No Slide Title

advertisement

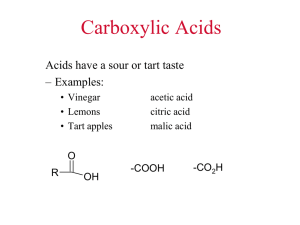

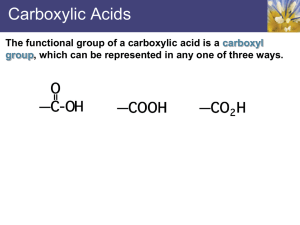

Methods for Volatile Fatty Acids (VFA) Separation and Recovery from Complex Effluent Streams M.P.Zacharof *¹and R.W. Lovitt *² CWATER College of Engineering, Centre for Water Advanced Technologies and Environmental Research Swansea University (CWATER)SA2 8PP, UK*¹ College of Engineering, Multidisciplinary Nanotechnology Centre (MNC), Center of Complex Fluids Processing (CCFP), Centre for Water Advanced Technologies and Environmental Research (CWATER) Swansea University , Swansea, SA2 8PP, UK*² Methods of Production of Volatile Fatty Acids Carboxylic acids are heavily involved with organic carbon cycling on the planet. They are extensively used in the industry and are typically produced of oil based chemical processing. On the other hand most organic carbon in environments goes through fatty acid intermediates as they are ultimately metabolized either to carbon dioxide (CO2) and methane anaerobically or CO2 and water in oxidative systems [1]. The removal of Volatile Fatty Acids (VFA), from wastewater from numerous sources such as chemical plants has been an area of great research interest. With the global petroleum resources facing scarcity and the constantly rising awareness of the environmental impact the carbon based economy has created, research on alternative methods of their production, such as anaerobic fermentation (Fig.1) and digestion. Commercial Importance of Volatile Fatty Acids Other uses of VFA do include their usage in the food industry as flavouring and antimicrobial agents and in the pharmaceutical and cosmetics industry as raw materials. Certainly one of the most important VFA commercially is acetic acid, consumed worldwide, with about one third of its consumption occurring in United States. Global production of acetic acid is approximately 6.5-7 million tonnes/year, at a price of $600800/t. Of the global demand of acetic acid,1.5 mt/year) is met by recycling; the remainder is manufactured from petrochemical feedstock, produced by oxidation of acetaldehyde, the oxidation of liquid phase hydrocarbons, the carbonisation of methanol or from biological sources [2]. Separation Methods of Volatile Fatty Acids Separation of volatile fatty acids can be achieved using a variety of physical and chemical methods, the most important tabulated below. Methods Description Advantages Disadvantages Precipitation Calcium salts are added in the medium, to neutralize the acids. The resulting calcium carboxylate solutions, can be concentrated by evaporation, then crystallized and separated of the mother liquor Well established. Higher product yields, low capital costs, products of high purities Generating solid wastes as sulfuric acid is used to release carboxylic acids from the calcium carboxylates. Distillation Ammonia is used to neutralize the acids reacting to form ammonia carboxylate, which is then mixed with alcohol to form esters , to be separated by distillation Well established Highly pure products, byproducts can be used as fertilizer High energy and capital costs related to distillation that is used to separate the alcohol from carboxylic acids after the formed esters are hydrolyzed. Adsorption Ion exchange resins used to exchange to adsorb carboxylate ions of the feeds Well established. Easily operable Electrodialysis High resin costs, High energy demand due to resin regeneration, low adsorption capacities, separation is not highly selective Negatively charged carboxylate Carboxylate is The products have high ions move through an anion concentrated in impurities, further exchange membrane towards aqueous solution , purification might be the anode in the electrodialyzer does not require acid required, difficulties in scaling through electric current treatment to adjust up, high energy demand. pH Prone to fouling Solvent Extraction Organic acids use to extract carboxylic acids from the stream Higher product yields, suitable for carboxylate salt production, lower costs Membrane Separations Use of membrane filters of various pore sizes to treat the mixed effluents for solids removal and fractionate the desired substances for recovery Developing Membrane fouling , clogging, technology, High largely untried in complex product yields, waste systems. suitable for a wide range of applications, low energy. economic, easy to scale up Fig.1 Diagram of Fermentation Process In anaerobic digestion (Fig.2) the hydrolysis of target solid wastes followed by the microbial conversion of them to biodegradable organic content results in the production of intermediate organic acids, specifically VFA. VFA are often detected at high concentrations in the effluent streams and mixed liquors of anaerobic membrane reactor systems, because of sudden variations in hydraulic and organic loading rates [3]. Table 1 Suitable Separation methods for Volatile fatty acids from complex streams Fig.2 Diagram of Anaerobic Digestion Commercial Importance and Value of Volatile Fatty Acids Acetic, propionic and butyric acid are also attracting attention as potential candidates for synthesis of high value biodegradable plastics production replacing petrochemical feedstock (Fig. 3). Conclusions • VFA are substances of great value and wide use in the industry nowadays and further application VFA from waste can substitute for fossil carbon sources. • Anaerobic Fermentation of liquid or solid media have potential for economical production from waste directing carbon away from methane combustion so reducing the carbon foot print while creating a source of valuable carbon materials. • A review of the recovery processes shows that they are a significant barrier to implementing such strategies however, membrane technology in particularly nanofiltration, possibly used in combination with other processes, offers a relatively cost-effective recovery method.. 1. 2. 3. Fig.3. Price range of Volatile Fatty Acids The feed needs to be acidified for efficient extraction, extractants needs to be regenerated by distillation or back extraction. References Mostafa, N. A. (1999). "Production and recovery of volatile fatty acids from fermentation broth." Energy and Consumption Management 40: 1543-1553. Katikaneni, S. P., Cheryan, M. (2002). "Purification of fermentation-derived acetic acid by liquidliquid extraction and esterification." Industrial Engineering Chemical Resources 41(2745-2752). Dinsdale, R. M., Premier, G.C., Hawkes, F.R., Hawkes, D.L. (2000). "Two-stage anaerobic codegestion of waste activated sludge and fruit/vegetable waste using inclined tubular digesters." Bioresource Technology 72: 159-168.