Littlefield Labs Game Overview: ISQA 511 Presentation

advertisement

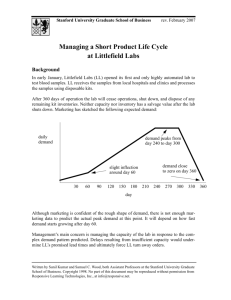

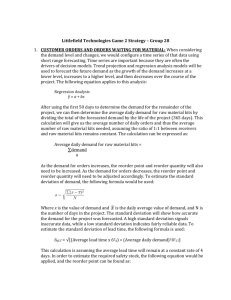

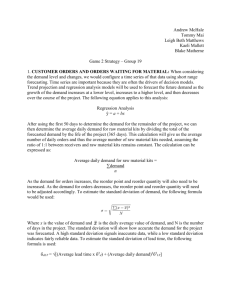

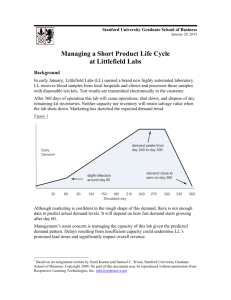

Prof. Mellie Pullman Online Registration & Game Overview ISQA 511 Getting on to the game, come prepared with a credit card, your team name and password (details on their format in next slides) http://lab.responsive.net/lt/pdx/start.html Obtaining Your Access Code Click here Create A New Account Click here Follow step–by–step instructions to purchase your access code Entering Your Course Code cash Enter course code Registering Your Team Enter team name * All lower case letters or numbers * No punctuation or spaces example Registering Your Team Enter team password * All lower case letters or numbers * No punctuation or spaces example Enter student’s names * Caps and spaces are OK * Please NO apostrophes! Hannah Lisker Charlie Wong Shane O’Brien Enter student access codes Hannah Lisker Charlie Wong Shane OBrien akjndk8l slhfg7wk hkjft96l A Brief Overview Your Laboratory: Four steps at three stations 1) Sample Preparing – Step 1 blood is transferred to test tubes in the test kit 2) Testing – Steps 2 & 4 samples are tested and information is recorded 3) Centrifuging – Step 3 plasma and blood cells are isolated Capacity Costs • Station #1 SAMPLE PREPARING MACHINES – $90,000 each • Station #2 TESTING MACHINES – $80,000 each • Station #3 CENTRIFUGING MACHINES – $100,000 each • Resale value for any machine – $10,000 each Factory Process • Every step has its own process time • Littlefield measures average daily utilization rates at each station • Queues hold waiting jobs • The Lab holds a maximum WIP of 100 orders lead time = process time + wait time Orders and Kits • Every arriving customer order is matched with a new test kit – test kits cost $600 each – shipments have a fixed ordering cost = $1,000 – supplier’s lead time is always 4 days • Three criteria to place an order: 1) Inventory on-hand is lower than the reorder point 2) There are no shipments of materials in transit 3) Cash on hand is sufficient for the order quantity Reorder Point – Stocks are replenished when they reach some pre-determined “low point”. • A system commonly used by squirrels • Well, also by you, your checkbook vendor, and many other systems. – – – – – You start with 160 kits in stock Your reorder point ROP is set at 40 kits The order quantity Q is set at 120 You can change both ROP and Q See your inventory chapter for helpful ideas. Contract Pricing Three contracts to choose from < 24 lead hours 1) quoted time==$1000 7 days, max lead time = 14 days, > 72 hours = zero price = $750 2) quoted lead time = 1 day, lead time = 3 days, *max Factory must still price = $1000 (pictured here) purchase inventory 3) quoted lead time = 12 for orders hours, max lead earning time = 24 hours, = $1250! zeroprice revenue An example using Contract 2 ≤ 24 hours = $1000 ≥ 72 hours = zero * Factory must still purchase inventory for orders earning zero revenue ! Logging Into Your Laboratory after the simulator has been initialized Today http://lab.responsive.net/lt/pdx/entry.html Logging Into Your Laboratory Enter team name example Logging Into Your Laboratory Enter team’s password example Explore Your Laboratory Click Box: Customer Order Queue Click “Plot Job Arrivals” and Download Data • Click download button • Save to desktop • Open with MS Excel or another spreadsheet application • Copy > Paste data columns to a master worksheet • Index by Day Opening the data in Excel • You will have 50 days worth of data until it starts running dynamically on Feb. 3 • The demand will increase until around day 150 and then level off • Figure out the demand point where it levels off number of jobs arriving each day day 1 2 2 2 3 1 4 0 5 2 6 1 7 0 8 2 9 2 10 3 11 1 … … 48 6 49 9 50 6 Forecasting Demand (arrival rate of jobs) • • • • Overall Linear trend = SLOPE(known_y's,known_x's) = INTERCEPT(known_y's,known_x's) Forecast for the demand at the point where you think it will level out. Look at Capacity Problems (station 1 Queue Box) Click on Station 1 to see Utilization Might want to see what happened Click on Materials Buffer Box to see your inventory policy & status As demand goes up, What could happen here? What can you do? Completed Job data Current Job Lead Time through system & contract information Key Hints • Forecasts estimate future outcomes • They are not known for precision • A prediction interval should be considered Arrival Rate * Process Time Expected Utilization = # of Machines Key Hints • Balance your work stations, reduce bottleneck • Proactive are better than reactive strategies • Monitor your inventory and change ROP and Quantity if you need to. It takes 4 days for part orders to arrive from your supplier so make sure not to run out during lead time. • Watch your completed job lead time/revenue to take most profitable contract when possible Deliverable • No more than 2 written pages (then appendices) which cover your teams experience • What did you do (in sequence)? • Why did you make that decision? • How did it work out? • What did you learn during the process? • Include an Appendix with a “journal” and any relevant calculations.