Littlefield Laboratories_CASE - Responsive Learning Technologies

advertisement

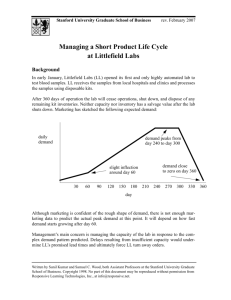

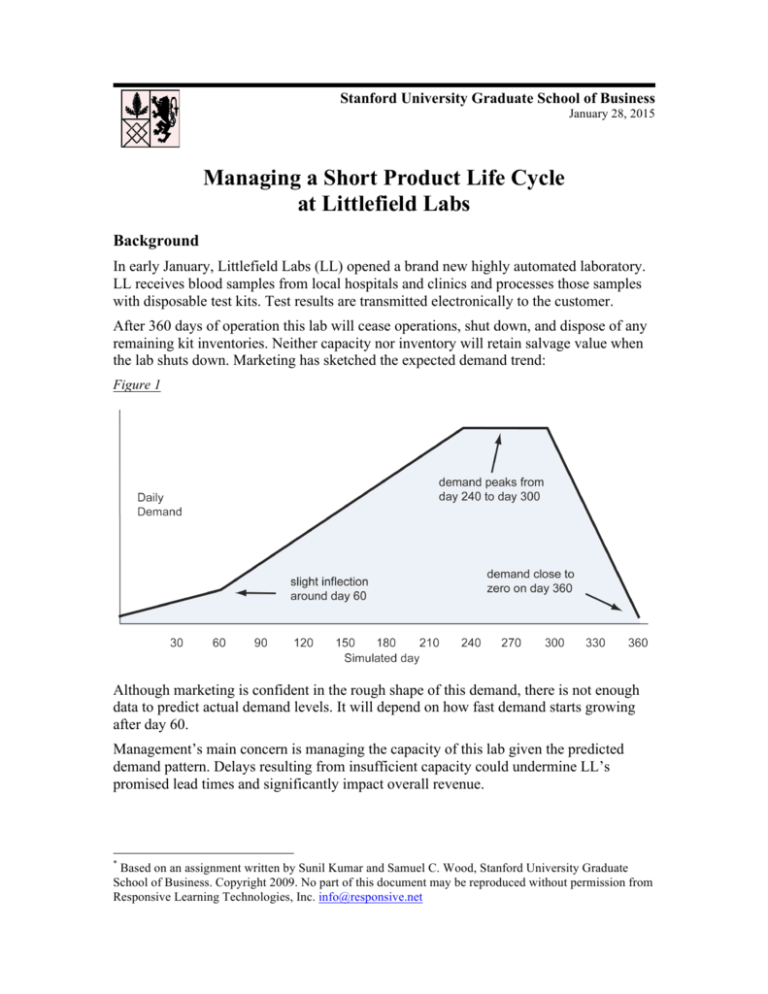

Stanford University Graduate School of Business January 28, 2015 1 * Managing a Short Product Life Cycle at Littlefield Labs Background In early January, Littlefield Labs (LL) opened a brand new highly automated laboratory. LL receives blood samples from local hospitals and clinics and processes those samples with disposable test kits. Test results are transmitted electronically to the customer. After 360 days of operation this lab will cease operations, shut down, and dispose of any remaining kit inventories. Neither capacity nor inventory will retain salvage value when the lab shuts down. Marketing has sketched the expected demand trend: Figure 1 Although marketing is confident in the rough shape of this demand, there is not enough data to predict actual demand levels. It will depend on how fast demand starts growing after day 60. Management’s main concern is managing the capacity of this lab given the predicted demand pattern. Delays resulting from insufficient capacity could undermine LL’s promised lead times and significantly impact overall revenue. * Based on an assignment written by Sunil Kumar and Samuel C. Wood, Stanford University Graduate School of Business. Copyright 2009. No part of this document may be reproduced without permission from Responsive Learning Technologies, Inc. info@responsive.net Operations at Littlefield Labs Littlefield Labs uses one test kit per blood sample and disposes of that kit after processing. LL sends each sample through a reentrant four step process over three machines as shown: Figure 2 The purchase price of each machine is shown above as well. The retirement price of each machine is $10,000—if that machine is retired before day 360. There is one machine at each station when the game begins. Management has performed a stopwatch study for each of the four different process steps. The following table displays their results: Hours Step 1 Step 2 Step 3 Step 4 3.4 0.8 0.4 0.1 There is virtually no variability in a given step’s process time from one job to the next. Earlier steps are longer than later steps, thus: Step 1 is longer than Step 2, which is longer than Step 3, while Step 4 is the shortest. Raw Materials A fresh test kit costs $100. A reliable supplier delivers the exact order quantity two weeks after an order is placed and paid for. Placing an order costs $1000—plus the cost of any kits in that order. Management considers the physical cost of holding inventory to be negligible compared to the opportunity cost of lost interest for money sunk into inventory. Cash earns interest at a rate of 10% per year, compounded daily. LL uses a Reorder Point / Order Quantity materials purchasing policy. That is, raw kits are automatically purchased whenever the following three criteria are met: (1) the inventory of raw kits is less than or equal to the reorder point, (2) there are no orders for raw kits currently outstanding, and (3) the lab has sufficient cash to purchase the reorder quantity. An order is not placed if any one of these three criteria is not met. Managing a Short Product Life Cycle at Littlefield Labs 2 Contracts Customers are willing to pay a premium prices for fast lead times. You have three pricing contracts to choose from: • price $200; quoted lead time 7 days; maximum lead time 14 days. (This is the contract that the lab starts with.) • price $225; quoted lead time 1 day; maximum lead time 7 days. • price $250; quoted lead time 0.25 days; maximum lead time 1 day. If an order’s lead time exceeds the quoted lead time, revenue for that order decreases linearly from the quoted price down to zero once the maximum lead time is surpassed. Contracts are assigned to orders when they arrive at the lab. An order’s contract cannot be subsequently changed. Assignment It is now February and LL has installed a high-powered operations management team (that’s you) to manage the lab’s capacity. For the next 330 simulated days you must buy or sell machines, set inventory policies, and quote lead times to maximize the lab’s overall cash position. You may also change the way testing is scheduled at Station 2. Jobs at the tester are currently scheduled First-In-First-Out (FIFO), but you can give priority status to either the long initial test or the shorter final test. There are 30 days of historic data available for your review. Once the assignment begins, the simulator will run at a rate of 198 simulated days per real day.. There will be a total of 360 simulated days, corresponding to a laboratory life time of one year. Winners are determined by cash balances shown at the end of a simulated year. Deliverables Consult your instructor for details about what your team is supposed to deliver for evaluation and grading. Managing a Short Product Life Cycle at Littlefield Labs 3 Icons on the Littlefield Laboratories web page: ICON Order Queue: INFORMATION AVAILABLE • Number of new customer orders by day • Average number of orders waiting for kits by day • Current pricing contract for arriving orders Materials Buffer: • Average number of kits (raw materials) in the buffer by day • Inventory costs • Reorder Point and Order Quantity • Time until next shipment arrives Station Queues: • Average number of kits in process and waiting while all machines in that station are busy, by day Stations: • Number of machines in each station • Scheduling Policy (tester only) • Historic utilization of the station by day (i.e., the average fraction of time machines were busy at that station during each simulated day) Completed Jobs: • Numbers of orders completed by day (by pricing contract) • Average order lead time by day (by pricing contract) • Average revenue per order by day (by pricing contract) Once the game is running, clicking on some of the above icons will also show an "edit data" button that you use to make changes to your lab. Click on any "Station" to buy or sell machines at that station. Click on "Station 2" to change the scheduling rule at that station. Click on "Materials Buffer" to change the reorder point and order quantity for the raw materials. Click on "Completed Jobs" to change the contract that will be applied to future customer orders. Managing a Short Product Life Cycle at Littlefield Labs 4 Sources and uses of cash can be obtained by clicking on the cash button on the web page. Sources of cash are revenue, money raised from the sale of machines, and interest. Uses of cash are raw material (kit) purchases and the purchase of additional machines. Finally, the overall standing button displays the relative rank of your team during the game. Managing a Short Product Life Cycle at Littlefield Labs 5