D D C Unacceptable Undesirable Marginal Risk = F x C Acceptable B.K. Vaughen, PSM Overview, SACHE, 2012 22 Risk Equation Risk = Frequency x Consequence Operational Discipline Frequency How often the event may occur - its likelihood is a “probability” Consequence How severe the event may be - an undesired result of the event B.K. Vaughen, PSM Overview, SACHE, 2012 23 Operational Discipline OD The personal commitment of everyone to ensure their personal and process safety by 1) performing their tasks correctly, and 2) recognizing, responding to and seeking help, as needed, to unanticipated situations or conditions. B.K. Vaughen, PSM Overview, SACHE, 2012 24 Operational Discipline “Organizational” OD Leadership Focus Employee Involvement Practice Consistent With Procedures Excellent Housekeeping “Personal” OD Awareness Knowledge Commitment B.K. Vaughen, PSM Overview, SACHE, 2012 25 Risk Reduction Risk = F F x C OD Frequency Engineering and Administrative Controls C Consequence Inherently Safer Processes Emergency Response Design Phase: the best time to use ISP B.K. Vaughen, PSM Overview, SACHE, 2012 26 Risk Reduction Risk = F x C OD OD Operational Discipline Safety Culture Organizational OD Safety Behavior and Personal OD Commitment Characteristics B.K. Vaughen, PSM Overview, SACHE, 2012 27 Effect of Poor OD on Risk Frequency Consequence Negligible Marginal Serious Critical Catastrophic Frequent D C B A A Probable D D B Occasional D D C B B Remote D D D C B Improbable D D D D C Unacceptable Undesirable Marginal Acceptable Actual Risk B A Perceived Risk Risk = F x C OD B.K. Vaughen, PSM Overview, SACHE, 2012 28 Risk Matrix W. Buck, SDSMT Seminar, 2012 29 PSM Systems Designed to minimize process safety risk: Risk = F x C OD There is always some level of risk Our PSM-related risk reduction efforts are compared and evaluated against other potential business risks (i.e., environmental, operational, maintenance, quality and financial) B.K. Vaughen, PSM Overview, SACHE, 2012 30 31 B.K. Vaughen, PSM Overview, SACHE, 2012 32 Questions? 33