Production methods

advertisement

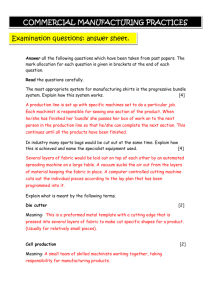

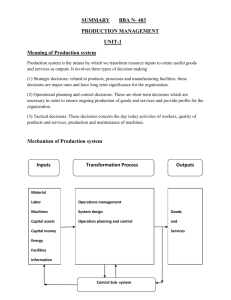

Production methods Mass production Industrial practices Industrial practices are designed to ensure that quality products are manufactured efficiently at a profit. They involve designers working together with clients and manufacturers, all of whom need to keep the needs of the consumer in mind. Roles in industrial practice The client The client identifies the need for a product through market research and uses this to provide a design brief for the designer. They set production deadlines and the price of the product. The client is usually a manufacturer or retailer. The designer The designer works to the design brief and researches market trends, fabrics and processes, taking into account any relevant societal, cultural, moral, environmental or safety issues. They produce a design specification, product costings, and help plan manufacturing. The manufacturer The manufacturer uses models or prototypes made by the designer, and works out the most efficient way of manufacturing the product. They produce a production plan and a work schedule. During manufacture they aim to keep material and labour costs down, while producing a high-quality, safe product on schedule in a safe environment. The user or consumer The user or consumer demands a product that meets their requirements: a highquality, value-for-money and safe product Mass production ( flow production) Manufacture of large quantities of products Low production costs All finished products are the same Production line workers only do repetitive tasks Mass production began in Detroit in 1914 when Henry Ford discovered that a moving assembly line using interchangeable parts could radically reduce the cost of making motor cars. He sold 18m Model T Fords, transforming America into the first carowning democracy, at a price that dropped from $600 to $250 over 15 years. Mass production was unpleasant work, with high turnover. To retain his unskilled workforce, Ford doubled their wages to $5 per day - justified by higher productivity. Mass production Mass production of textiles products in a factory Mass production is the industrial-scale manufacture of large quantities of products, usually on a production line. Standardised production methods mean it is suitable for products that rarely need to be redesigned. Mass production is used for products that are needed in very large numbers, eg socks or jeans. Often, products are made overseas where labour costs are lower. Automated mass productiopn One off production One-off production In one-off production a single product is designed and made to a client's specification. Labour and material costs are high, and a high level of design and manufacturing skills are needed. An example of one-off production would be a made-to-measure wedding dress. Batch production Batch production In batch production set quantities of a product are manufactured to order. Batch production requires a high level of design, pattern making and sampling skills. Materials are cost-effective and manufacturing costs are lower than oneoff production Just-in-time manufacturing is when materials are ordered so they arrive just as they are needed. Cell production Cell production has the flow production line split into a number of self-contained units. Each team or ‘cell’ is responsible for a significant part of the finished article and, rather than each person only carrying out only one very specific task, team members are skilled at a number of roles, so it provides a means for job rotation and team working Systems in textile production Preparation stage: the amount of materials to buy-in. Preparation of garment patterns, templates and lay plans. Processing stage: fabric spreading, cutting, labelling and bundling of fabric pieces. Assembly stage: instructions for fusing, joining and pressing the separate parts. Finishing stage: instructions for decorative/functional finishing and final pressing. Packaging stage: how to label, hang, fold and cover the product ready for transport. Systems and subsystems In a production system, a number of different processes or subsystems take place at the same time. Examples of subsystems Lay-planning: this involves laying out pattern pieces of a fabric to work out the quantity and cost of material. Costing: this involves estimating how much each product costs to make, including materials, labour, rent and energy costs. Quality control: this involves the checks for quality that take place at all stages. Elementary flow chart symbols Simple flow chart for cruise control in a motor vehicle