Company Profile - liberoworld.com

advertisement

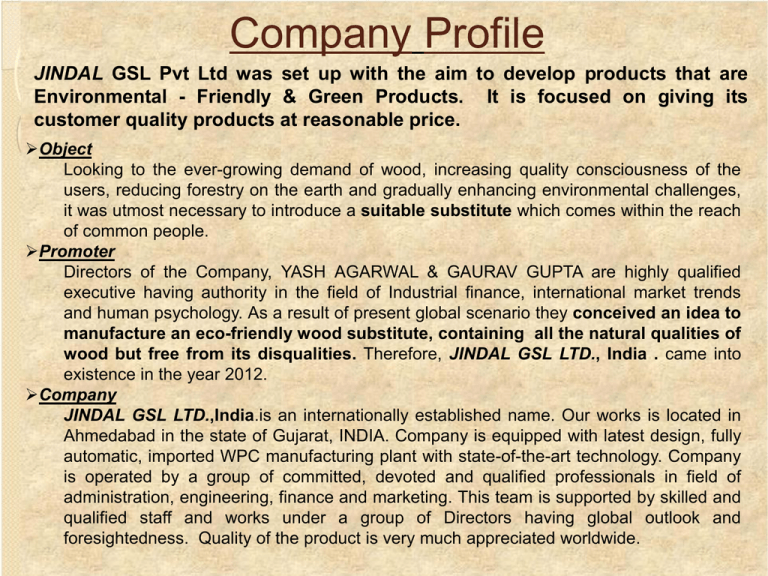

Company Profile JINDAL GSL Pvt Ltd was set up with the aim to develop products that are Environmental - Friendly & Green Products. It is focused on giving its customer quality products at reasonable price. Object Looking to the ever-growing demand of wood, increasing quality consciousness of the users, reducing forestry on the earth and gradually enhancing environmental challenges, it was utmost necessary to introduce a suitable substitute which comes within the reach of common people. Promoter Directors of the Company, YASH AGARWAL & GAURAV GUPTA are highly qualified executive having authority in the field of Industrial finance, international market trends and human psychology. As a result of present global scenario they conceived an idea to manufacture an eco-friendly wood substitute, containing all the natural qualities of wood but free from its disqualities. Therefore, JINDAL GSL LTD., India . came into existence in the year 2012. Company JINDAL GSL LTD.,India.is an internationally established name. Our works is located in Ahmedabad in the state of Gujarat, INDIA. Company is equipped with latest design, fully automatic, imported WPC manufacturing plant with state-of-the-art technology. Company is operated by a group of committed, devoted and qualified professionals in field of administration, engineering, finance and marketing. This team is supported by skilled and qualified staff and works under a group of Directors having global outlook and foresightedness. Quality of the product is very much appreciated worldwide. Trusted by some of the biggest names in the PVC /WPC Foamed Board Industry from deep within……………… Do not follow the path where the path may lead Go instead where there is no path and leave a trail. Set your Goals High & Don’t stop till you get there. INTRODUCTION We would like to introduce ourselves as one of the leading manufacturers of Smart boards which are an alternative to traditional plywood for the first time in India. We are also manufacturing PVC Foam sheets, PVC profiles like Door frames and Flooring and lastly PVC PIPES. Our smart boards can be used for manufacturing Partitions, Modular Kitchen cabinets, shutters, Tables, Wardrobes, Industrial sections, Furniture especially for bathrooms, Wall paneling, false ceilings, prefabricated houses and for the same we have our customers spread across India. Our products have multidimensional characteristics like Anti corrosive and rotting, anti-termite, anti-borer, anti-aging, Fireproof, waterproof, quick and easy to install, easy to clean, high impact strength, maintenance free, easy thermoforming, easy to cut route and fasten, Aesthetic value is high as it has superior finish on both sides which makes it easier to Laminate and print, and lastly it has very good insulation properties. It’s also an ECO FRIENDLY & GREEN PRODUCT as we use a lot of recycled plastics in the same which helps save trees. INTRODUCTION LIBERO Smart Board is an excellent material of construction possessing high strength, stiffness, impact resistance, gain in strength with age, durability, and mouldability. As it has no shape in its plastic stage, it requires to be moulded into various forms using formwork, which consists of the mould in contact with the concrete, the structural supports, and hardware. Among the most commonly used materials for formwork are timber, plywood, and steel plates. WHY YOU SHOULD USE LIBERO SMART WOOD CONSTRUCTION BOARD Shuttering plywood Libero smart wood CONSTRUCTION BOARD Moisture Effect No Moisture Effect No Water Proof Water Proof Fungal Anti Fungal Bacterial Anti Bacterial Wood use for Fixing Limited No wood required for Fixing Warping No Warping Thrown After use Recyclable After use No Saving on Environment Totally green product Termite Effect No Termite Effect Limited Repetitions More Repetitions Not Recyclable Recyclable Heavy Weight Light Weight & Easy to handle Moisture Resistance Waterproof Water absorptive Rot Resistance Antisepsis Rot except special treating Split Resistance Distortion Resistance Cracked by weathering effe ct Distorting effected by chan Almost no Contraction / ge of moisture and tempera expansion ture No Cracked UV Resistance High grade UV resistance Easily effected by UV Fading Resistance Almost No Easy to fade Outdoor adaptability Great Only few of treatedwood adaptive No need Painting No need Need paint periodically Durable/Longevity 50 years <3 years Various Configuration extruded via various moul d simplex Environment Effect Recyclable 100% Consume woods CHARACTERISTICS OF A GOOD FORMWORK PANEL • • • • • • • • • • • Formwork is a temporary means of supporting and protecting fresh concrete during casting and hardening to give the resultant concrete structure a good surface, in the required shape and size. A formwork panel must meet the following functional requirements Formation of a structure with the desired dimensional accuracy, surface finish, strength and durability. Protection of the fresh concrete from damages. Prevention of deformation to the structure from external pressures. Retention of the fine constituents of the concrete till it hardens. Ensuring hardening of the concrete without disturbance. Protection of the concrete from excessive heat and cold. Re-usability. Libero range of Construction boards are exceptionally durable. It is, however, necessary to take adequate care during storage and use, to derive the maximum advantage from its use. A few important guidelines are given below : Unload the panel carefully, lifting a few sheets at a time rather than sliding one over another. Stack sheets on a flat, level and raised surface in a clean, dry and covered place with free circulation of air. Protect the sheets from strong sunlight and prolonged rainfall. CHARACTERISTICS OF A GOOD FORMWORK PANEL • • • • • • • • • • Avoid damage to corners and faces during handling. Do not drop the panels nor drag them one over another. When cut to smaller panels, seal the edges with synthetic paint or varnish. When cut by a handsaw, use fine toothed cross cut saws. Do not use coarse ripsaws. While framing, employ rear fixing with screws as far as possible. Avoid nailing through the face of the plywood. Where, however, this is done, fill the holes or cracks, if any, with a putty. Do not use very long nails, or too many nails. Cover the formwork after erection to prevent contamination of the face by rust from reinforcement or dirt. In case cleaning the face becomes necessary, use an air hose. Do not use a water hose. While poring concrete, use a moveable baffle to protect the form face. Do not strike the forms with metal crowbars, etc., during stripping. Use wooden wedges. Strip the formwork as soon as the concrete has gained sufficient strength to resist damage. Clean all the panels thoroughly after each use with a rag dipped in water. Do not use metal scrapers or wire brushes. Do not allow the panels to dry too rapidly after cleaning. Repair any damage to the surface film by applying three coats of synthetic varnish, after the surface is thoroughly cleaned and dried. If there are nail holes to be filled, fill them with wooden plugs or with putty. After cleaning and repair, stack the used panels on level supports, off the ground, under cover. Stack framed panels face-to-face and back-to-back, alternatively. DISADVANTAGES OF SHUTTERING PLY • • • • Plywood has a cross laminated construction and therefore it has to be cut using fine toothed cross cut saws to avoid chipping off. Most carpenters are aware of this. However, some times for reasons not known to us people do use coarse rip saws, which are normally used to cut timber planks along the grains, to cut plywood into small sizes. This results in producing heavy chipping off of the face veneers on the bottom side. Some times this is mistaken for delamination. Delamination is a clean separation of one veneer from another without any damage to the wood fibers. In the case of chipping off it will be found that the face veneer does show good adhesion and that is why it tends to “splinter” or “chip”. Deterioration Of The Surface Some times the plywood panels after some use will show surface “checks” and discoloration on the face exposed to the concrete and will give the impression that the plywood got “aged”. Such checking and discolorations take place when the plywood face is exposed to sun and allowed to dry rapidly after wetting. When a wet plywood is exposed to sun, the face veneer drys up rapidly and tends to shrink, while the core restrains the shrinkage causing the face to get stretched developing hair line cracks. Besides, the ultraviolet rays in the sun causes discoloration which is very typical of wood. Once the plywood face gets severely checked it has lost its original compactness, smoothness and hardness and therefore its reusability will be severely affected. For this reason users are advised not to allow the panels to dry too rapidly after stripping and cleaning. DISADVANTAGES OF SHUTTERING PLY • • • • • • Libero Construction board has a surface made of rigid film. It cannot surpass the limitations of the wood. It can be cut and scratched by sharp objects. Any such physical damage to the surface sets off a gradual erosion of the fibres eventually reducing the number of reuses. It is like a fabric which gets torn at some place tending to wear off with every wash. When not torn or cut the same fabric withstands normal use and washing for a long time. The site practices recommended by us are all aimed at giving maximum possible protection to the plywood face with a view to help the customer get the highest possible number of reuses. Damages Caused By Nailing And Denailing In some cases the core layers in a plywood will show signs of separation very close to the edges. This can be attributed to what may be called “Cycles of Nailing and Denailing”. Such a plywood might have been nailed to a wooden frame and then denailed, and again nailed on some other frame and so on for a few cycles. During these cycles of nailing and denailing, the impacts produced by hammering tend to damage not only the edges and corners of the plywood but also the bonding between the plies in the misused area. When such a plywood gets soaked in water the edges and corners swell exposing the damaged bonding line and showing signs of core veneer separation. Precautions Carefully fix and remove plywood for maximum reuse Apply releasing agents or mould oils occasionally for easy removal of plywood LIBERO CONSTRUCTION BOARD & ITS SALIENT FEATURES ARE: • • • • • • • • • • • BOILING WATER PROOF FOR LIFE Libero Plastic Ply is ideally suited for bathroom and kitchen furniture which are in constant contact with moisture. The best available plywood is resistant to boiling water only upto 72 hrs. GUARANTEED AGAINST TERMITE ATTACK BUY BACK SCHEME Libero Plastic Ply is ideally suited for wall panelling as termites will first attack the material which is in immediate contact with the wall. Even the most expensive plywood is susceptible to termites and no plywood manufacturer offers any better remedy than pest control. Libero Construction Board can be buy back by the company as per our policy the only company which give this advantage to the buyer. SYNTHETIC NO WOOD BORER Libero Construction Board is ideally suited to replace plywood in showrooms & shop where wood borer can damage stored goods and also result in time consuming rennovation and stoppage of business. FLAME RETARDENT AND SELF EXTINGUISHING Libero Construction Board is self extinguishing whereas plywood burns. Libero Construction Board is classified as Class-I Material as per BS - 476 part 7, flame spread test and retards the fire from one room to the other. Thanks to these superior features Libero construction board offers to builders and contractors the highest rate of reusability and overall economy. USE OF LIBERO CONSTRUCTION BOARD • • • • • • • • • • • • Nailing Libero Construction Board is an excellent material for nailing in contrast to other wood replacements as MDF , cement bonded particle board . Nails can be used a few mm from the edge without cracking the sheet. Nails can be easily fixed on the face or the edges as required. Sawing and Cutting Libero Construction Board can be sawed using ordinary short wood working hand saws with fine teeth. Jig saws and circular saws can also be used. Sheet upto 6mm thickness can be easily cut with a blade or stanley knife. Heat Bending One of Libero Construction Board many advantages in that it is easy to bend when heat is applied locally. A uniform temperature of 115°C to 130° C over the area to be bent gives best results. For right angle bends a 'V' - groove cut along the inside of the bend is helpful . It is vital that the piece which has been bent remains held in place until it has cooled . Screwing and Drilling Screws can be fixed in Libero Construction Board on face and edges. Similar to wood th screw holding capacity of Libero Plastic Ply is excellent but to get best results fully threaded screws are best suited . For external joints provision should be made for expansion by making the hole larger to the screw shaft dia' and large disc washers should be used to cover holes to ensure adequte load distribution. It can be easily drilled with usual spiral metal bits. No bit sharpening procedure is required. Adhesive Bonding As Libero Construction Board is water -based adhesives, FEVICAL-SH are not suitable. Solvent based adhesive like PIDIVYL CP - 291 or fevicol SR 998 can be used for bonding purpose. COMMERCIAL DIFFERENCES Film Faced Shuttering Ply ( FFSP) Libero Construction Boards/ Ply (LCB) Rs. 65 + Freight + Tax Rs. 98 + Freight + Tax Repetition – Maximum 10 Times Minimum 30 Times No Buy Back Offer Buy Back Offer: Rs. 25 per kg. Further Plastering Required Rs. 25 p.s.f. No Plastering Required Rs. 5 Discarding charges of used ply. Buy Back with Freight. Film Face Shuttering Ply ( FFSP) Libero construction board / ply (LCB) Price: 65/- kg Price : 116/- rs kg (98/-sq ft+32 sq ft/Board/27kg per board= Buy Back: NIL 116/ rs -kg) Repetition : 6.5/- kg per repetition ( According to Buy Back : 27/- rs kg = 89/ rs-kg 10 repetitions) Repetition : 2.96/- rs kg per repetition ( According to 30 repetitions) can be more. If you are constructing 10,00,000 sq. ft. you save as below: A) FFSP:6.5/LCB : 2.96/Saving : 3.54/-*10,00,000 sq. ft. = INR 34.5 Lacs. B) Plastering Saving if LIBERO Construction Boar / Ply used: 25/- sq.ft. *10,00,000 sq ft= INR 250 Lacs Saving s= INR 2.50 Crores Total Saving : A+ B= 2.85 INR crores TEST EXPERIMENTED WITH BUILDERS & CONTRACTORS • GUNDECHA BUILDERS (GUNDECHA ZENITH SITE AT MULUND) • NEHA CONSTRUCTION ( SITE OF THAKUR COLLEGE KANDIVLI) • MORWAL BROTHERS ( FACTORY SHED AT DAMAN) • K.K.ENTERPRISES (SAI TOWERS GHATKOPER) • CONSTRUCTION COMBINE ( D.B.REALTY DAHISAR) • HOTEL HILTON ( AHMEDABAD) • SWAROOP CONSTRUCTION SNEHASADAN SOCIETY (REDEVELOPMENT PROJECT GHATKOPAR)