File

advertisement

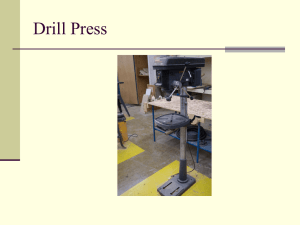

Materials and Processes Technology Name _________________________________ Study Questions Drill Press Multiple Choice Answer each question below by placing a capital letter A, B, C, D in the space provided. _____ 1. The drill press can perform a variety of operations. It is used primarily for: A. B. C. D. mortising and sanding. drilling or boring holes. cutting circles. All of the above. _____ 2. __________ is the process of making holes, usually less than ¼ inch. A. B. C. D. Circle cutting Boring Countersinking Drilling _____ 3. __________ is the process of making a hole, usually larger that ¼ inch. A. B. C. D. Circle cutting Boring Countersinking Drilling _____ 4. The size of a drill press is expressed as: A. B. C. D. twice the distance from the center of the chuck to the column. ½ the distance from the center of the chuck to the column. the distance from the center of the chuck to the column. by the maximum opening size of the drill chuck. _____ 5. __________ are available in sizes ranging from 1/16 to ½ inch, by 64ths. They are used to drill small holes for dowels, bolts, and wood screws. A. B. C. D. Brad-point bits Spade bits Twist drills Multispur bits _____ 6. __________ are used to cut perfectly round, flat bottom holes. A. B. C. D. Brad-point bits Spade bits Twist drills Multispur bits _____ 7. __________ come in diameters from ¼ to 1- ½ inches. These are fast –cutting tools that leave a rather rough hole. A. B. C. D. Brad-point bits Spade bits Twist drills Multispur bits _____ 8. __________ are ideal for drilling wood. These come in sizes from 1/8 to ½ inch by 16ths. The sharp brad point allows you to place the hole exactly where you want it. The sharp cutting spurs make a clean hole in the wood. A. B. C. D. Brad-point bits Spade bits Twist drills Multispur bits _____ 9. __________ are used to cut flat bottom holes, even through knots, end grain, and veneer. A. B. C. D. Countersink bits Plug cutters Circle cutters Forstner bits _____ 10. __________ are cone-shaped bits used to enlarge the top of a hole so that a flathead screw can be driven flush with the surface. Sizes range from ¼ to ¾ inch in diameter. A. B. C. D. Countersink bits Plug cutters Circle cutters Forstner bits _____ 11. __________ also called a fly cutter, can be adjusted to cut holes from 1 to 4 inches in diameter. A. B. C. D. Countersink bits Plug cutters Circle cutters Forstner bits _____ 12. __________ are used for cutting cross-grain and end –grain plugs and dowels up to 3 inches long. They come in the common sizes of 3/8, ½, 5/8, ¾, and 1 inch. The smaller sizes match the diameter of dowel rods. A. B. C. D. Countersink bits Plug cutters Circle cutters Forstner bits _____ 13. When installing a drill bit, use the __________ key to tighten the bit securely. Remember to always remove the __________ key from the chuck when finished A. church B. cluck C. chuck D. charlie . _____ 14. On most drill presses, the speed ranges between 250 and 3,100 rpm. Typical, the __________ the hole being cut, the lower the spindle speed. A. B. C. D. smaller larger faster slower _____ 15. To control the rotation speed of the spindle, a drill press is equipped with either steppulleys or a variable speed control. Our drill press is equipped with step pulleys. The __________ is the only person in the lab who may change the spindle speed on our drill press. A. B. C. D. student maintenance worker instructor Anyone can change the spindle speed. _____ 16. The __________ is on the right side of the drill press. It controls how far down the drill bit or cutting tool can move. A. B. C. D. depth gauge height gauge stop A and C To safely drill or bore holes, place the following steps in the correct order: _____ 17. Step 1 A. Place the work piece on the drill press table over a piece of scrap wood. _____ 18. Step 2 B. If the stock is hardwood or the hole is deep, back up the bit once or twice to remove the chips before finishing the hole. _____ 19. Step 3 C. Finish drilling the hole. Always drill completely through the stock and into the scrap wood _____ 20. Step 4 D. Turn on the power and slowly move the point of the bit into the stock. Hold the stock firmly and apply even pressure to the handle. _____ 21. Step 5 E. Locate the center of the hole on the work piece and mark it with a center punch or awl. True (A) or False (B) Answer each question below by placing a capital letter T for true or F for false in the space provided. _____ 22. Wear eye production only when boring holes. _____ 23. Use a drill bit with a straight shank – never a square one. _____ 24. Check the speed. Use a faster speed for large holes and a slower speed for small holes. _____ 25. Clamp work securely, especially when operating the drill press at high speeds or boring or cutting large diameter holes. _____ 26. Keep your hair and loose clothing away from all moving parts. _____ 27. Never remove the chuck key before starting the machine. It must be in place for the drill press to operate. _____ 28. Clamp round or cylindrical stock in a vise before drilling. _____ 29. Keep your fingers at least 2 inches away from the rotating cutting tool. _____ 30. Remove chips and shavings with a brush or a stick of wood; never use your hand or fingers. _____ 31. Feed the drill or bit smoothly into the work piece. When the hole is deep, withdraw it often to clear the shavings. Matching – Parts of the Drill Press _____ 32. Column D E _____ 33. Tilting Table _____ 34. Chuck B _____ 35. On/Off Switch _____ 36. Safety Guard for Belt and Pulleys A C