What are Crosby`s 14 Steps?

advertisement

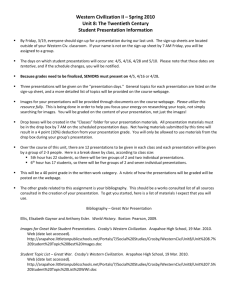

Crosby’s 14 Steps Brin Tracy Marriott School of Management What Will Be Covered 1. What are Crosby’s 14 Steps? 2. Brainstorming Exercise: How Can This Tool be Used in Your Organization? 3. Explanation of Crosby’s 14 Steps 4. How Crosby’s 14 Steps Work 5. Real World Example: GM Truck & Bus 6. An Exercise 7. Summary 8. Readings list What are Crosby’s 14 Steps? • • Adapted from chapter eight of Quality Is Free: The Art of Making Quality Certain (1979) A fourteen step program for quality improvement – – Top management involved Entire organization involved What are Crosby’s 14 Steps? • A “how-to” for management that provides an organization with a simple and organized method to initiating the quality improvement process and beginning the journey to worldclass quality What are Crosby’s 14 Steps? • “Focuses on long-term employee participation, not short-term motivational tactics.” - Crosby, Philip (1979) Crosby’s 14 Steps to Improvement Brainstorming Exercise: How can this tool be used in your organization? • Each person in the audience identify an area in the organization (process, product, service, etc.) that you feel needs improvement. (3 min) – Cycle times – Delivery times – Any wasteful or non-value added activities Foundation for Crosby’s 14 Steps Crosby’s absolutes of quality management: • Quality means conformance, not elegance. • There is no such thing as a quality problem. • There is no such thing as the economics of quality; it is always cheaper to do the job right the first time. • The only performance measurement is the cost of quality. • The only performance standard is Zero Defects. Nuts and Bolts 1. MANAGEMENT COMMITMENT - Top-level view on quality shown to all employees. 2. THE QUALITY IMPROVEMENT TEAM - To pursue the quality regime throughout the business. Nuts and Bolts 3. QUALITY MEASUREMENT - Analysis of business quality performance in a meaningful manner. 4. THE COST OF QUALITY - Make sure everyone in the business understands the need for a quality system, and the costs to the business if there is no quality system in place. Nuts and Bolts 5. QUALITY AWARENESS - Again make everyone in the business aware of the impact of quality systems. 6. CORRECTIVE ACTION - Ensure a system is in place for analyzing defects in the system and applying simple cause and effect analysis, to prevent re-occurrence. Nuts and Bolts 7. ZERO DEFECTS PLANNING - Look for business activities to which zero defect logic should be applied. 8. SUPERVISOR TRAINING - Get your supervisors trained in both quality logic and zero defect appreciation which they can apply to their business activities. Nuts and Bolts 9. ZERO DEFECTS DAY - A quality event by which all members of the effected section become aware that a change has taken place. 10. GOAL SETTING - Once a change has been implemented in a section of the business, the next step is to get the employees and supervisors in that section to set goals for improvement to bring about continuous improvement. Nuts and Bolts 11. ERROR CAUSE REMOVAL - Communication process by which management are made aware that set goals are difficult to achieve in order for either the goals to be reset or help given by management to achieve the goals. 12. RECOGNITION - Management must recognize the employees who participate in the quality schemes. Nuts and Bolts 13. QUALITY COUNCILS - Using both specialist knowledge and employee experiences to bring about a focused approach to business quality regime. 14. DO IT OVER AGAIN - Continuous improvement means starting from the beginning again and again. How It Works 14 1 13 2 12 3 11 4 10 5 9 6 8 7 Real World Example: GM Truck & Bus Background: • Responsible for the planning, engineering, manufacturing, and assembly of General Motors Trucks worldwide • They needed to develop a common direction for our quality process • They wanted the entire workforce to be aware and involved - (Hartman, 2002) Real World Example: GM Truck & Bus Implementing Crosby’s 14 Steps: • “In line with Step 2 of Crosby’s 14-step process, Truck & Bus implemented both a group quality improvement team and plant and staff quality improvement teams to run the quality improvement process.” - (Hartman, 2002) Real World Example: GM Truck & Bus Progress: • The quality improvement teams initially managed the “soft” or non-product areas covered in Crosby’s 14 steps, such as awareness and communication, quality education, cost of quality, and recognition. • The role of [their] quality improvement teams gradually shifted from “implementing [their] quality improvement process” to “being the driving force in improving the quality of all of [their] business processes.” - (Hartman, 2002) Real World Example: GM Truck & Bus Results: • “The 14-step process provided The Truck & Bus Group with the most defined, simple-to-follow road map for the initial legs of their quality journey.” • “Helped everyone focus on the quality of their business process and to understand their internal customer/supplier relationship. Every individual produces a product and has customers. Everyone must determine the requirements and satisfaction of their personal customers.” - (Hartman, 2002) An Exercise • Break into groups of four-six • The group discusses the identified items from the brainstorming session (6 min) – Choose one area that you feel needs the most improvement (i.e. causes the most problems, wastes time and resources, will make biggest impact) • Discuss as a class An Exercise Cont. • Split back into your groups and determine the following (8 min): – The costs to the business if there is no quality system in place – A corrective action that will prevent re-occurrence – A goal for improvement that will bring about continuous improvement • Discuss as a class Summary • Crosby’s program is designed to transform the quality culture of an organization • Helps involve everyone in the organization in the quality process • Crosby 14 Steps to quality improvement is a continuous process that will bring great rewards and benefits to your organization Summary • “Either you don't accept things that don't meet the requirements— or you find out whether the requirement is really what you need, but the business of ‘that's close enough’ has to go away.” ~Philip Crosby Readings List • • • • • • • • • Crosby, Philip (1979). Crosby’s 14 Steps to Improvement. New York: McGrawHill Crosby, Philip (1979). Quality is Free: The Art of Making Quality Certain. New York: McGraw‐Hill. Crosby, Philip (1984). Quality Without Tears. New York: McGraw‐Hill. Crosby, Philip (1988). The Eternally Successful Organization. New York: McGraw‐Hill. Crosby, Philip (1989). Let’s Talk Quality. New York: McGraw-Hill. Crosby, Philip (1994). Completeness: Quality for the 21st Century. Plume. Crosby, Philip (1996). Quality is Still Free. New York: McGraw-Hill. R W Hoyer, Brooke B Y Hoyer, Philip B Crosby, W Edwards Deming, et al. (2001) Quality Progress. Milwaukee: Vol. 34, Iss. 7. Hartman, Melissa (2002). Fundamental Concepts of Quality Improvement. Milwaukee: ASQ Quality Press.