Drill Press PPT

advertisement

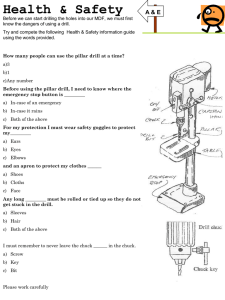

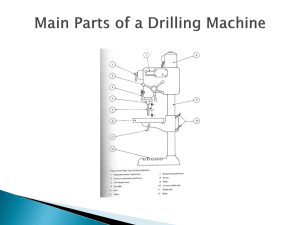

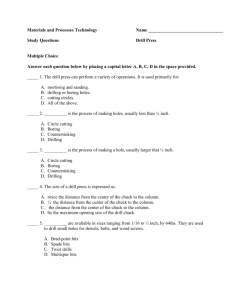

Drill Press General Safety Wear your safety glasses at all times Take off all jewelry Do not wear loose clothing Make sure you are the only person in the safety zone when operating the Drill Press. General Safety continued Keep your material tight against the table Clear scrap or cut material with a brush, other scrap material, or your project from the table. Do not use your hands. Use wood screw clamps to tighten the material to the drill press table Components of the Drill Press Table Chuck Chuck Key Depth Stop Operations of the Drill Press Drilling Boring Countersinking Sanding Routing Table The table should be 90 degrees Chuck Chuck Key Used to tighten the bit or drum in the chuck Depth Stop Drilling Drilling is defined as creating a hole completely through the thickness of the material. Boring Boring is defined as creating a circular pocket a specific depth in the material. Countersinking Countersinking is defined as creating a hole completely through the thickness of the material with a taper on the surface to accommodate the taper head of a screw Sanding Sanding can be done on the drill press with the sanding drum bit. Routing Routing a decorative edge or a wood joint can be done on the drill press. Operation Procedure 1 1. Tighten the bit or drum in the chuck with the chuck key. Operation Procedure 2 2. Remove the chuck key!! Operation Procedure 3 Adjust the table to be 90 degrees to the bit or drum Operation Procedure 4 Use a back-up board to prevent drilling into the table. Operation Procedure 5 Line up your material with the mark needed to be drilled Operation Procedure 6 Clamp the material down to the table with wood screw clamps. Operation Procedure 7 Turn the machine on and drill or bore the hole needed. Use a consistent rocking motion to clear chips from the hole Tighten the bit Adjust the table Backup Board Line up the center mark Clamp the material Drill or Bore the hole