industrial practises

advertisement

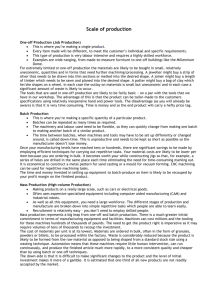

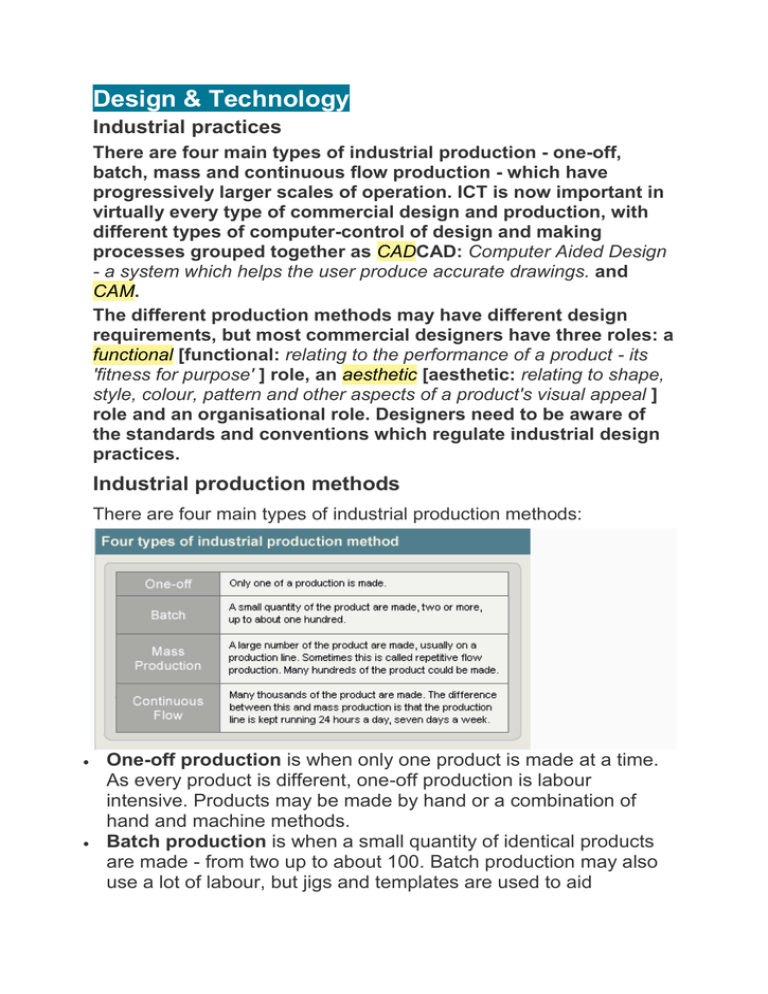

Design & Technology Industrial practices There are four main types of industrial production - one-off, batch, mass and continuous flow production - which have progressively larger scales of operation. ICT is now important in virtually every type of commercial design and production, with different types of computer-control of design and making processes grouped together as CADCAD: Computer Aided Design - a system which helps the user produce accurate drawings. and CAM. The different production methods may have different design requirements, but most commercial designers have three roles: a functional [functional: relating to the performance of a product - its 'fitness for purpose' ] role, an aesthetic [aesthetic: relating to shape, style, colour, pattern and other aspects of a product's visual appeal ] role and an organisational role. Designers need to be aware of the standards and conventions which regulate industrial design practices. Industrial production methods There are four main types of industrial production methods: One-off production is when only one product is made at a time. As every product is different, one-off production is labour intensive. Products may be made by hand or a combination of hand and machine methods. Batch production is when a small quantity of identical products are made - from two up to about 100. Batch production may also use a lot of labour, but jigs and templates are used to aid production. Batches of the product can be made as often as required. Often the machines can be easily changed to produce a batch of a different product. Mass or repetitive flow production is when hundreds of identical products are made, usually on a production line. Mass production often involves the assembly of a number of sub-assemblies of individual components. Some parts may be bought from other companies. There is usually some automation of tasks (eg by using Computer Numerical Control [Computer Numerical Control: the use of computers to control cutting and shaping machines. CNC for short ] machines) and this enables a smaller number of workers to ouput more products. Continuous flow production is when many thousands of copies of identical products are made. The difference between this and mass production is that the production line is kept running 24 hours a day, seven days a week to maximise production and eliminate the extra costs of starting and stopping the production process. The process is highly automated and few workers are required. ICT in industry Computer-aided design and making are nowadays commonplace in industry. ICT is most often used in mass production, as computer control makes it possible to produce many identical items very quickly. But ICT is also useful in small batch and even one-off work, as computer control also enables complicated shapes to be produced more accurately than by hand. The box summarises the many roles of ICT in industry: Data can be stored electronically and retrieved easily. Designs can be modelled on-screen and viewed from any angle. Reaction to outside forces, such as wind flow and pressure can be modelled. Designs can be quickly altered. "Zoom" facilities can allow for the whole product or one detail to be easily seen. Libraries of standard components can be stored electronically and integrated into new designs. Control sequences can be simulated before working on the actual material. CNC (Computer Numerical Control) manufacturing is usually more accurate. You need to know and understand a number of terms used to describe aspects of ICT in design and production. They are: CAD - Computer-aided design CAM - Computer-aided manufacturing CIM - Computer-integrated manufacturing FMS - Flexible manufacturing systems CNC - Computer numerical control PDM - Product data management CADMAT - Computer-aided design, manufacturing and testing Industrial design Different production methods - eg, one-off, batch, and mass or continuous production - have somewhat different design requirements, related to the differences between types of product, client expectation, and the scale of operation. In particular there are differences in the relationship between the designer and the client [client: person or organisation that wants a product manufactured - eg a retailer. ], who gives the designer his or her brief. In one-off [one-off: individual. Individual products may be made by hand or a combination of hand and machine methods. As every product is different, one-off production is labour intensive. ]production the designer is frequently the maker as well. The client is usually the end-user of the product, and will have high expectations about the quality of the product. The designer will nearly always have a direct relationship with the client, so it is essential that the designer is fully conversant with the end-user's requirements. In batch [batch: production method for making a small quantity (between two and about 100) identical products. ] production the process of designing is more formalised, but the number of people involved may still be quite small. The client may be the user, but is more likely to be another company who sell the product. The designer will not necessarily have any contact with the end-user of the product. In mass [mass: production method for making hundreds of identical products, usually on a production line. Also called repetitive flow production. ] and continuous [continuous: production method for making many thousands of identical products. The difference between this and mass production is that the production line is kept running 24 hours a day, seven days a week. ] flow production the processes of designing and manufacturing are much more formal. Making of changes can become slower. There is little or no contact between the designer and the client. The designer is therefore dependent on other people feeding back the end-users' views. The role of the designer Commercial designers have a threefold role: A functional role, which involves making decisions about function, purpose, materials, systems and control, and methods of joining, constructing and finishing the product. An aesthetic [aesthetic: relating to shape, style, colour, pattern and other aspects of a product's visual appeal ] role, which involves making decisions on things like shape and form, colour, texture, pattern, and decoration. And An organisational role - for example helping to source materials, organise the manufacturing process, and make decisions about the marketing [marketing: The activity of transferring goods from producers to consumers - most commonly marketing is used to refer to advertising. ] of the product. Marketing and advertising Marketing is about understanding the potential consumers of the product: who are they, and what exactly do they want? Answering these questions will usually involve doing market researchmarket research: Market research is the gathering of data or information concerning consumer opinions about a product or service. Advertising is about telling people about a new or improved product, and/or persuading them to buy it. Advertising can take many forms, including: ads placed in newspapers and magazines posters on hoardings, buses, stations etc tv and radio commercials telephone advertising direct mail (ads sent out in the form of leaflets, mail shots, emails and texts) online advertising Laws and standards Industrial design and manufacturing processes of products must conform with the following laws [laws: formal rules adopted by Parliament and enforced by government ] and standards [standards: guidelines or specifications which are widely agreed and commonly accepted, but do not necessarily have the force of law ], designed to protect consumers from inferior, misleading or unsafe goods and services: Fair Trading Act [Fair Trading Act: law which protects consumers where the following are not acting in their interest: monopolies, where businesses have 25 percent of the market, mergers, where two companies plan to join together, and rogue traders, where the Office of Fair Trading (OFT) will take action against persistent offenders. In 2003 the Enterprise Act replaced the Fair Trading Act. ] Consumer Protection Act [Consumer Protection Act: law which protects the public by: prohibiting the manufacture and supply of unsafe goods, making the maker or seller of defective products pay for damage it causes and allows councils to seize or suspend the sale unsafe goods. ] Trade Descriptions Act [Trade Descriptions Act: law which makes it an offence for a trader to make false or misleading statements about goods or services. The Act carries criminal penalties and is enforced by local authorities' Trading Standards Officers. ] Safety standards set by the British Standards Institute (BSI) and the European Community (EC) Drawing conventions Conventions are ways of doing things - for example, technical drawings - which conform to a common standard. Using conventions saves time and ensures that a drawing means the same thing to anyone who sees it. The BSI standard for drawings is BS8888. When doing a drawing, you should always use the relevant conventional symbols. The illustration below shows two drawings conforming to BS8888 specifications. BS8888 also sets out how measurements should be written down on a drawing. It specifies that dimensions should be written outside the drawing, with extension lines and dimension lines. Extension lines are parallel lines which extend out from two points on the drawing between which a dimension needs to be shown. (Remember to add a small break where the extension line meets the drawing.) Dimension lines are drawn with an arrow on either end between two extension lines, with the dimension written alongside. (Don't forget to state the unit of measurement.) Now try a Test Bite Back to Revision Bite