Scratchbuilding HO freight cars getting started Alan Saatkamp MMR

advertisement

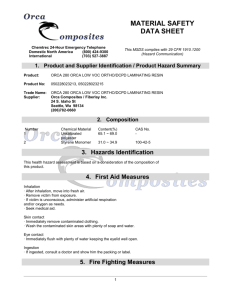

Scratchbuilding HO freight cars getting started by Alan Saatkamp MMR My thanks to Richard Dahl, Brad Hinton, and Matt Saatkamp for the photos they provided Step 1decide what type of car to build considerations: available time current skill set purpose (usable vs. display model?) available prototypes (and images to model) Step 2 gather information including: images, measurements, and data. Railroad Pictures Archives is a great resource for images (note the aggregate load) Step 3 Be sure to obtain permission if visiting a prototype site to do research Take lots of pictures from various angles, as well as car measurements—DAIR Trainmaster Tim Smith gave Australian friend (and photographer) Brad Hinton and me permission to take pictures and measurements of an LGEX 52’ 6” gondola located in Dell Rapids in 2011 Step 3 With a set of good images and measurements, begin collecting materials for the project Step 4 Below: tools for constructing and decorating (plus an airbrush, tap and drill set, and a North West Short Line chopper, not pictured) Step 5 examples of detail parts used in construction— available by ordering from your local hobby store Constructing the model Measure a scale 52’ 6” x 9’6” and cut .040” sheet styrene for the underside of the car. Cut .020” sheet styrene to the same dimensions for the car floor Add Rite Wey thin weights (I purchased through TLR President Gerry Miller in Dubuque) sandwiching them between the layers. Add a .040” x .060” strip frame before gluing the floor and underside together with CA. This causes the interior height of the car to decrease to 4’ vs. the 5’ prototype, which I acknowledged in the narrative write-up for model judging. For side sheets I used scale drawings and cut .040” sheet styrene with 5.5’ scale ends plus the 15” along the center where the fishbelly sides slope for 22’ Build top chords from .060 x .080” strip styrene I used “ears” of Kadee coupler pockets to create the four lift rings. Bottom sills are .020 x .040” strip styrene (abbreviated as “ss” for the rest of narrative) I used dreadnaught commercial ends The various posts are from .030” ss cut with my North West Short Line chopper. I tapered the bottom of certain posts and glued them in place The brake system has Barber S-2 truck mounted brakes and 36” Intermountain wheels. Brass rod models the brake connections per the proto drawing Plano makes the Stanray uncoupling levers which I glued in place with CA after paint and weathering I used strip styrene for the end platforms. The brake chain is from safety chain The end plates are from .030” sheet styrene and decals were used for reporting marks The center sills on the car bottom are from .060” ss Crossbearers are also from ss as are the crossties Bolsters are from strip styrene (layers). I used a tap and drill set to accept the 2-56 screws for the trucks Details West makes the metal cushion draft gear unique to these gondolas Commercial brake hoses and brackets were glued in place Grab irons and ladders are from brass rod and strip styrene. The prototype showed some damaged (bent) which I modeled and carefully described for judging so they didn’t think I was just careless—this has happened to numerous modelers in judging Polly Scale New York Central jade green paint was airbrushed (thanks to Eric Carlson’s equipment). Weathering using roof brown and burnt sienna was applied with a microbrush and tip of a bent paper clip (idea courtesy Bill McKean). The interior is heavily rusted with the same mixture. Black trim film represents the paint on appropriate panels. Decals as described above were applied, with a slight slope in the lettering done intentionally per the prototype and described for judging purposes The car bottom is spray painted fabric tan with a light dusting of tan acrylic chalks, then spray painted with a fixative to protect the chalks before Dullcoting. Highway decal strips cut to .25’ x 1.5’ scale represent the reflective safety tape. Wider tape at the car ends came from another set. Red and white reflective tape came from another decal set. No chalk marks on the cars, since the trainmaster indicated never having seen any on this type of car—noted for the judges. Route boards are heavily weathered with drybrushed brown and grimy black Other detail parts such as ladders, wheel backs, faces, trucks, springs, end caps, brake wheel, AEI (automatic equipment identification) tags, end steps, and couplers were painted with various colors per the prototype, then Dullcoted when complete. The uncoupling levers include white, blue, and grimy black, which I also painted accordingly. The removable load came from pink Sioux quartzite (.25” chips) from the Dell Rapids quarry, glued on sheet styrene painted the interior color (jade green, which should/could have better been rust). Here’s the finished model including a load from actual quartzite chips from Dell Rapids quarry along with an image of the prototype From another angle—note the details including AEI tag, lift rings, stirrup steps, ladders, uncoupling lever, cushion draft gear, grab irons, platform, brake wheel, brake chain, reporting marks, air hose (barely visible), and stirrup steps The truck-mounted brake system prototypical on this car means less brake gear on the underside of the car. Contrast this with the example on the next slide. The CMHX 65’ gon models a prototype at Midwest Railcar Repair. It has a more typical AB brake gear set. Jeff Wilson’s “Detailing Freight Cars” by Kalmbach Publishing has lots of tips on how to build and weather freight cars of any period (ISBN 978-089024-691-7). Also, the Car Builders’ Cyclopedia of American Practice (on-line) has many terms. In summary: Freight car building is an excellent learning process and can add to your freight car roster, plus a chance to work toward an Achievement Program certificate It was difficult to “ruin” an attractive looking jade green gondola with all the necessary weathering, but it did add to the realism based on prototype images The more detail the better appearance and score. This model earned 94 of a possible 125 points, a merit award, and first place for freight car models during Rails to the Rocks in May 2012 Questions?