here - Summerhill College

Drilling

There are three types of Drilling machine used in the

Engineering room:

1. Bench Drills

2. Pillar Drills

3. Hand drills

1. Bench Drills

• Used for drilling holes through woods, plastics and metals.

• It is normally bolted to a bench so that it cannot be pushed over

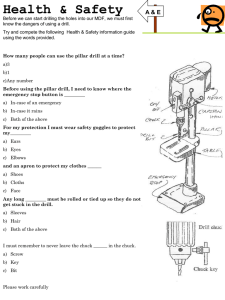

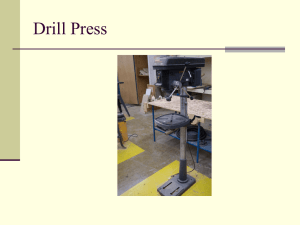

2. Pillar Drills

• The Pillar drill is a larger version of the bench drill

• This has a long column which stands on the floor

• Because of its larger size it is able to drill larger pieces of materials and produce larger holes.

3 Hand drills

• These can be either electric, battery or hand operated

• There is a limit to the size drill bit that can be used

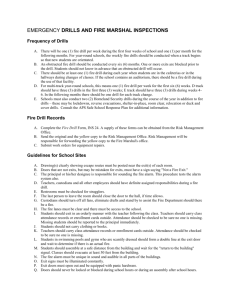

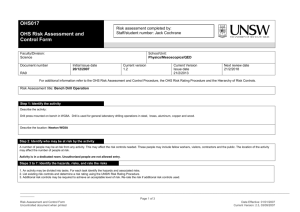

4. Safety on the drilling machine

• Follow all teacher instructions carefully.

•

Always wear safety goggles

• Ensure the centre punch mark is under the drill bit

•

Clamp the materials down or use a machine vice.

• Never hold materials by hand while drilling.

•

Always allow the chippings or swarf to clear the drill by drilling a small amount at a time.

•

Reduce pressure when the drill bit is breaking through

Using the pillar or Bench drill

When Drilling, the piece must be held firmly using the following ways: a) Machine Vice b) Clamping directly to the table c) Vice grips etc.

Drill bits

• Twist drills are made from High Speed Steel

• Smaller drill bits have parallel shanks, larger bits have taper shanks