Lettuce/Fish Polyculture for the American Insular Pacific

advertisement

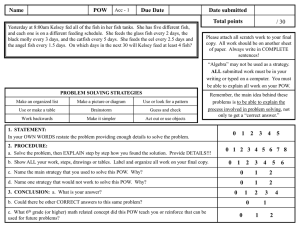

Harry Ako and PingSun Leung Depts. of Molecular Biosciences and Bioengineering and Natural Resource and Environmental Management College of Tropical Agriculture and Human Resources University of Hawaii at Manoa •We generated a simple economic model that was fun to play with and I came to some interesting projections. •We gathered information from farmers which was very interesting to me. •I therefore told Clyde, why don’t we have a workshop? A little out of hand. We thought that aquaponics might be good for island ecosystems because it is 6 times more productive per unit area of land, uses on 2% of the water as traditional agriculture and releases no effluent into the environment . It is nonpolluting. We just got back from Samoa. E-mail hako@hawaii.edu for how to manual. We worked on a very simple system. Plywood sheet with walls, tub for fish, air pump, bucket. Shown. Both the Ako approach and the Fox/Tamaru approach are highly technical What we did: Economics determined by materials cost to build an 8 plywood system and cost of operations This report is based on real numbers and very modest extrapolation. Recorded the price of the wood, every brick, PVC pipe etc. Labor not accounted for. Items Lettuce Life traya 1 plywood 10 $130 Shade structure 10 $60 Fish tank 10 $80 Air pump 5 $80 Laborb $0? Total $350 aincludes •Cost of each component of each item. •Lifetime of each item. •Costs 3.5 X higher for pre-made systems or another kind of system wood, screws, plastic, polystyrene sheets bbuild yourself; this is not as good an assumption when the system is large. Items Life 1 12 plywood plywood= racewaya 5 raceways Lettuce tray 10 $130 $1,560 $7,800 Shade structure 10 $60 $720 $3,600 Fish tankb 10 $80 $600 $2,600 Air pumpc 5 $80 $220 $1,100 Water pump 5 $310 $1,550 Refrigerators (2)d 10 $1,100 Delivery vane 10 $20,000 Total $350 $3,410 $35,110 Annualized cost $43 $332 $6,260 a4 Annualized costs are costs/lifetime in years feet wide, 100 feet long; see figure b use larger tanks cuse blower for larger operation dvs $8000, chosen for energy conservation reasons ($90/yr vs $4300/yr) edoes a farm this size need a van? •Build yourself 1 plywood 12 plywood= raceway 5 raceways Fingerlingsa $15 $180 $900 Feed $27 $324 $1,620 Electricityb $66 $788 $3,942 $0.56 $6.69 $34 Suppliesc $20 $239 $1,200 Interest $35 $341 $1,815 Labord owner owner owner $74 $434 $1,774 $9,045 Water Lease rent Total variable costs amost $148 of us grow our own; costs are nursery costs bat $0.30/kwh; cOasis cubes mostly; dfor the 1 plywood or backyard system, approx. 2 hr/wk; for the 1 raceway 5-10 hr/wk; 5 raceway, approx 20 hr/wk 1 12 plywood plywood = raceway Lettucea 211 (7.4 ) tilapiab 43 (0.83) 5 raceway 2,534 (89) 12,672 (443) 515 (10) 2,574 (50) Farmers can be more or less productive These values predict sizes of niche markets that can be serviced. a from mediocre season like Spring; 250 g/head bmarket size= l 1b http://img.alibaba.com/photo/11697156/Tilapia_Fillet_Light_Skinned_CO_Treated.jpg Choose the production volume you would like to do. This in most cases determines the markets you can compete in and the prices you can get. A common error is to produce without thinking about the market. 1 12 plywood = 5 raceway plywood raceway Lettucea 211 (7.4 ) 43 (0.83) tilapiab 2,534 (89) 12,672 (443) 515 (10) 2,574 (50) •Our production numbers say 7.4 heads of lettuce or other vegetable per week. Maybe 1 fish/wk. Is this enough for a family? •You save by not having to go to the supermarket. Prices, retail, $5.60/lb for lettuce and $9/lb for live fish. Annual capital cost Annual variable cost $ 43 $ 148 Value of lettuce $ 1,183 Value of fish $ 386 Net profit $ 1,378 Thus, based on the model a backyarder could save about $1,400 a year at the grocery store. Pays for this system in a few months (there are more expensive systems). Or just like the idea of being self-sufficient? 1 12 plywood = 5 raceway plywood raceway Lettucea 211 (7.4 ) tilapiab 43 (0.83) 2,534 (89) 12,672 (443) 515 (10) 2,574 (50) •Our production numbers say 44 heads of lettuce a week. Enough for farmers’ market? Five fish a week. •Prices, retail, $5.60/lb for lettuce and $9/lb for live fish. •Will have to rent stall, go to farmers’ market, deal with food safety issues etc. Annual capital cost Annual variable cost $166 $887 Value of lettuce $7,096 Value of fish $2,317 Net profit $8,360 Thus, based on the model a farmers’ market person could earn about $8,000 a year. Decide for yourself whether it is worth it. Now Janet and her husband, Ray, have cultivated a small business — with a big customer following — selling lettuce and other greens at Manoa Marketplace’s open-air market…. The bags range from $2 to $6, depending on the size…. 1 12 plywood = 5 raceway plywood raceway Lettucea 211 (7.4 ) tilapiab 43 (0.83) 2,534 (89) 12,672 (443) 515 (10) 2,574 (50) •Our production numbers say 443 heads of lettuce per week. Is this enough for small specialty store? And 50 fish/week. •Prices they say are $3/lb for lettuce and $6/lb for live fish. •Capital costs for pre-made or other systems are 3-4 times higher than ours. Annual capital cost Annual variable cost Value of lettuce $2,080 $9,045 Thus, based on the model a small farmer could earn $42,000 a year if all goes well. $38,016 Value of fish $15,444 Net profit $42,335 Premature conclusion. You can make money but won’t become a millionaire. 1 12 plywood = 5 raceway plywood raceway Lettucea 211 (7.4 ) tilapiab 43 (0.83) 2,534 (89) 12,672 (443) 515 (10) 2,574 (50) •Our production numbers say 506 heads of lettuce per day. Is this enough for a discount supermarket? The 400 fish a week would probably overwhelm the live fish market. •Prices might be $2.25/lb for lettuce and $6/lb for live fish (though this high price may become unlikely). Annual capital cost Annual variable cost $50,080 $72,357 $228,096 Value of lettuce Value of fish $123,552 Net profit $229,211 Cost of labor would have to come out of profit. We estimate 4-6 workers. The farmer would be profitable if he or she did everything right. 1 12 plywood = 5 raceway plywood raceway Lettucea 211 (7.4 ) tilapiab 43 (0.83) 2,534 (89) 12,672 (443) 515 (10) 2,574 (50) •Our production numbers say 506 heads of lettuce per day. Is this enough for a discount supermarket? The 400 fish a week would probably overwhelm the live fish market. •Prices might be $1.25/lb for lettuce and $6/lb for live fish (though this high price may become unlikely). Annual capital cost Annual variable cost $50,080 $72,357 $126,720 Value of lettuce Value of fish $123,552 Net profit $127,835 Cost of labor would have to come out of profit. We estimate 4-6 workers. Six workers would make the business unprofitable. We developed a preliminary economic model Working with the model was fun It predicted profitability if there is technical excellence and imaginative niche marketing We can comfortably recommend aquaponics on these bases. A person can make money but will not become a millionaire I enjoyed learning a little economics I especially enjoyed learning from the farmers CTSA seed money grant Western Sustainable Agriculture Research and Education CTSA Pacific Island grant