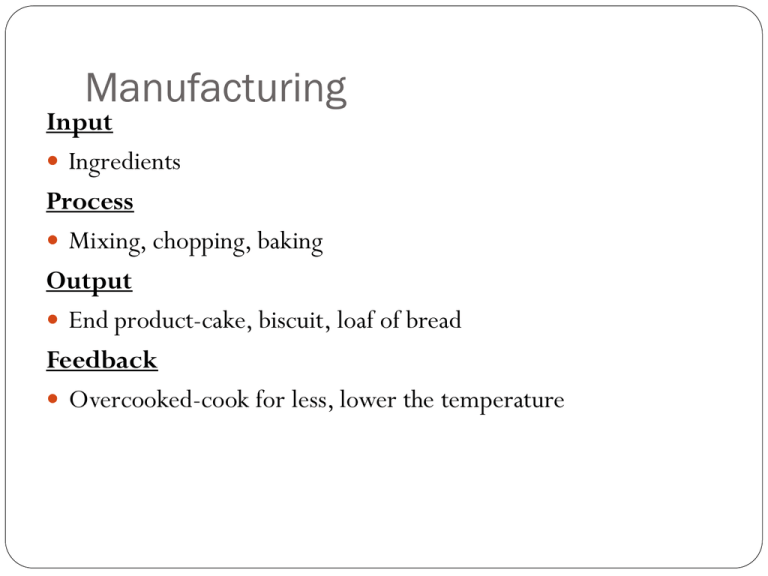

Manufacturing

advertisement

Manufacturing Input Ingredients Process Mixing, chopping, baking Output End product-cake, biscuit, loaf of bread Feedback Overcooked-cook for less, lower the temperature Scales of production Manufacturers decide the scale of production depending on the number of products predicted to be sold and the shelf life. Just in time means that the materials are delivered to the factory just in time to be turned into the products for immediate dispatch to the shops. This means products don’t need to be stored in a factory. This cuts down waste and reduces risk of bacterial contamination. Types of production One off/Jobbing Is used to make specialist products such as cakes for weddings and birthdays. Can be costly Rely on skilled workers Generally don’t require special equipment. Types of production Batch Production Makes a specific quantity on a large scale of the same product such as biscuits or cakes. Usually done by one person or a team. The equipment used can make one or more product and workers need to be skilled. Types of production Continuous flow • This is used to make products which are sold in large quantities and have a high shelf life. They are often made 24 hours a day, seven days a week. Products include baked beans, biscuits, cakes and crisps. Machinery can only be used for that product. CAM is often used in this process. Types of production Automated manufacture • May be included in continuous flow production lines. This method uses computers and helps to increases productivity, is safer for workers, more hygienic, assures final quality, measuring, weighing, cutting, shaping, critical control points are automatically tested. Standard components examples include grated cheese, pizza bases, ready made pastry cases. • Advantages • Disadvantages • Save time • May forget to order and • Can speed up manufacture • Can use a less skilled • • • • • • workforce Less cross contamination Less equipment needed Less effort Ensures consistency of product • • stop production May need special storage arrangements May be more expensive May not be up to standard Same components may be used by other companies. Consistent product A consistent product means producing something the same every time. The use of machinery can help to do this as It can be faster/need less workers Don’t need to be as skilled There is less human error It can be set at a certain speed or for a certain time. Eg using a mixer or electric deep fat fryer It can cut the same thickness.eg using cutters Use of standard components can ensure you get the same standard. Using computers CAD (computer aided design) and CAM (computer aided manufacture) • Advantages of using • • • • • • computers No mistakes Can run all day without a break Save on labour costs Removes human error Can assess 1000s of products in minutes Cab detect things that the human eyes cannot see. Using computers CAD Computer aided design • To design the physical appearance of a product • To calculate the nutritional profile of a product • To model the cost • To calculate the shelf life • To present sensory data like profiles • To model a production procedure • Produce packaging designs Computer aided manufacture Load cells Measure the weight of ingredients and store the info on a computer so it knows when to reorder more. Light refractor Spots changes in colour such as bad crisps or burnt food Light detector Used to check the thickness of sauces. Temperature Takes and records critical temperatures of cooking and storing foods Metal detector Checks food for metal to makes sure safe to go to customer. Using computers CAM Flow charts Flow charts usually have four symbols The terminator (Oval) used at the start or the end Process (Rectangle) What activity needs to be carried out Decision (Diamond) Usually a question with a yes or no answer Arrows which show the flow of the chart Quality assurance and quality control Quality in food is very important. Firstly it means the food is safe to eat and also it satisfies the customers needs. So every time you buy this product as a customer you know it is going to be exactly the same. Quality assurance This simply means a guarantee of quality. Manufacturers assure their customers that the product will be of a consistent quality. The manufacturer does not want to loose this reputation as it may cost sales Quality control These are the checks which are carried out to check the quality of the product. They are done at the designing, manufacturing and end of manufacturing stages Quality control will check Size Shape Appearance Taste texture Tolerance Products need to be within a certain tolerance to be of an acceptable quality. So the size might be measured or the temperature taken. These measurements will need to be within a certain tolerance to be acceptable. So the temperature on these pies will need to be within a few degrees or the whole batch will be throw out, for safety reasons. Pizza may need to be between 21 and 21.5 cm. Or it will not fit in the box. Removing hazards Manufacturers have a legal requirement to make sure their product is safe to eat. When a new product is being designed a HAZARD ANALYSIS must be carried out. This means looking at what could go wrong and making a plan to stop it from happening. Types of hazard Biological Salmonella, listeria, E coli Physical Hair, metal, fish bones Chemical Cleaning materials HACCP Hazard analysis and critical control points To produce a HACCP chart the manufacturer Lists the processes involved in the making of the product. Identifies the areas where risk might happen. Decides which are critical to the safety of the consumer and plans how to reduce these risks using CRITICAL CONTROL POINTS. A check on a cooked food to make sure it has reached the correct temperature may prevent food poisoning in a customer CCPs check the food is safe to eat QCPs check the size and shape of the food for quality