Facility Location Planning

advertisement

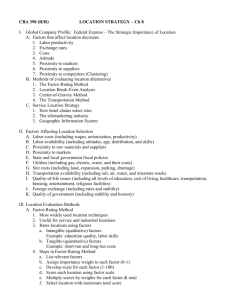

Facility Location Planning Location Planning • Interrelated facility planning decisions: 1. 2. Location of facilities: geographic placement Number of facilities: facility types (manufacturing plants, distribution centers, retail outlets, etc.) which make up distribution network Size of facilities (capacity): refers to the overall cubic feet and throughput (volume) rate which constrains all future facility operations. 3. This must also consider the layout. 4. Allocation of customers to facilities: order processing and fulfillment • • Important factors affecting the decision include: proximity, facility volume, transportation costs, customer importance, etc. Facility location dependent upon objective(s) Strategic Importance 1. Capital investment (machinery, technology, land, buildings, etc.) 2. Long-term commitment 3. Impact on costs (operating efficiency) 4. Numerous criteria Location Planning Process 1. Each problem is unique 2. Scope of problem: Two levels • Level 1: Macro (national and regional), identifies a general location based upon primary cost, customer service standards, technological constraints, and dominant location factors; many possible locations eliminated at this level • (2) Level 2: Micro (local and specific), identifies an exact site within the general location; incorporates considerations which are not easily quantifiable 3. “Satisficing” solutions Facility Location Methods of Analysis 1. Simple cost formulation combined with a complex optimization procedure 2. Complex cost model combined with a simple heuristic method to minimize the cost function Single-Site Facility Location Problems 1. Hoover’s Strategies: e.g., market-oriented, production-oriented 2. Cost-Volume-Profit (Breakeven) Analysis 3. Transportation Method of Linear Programming 4. Center of Gravity Approach 5. Others? E.g., Payback, NPV, IRR, etc. Multiple-Site Facility Locations • More complex decision-making problem due to its interdependence; large number of potential logistic system configurations; yet more realistic and more common as even many small firms have more than one facility. • Some methods of analysis: optimization (e.g., LP), simulation methods, heuristic methods Linear Scoring Rule (rating scale or weighted checklist) • Integrates both quantitative and qualitative factors • LSR Concerns 1. weights are subjective and solution sensitive 2. scores are subjective and solution sensitive 3. all factors considered? • Example A paint manufacturer would like to locate a retail store. A list of important location factors is presented below. Factor weights are assigned a number from 1 to 10 according to their relative importance of each factor (10 being most important). Each location factor is scored on a scale from 1 to 10 (10 representing the most favorable status). LSR Example Factor Weight 8 5 8 7 6 Location Factors Proximity to competition Rent/lease considerations Parking Space Proximity to complementary stores Modernity of store space Factor Weighted Score Score 5 40 3 15 10 80 8 56 9 54 Total Score: 245