Focus on Supplier - Parker

advertisement

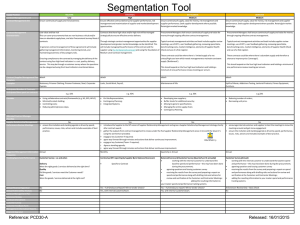

IAQG “Supply Chain Management Handbook” IAQG General Assembly York, North Yorkshire, UK Friday, October 22, 2010 Bill Schmiege Parker Hannifin Company Confidential 1 Content • Introduction to Supply Chain Management Handbook (SCMH) • SCMH content today and tomorrow • Accessing e-SCMH • Examples 2 Supply Chain Management Handbook (SCMH): • What is the SCMH ? – A collection of guidance materials, trainings, best practices for Suppliers • What are the Objectives of the SCMH? – Provide guidance material to help improve the “On Time and On Quality” performance through out the supply chain – Provide “how to” information for various Aerospace standards • Note - The e-SCMH is a web based toolbox with FREE access to suppliers Focus on “How” through SCMH QMS Inputs for new revision of 91XX 91xx 9131 9103 Requirements 9102 Providing guidance material and best practices on how to meet requirements and achieve objectives SCMH Guidance material, tools, training Supply Chain Management Handbook SCMH Leadership: – IAQG Mentor: Wayne Brown (Boeing) – AAQG (Americas): – Bill Schmiege (Parker Hannifin) – Larry Weng (Boeing) – APAQG (Asia Pacific): – Shuji Komori (FHI) – EAQG (Europe): – Christian Buck (Safran) – Bernard Lauras (Airbus) Supply Chain Management Handbook • SCMH contents have been developed by member companies of the IAQG and the document is structured to cover the entire product life cycle process: – Intended for use by companies at all levels of supply chain – Aligned with Product Life Cycle – Currently 16 sections published – Other sections “in work” or to be developed in the future Supply Chain Management Handbook Content Based on the Product Life Cycle 1. Sales, Master Scheduling & Sequencing • Master Scheduling 2. Contract Requirements & Flow Down 3. Design & Development • Requirements & Flow Down Templates • Special Requirements & Critical Items • Software Guidance (9115) 4. Suppliers sourcing selection & approval • Supplier Selection and Capability Assessment • Product Performance Detailed Assessment Checklists • Quality Aspects of New Product Development 5. Plant, material, skills, capacity planning & scheduling • Planning of Product Realization 6. Order Management and logistic (Internal & external) • Lean Assessment Tool • Order Management and logistic 9. Control of non conformities, corrective and preventive actions 10. Customer Support (Control of service operations) • Root Cause Analysis & Problem Solving • Counterfeit Part Prevention • Control of non conformities • MRO 7. Manufacturing and Inspection • 9103 Material for Key Characteristics • 9102 Material for First Article Inspection • Foreign Object Debris (FOD) 11. Business Management & Customer Sat. Monitoring • Work Transfer • Configuration Mgmt • Risk Management 8. Supplier operational management and product validation • Notification of Change Tool • Supplier Quality Mgt Basics • Subtier Supplier Management Appendices • 9100 Rev C Deployment Support • People Capability PCAP 001 • Link to IAGQ Dictionary • Preventive Action Available Work In Progress New Priorities 7 Recently Published topics (since last IAQG) • Foreign Object Debris (FOD) • Requirements & Flow-down update to 9100:2009 (Rev C) • Control of non conforming product interactive tutorial update to 9100: 2009 (Rev C) • Configuration Management (partial) • Special Requirements/Critical Items (partial) • Supplier selection capabilities assessment (maturity model) updated • Supplier Quality Management Basics • Risk Management Topics in final editing/publication Projects in Pre-editing for publication – Special Requirements Critical Items Awareness presentation (2nd part) – Configuration Management Awareness (2nd part) – Product Performance Detailed Assessment Checklists Active Writing Teams • Counterfeit/Unapproved Parts • SW guidance for 9115 • Quality Aspect of New Product Development • Preventive Action • Subtier Supplier Control Team in development • Master Scheduling, Planning, and Ordering • Securing Team Leader and members Future Topics • Contract Review • Contract Requirement Change Management (including verification of flowdown to subtier) • Contractual flowdown of requirements process (include visibility and application through quality plan) • Update/expand Variation Management material - simplify, add tools/templates. • Supplier approval process (including disapproval) • Assembly Work Instruction • Total Preventive Maintenance (TPM) Released improved SCMH Webpage • New SCMH format – rolled out 7/2/2010 • Improved accessibility and navigation • Searches engine • Quick link – drop down menus • Alpha listing Use and give us feedback ! “Link to SCMH” Easy access to SCMH http://www.iaqg.sae.org/scmh Free access via the IAQG Website. Easy access to SCMH Accept terms and conditions. Immediate and FREE access SCMH Home Page Example SCMH Material Foreign Object Debris (FOD) • FOD Program Procedure • FOD Training Module • Assessment Tool – three level of robustness • Printable and fillable on-line check sheets and forms Supplier Selection and Capability Assessment • Assessing Supplier Maturity to 11 Business Processes covering the entire product life cycle process • Five levels of maturity 1. Undefined and not capable 2. Defined and applied, but not 100% efficient or not applied everywhere in the company 3. Defined, applied and effective 4. Predictable 5. Optimized • Four domains assessed Process, People & Organization, Tools & Data, Performance Metrics • Results synthesis - show strengths and weaknesses Areas of potential Supplier Development if deemed necessary Work Transfer Management • Work Transfer Management procedure • 4 gate review process • Fillable forms for: – Each gate review – Project Proposal – Risk Assessment & Business Case – Product Readiness Review Variation Management of Key Characteristics (9103) • Guidance material aligned to 9103 • Seven Stage process • Training tutorial First Article Inspection (FAI) • Guidance material aligned to 9102 • Includes: – FAI FAQ – FAI checklist – Step by step instruction for filling out 9102 FAI reporting forms » Form 1 - Part Number Accountability » Form 2 - Product Accountability » Form 3 - Characteristic Accountability, Verification and Compatibility Evaluation SCMH Summary • The SCMH is a collection of guidance materials, training packages, and best practices for suppliers. • The objective of the SCMH initiative is to improve the “On Time and On Quality” performance through out the supply chain • Provides “how to” information for various Aerospace Standards requirements. – Guidance, not a requirement or auditable checklist. • Free - may be adopted (and adapted) by any organization to improve quality and delivery performance. • Continues to improve and provide value to the Supply Chain through user feedback http://www.iaqg.sae.org/iaqg http://www.iaqg.sae.org/scmh Questions?