Drilling and Reaming

advertisement

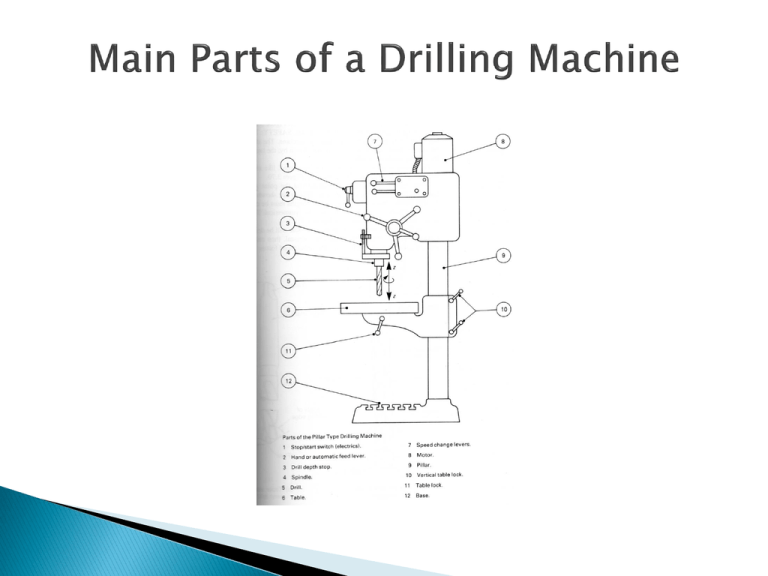

Parallel shank drills as the name suggests have a parallel shank and are held in the drilling machine using a three jaw self centring chuck. These types of drill range from 0.5mm to 13mm diameter in 0.5mm increments as standard. Sizes in between at 0.1mm increments are available for tapping dills and special applications but are more expensive. The chuck is fixed in to the spindle of the machine using a Morse taper. When fitting drills in to the chuck it is essential that the chuck only grips on the shank of the drill and the correct chuck key is used Drills larger than 13mm diameter are manufactured with a taper shank as seen opposite. These types of drills are fitted directly in to the spindle of the drilling machine as opposed to in a chuck. The drill is held in place by means of friction between the taper on the shank and the taper in the spindle. This means much larger drills can be used without the risk of them slipping due to the larger area in contact with the machine. The tang on the top is purely to remove the drill from the machine not to secure it in place. Taper shank drills are available as standard in 0.5 mm increments up to around 50mm diameter. The tapered shank (Morse Taper) on the drill is available in a range of sizes depending on drill size these being MT1, MT2, MT3 and MT4. The Taper in the spindle of drilling machines also varies depending on the size of the machine usually MT2, MT3, MT4 or MT5. To enable fitting of different size drills in different machines Morse Taper Sleeves and Adaptors are available, these come in various sizes e.g. MT1-MT2, MT2-MT3 etc. Allowing you to step up or down depending on the spindle size and the drill being used. To fit the chuck or taper shank drill in to the machine the taper is inserted into the spindle with the tang rotated to line up with the slot as shown opposite. The drill is then secured into the spindle using one of the following methods. Tapping the drill into the spindle lightly using a soft faced mallet Placing a piece of wood on the table and rotating the spindle handle until the drill lowers and touches the wood then applying light pressure to push the drill securely into place. In both cases only minimal force is required as the power is transmitted by friction between the two tapered components. To remove the taper shank drill or chuck, the spindle is rotated by hand until the slot lines up with the slot on side casing. A drill drift is then inserted into the slot and tapped with a hammer as shown. This ejects the drill from the machine and the drill drift can then be removed. When ejecting the drill or chuck from the machine it is essential to hold it at the same time to prevent it falling on the floor which can cause damage. It is important that the angle point and the length of the of the cutting edges (lips) are ground accurately and equally to avoid problems when drilling holes. This can be checked when sharpening using a drill angle gauge as shown opposite If the angles are different it can cause the drill to chatter and drill a hole that is out of shape, a bit like a 50p piece. If the edges are of different lengths it can cause hole to be drilled over size as shown. When drilling holes it is essential the location is accurate, to achieve this we start the hole using a centre drill. Due to its small point the centre drill can be located accurately in the centre punch mark; also it provides a good lead for the correct size drill When drilling larger holes it is necessary to use a pilot drill to remove some of the material first. Trying to take too much material out at once will make the process more difficult, and may cause damage due to overheating of the drill and material When several items are to be assembled together Countersink screws or cap head screws, are often used and these need to sit down flush with the component. To achieve this we use countersinks bits top right or counter boring drills bottom right. When counter boring you need to ensure that the pilot hole is the correct size for the shank of the tool. When using these tools it is essential that the speed of the drill is slowed down or the tool will overheat and become blunt very quickly. Drilling holes is reasonably accurate but some holes need to be perfect or have a much better surface finish than that achieved by drilling. To achieve this a Reamer is used. Reamers are of similar shape to drills but have more flutes and no point, they also run slower, around a third of the speed of drills. Reamers come with either a spiral flute or a straight flute as shown, they also come in hand version or machine versions Hand Reamer Machine Reamer Machine reamers are used in the same way as drills by inserting them in a drilling machine as shown Using a Machine Reamer Hand reamers are used by placing them in a tap wrench as shown and rotating them by hand When reaming a hole you need to drill a pilot hole roughly half a millimetre smaller than the finished size and then open it up using the reamer. Using a Hand Reamer