Virtual Design | CATIA Mechanical Design

advertisement

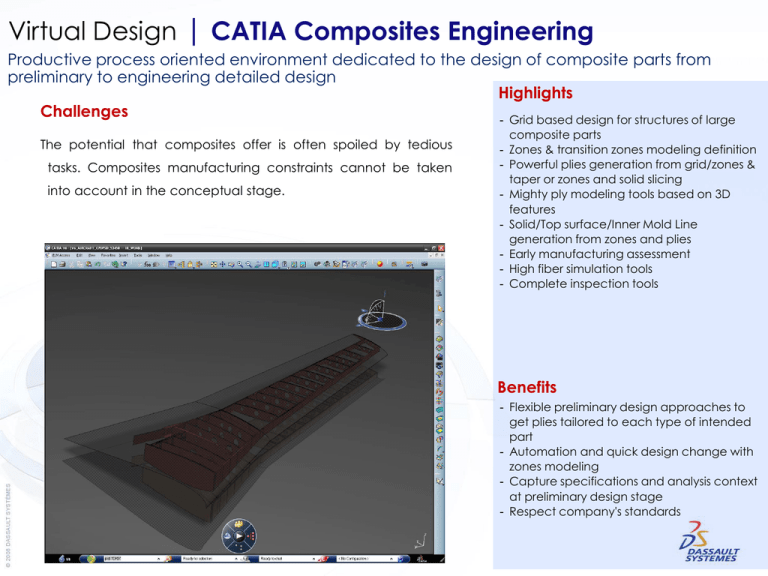

Virtual Design | CATIA Composites Engineering Productive process oriented environment dedicated to the design of composite parts from preliminary to engineering detailed design Highlights Challenges - Grid based design for structures of large The potential that composites offer is often spoiled by tedious tasks. Composites manufacturing constraints cannot be taken - into account in the conceptual stage. - - composite parts Zones & transition zones modeling definition Powerful plies generation from grid/zones & taper or zones and solid slicing Mighty ply modeling tools based on 3D features Solid/Top surface/Inner Mold Line generation from zones and plies Early manufacturing assessment High fiber simulation tools Complete inspection tools Benefits - Flexible preliminary design approaches to get plies tailored to each type of intended part - Automation and quick design change with zones modeling - Capture specifications and analysis context at preliminary design stage - Respect company's standards