David Bivens, Caitlin Byler, Rachel Douglas, & Kaycee Wilson

advertisement

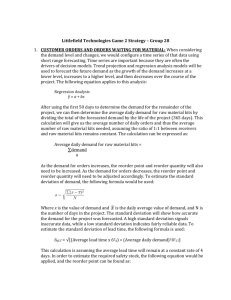

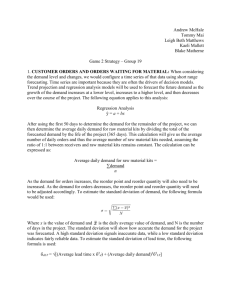

Reducing Stock-Outs in MD Anderson Cancer Center’s Outpatient Clinics David Bivens, Caitlin Byler, Rachel Douglas, & Kaycee Wilson Speaker: Kaycee Wilson, Quality Engineer Supply Availability Project Teams Steering Committee Office of Performance Improvement Materials Management Melanoma & Skin Center Susan Ferguson David Bivens Antonio Odems Mimi Brooks Cynthia Powers Rachel Douglas Pete Verdone Oguna Taylor Jeremy Viles Kaycee Wilson John Morgan Cynarra Osborn Byron Main Caitlin Byler Travis King Oletha Jones Carl Crofton Rosa Rodriguez Jimmy Sherman Current Inventory Management Process Clinic Close 1 Collect Supplies from Staging Area Clinic Open Note: Items Received were Ordered Night Before 2 5 Deliver Supplies to each Par and Restock Supplies are Used Note: Those orders arrive the next evening 4 Reorder Par less inventory on hand by putting the count left in the bin in the handheld. 3 Identify Supplies that need to be Reordered New Supply Process Objectives Quantitative Objectives • Minimize: Stock-outs ( Patients Denied Care ) Subject to: • Available Space • Available Labor • Inventory Cost Qualitative Objectives • Ease of Use • Ease of Implementation • Ease of Sustainment Process Observation and Analysis • Four inventory process areas were identified for improvement efforts • • • • Level Setting Reorder Signal Reorder Quantity Business Roles Baseline Analysis • Level Setting Pilot Solution Level Setting • There are two numbers important for level setting • Reorder Point • Based on a one day delay between order and actual delivery • Calculated with historical ordering data by material reps • Calculated based on items pulled from the warehouse • Derived using statistical analysis yielding stock-out risk • PAR Level • Based on current workload 1. PAR Level 2. Reorder Point Baseline Analysis • Reorder Signaling Pilot Solution for Reorder Signaling Baseline Analysis • Order Quantities The materials rep will have to put the number remaining in the bin in the handheld. Pilot Solution Order Quantities • Always order the same amount Always order about ½ bin size Baseline Analysis • Business Roles • Materials Management • Responsible for responding to clinic requests for par changes • Responsible for order and delivery of supplies • Clinics • Responsible for setting the inventory level of each item Daily Clinic Usage 1 Pull the card when the supply level is at or below the tapeline Place the card in the low stock bin 1 Low Stock Pull the card when you use the item 1 Nightly Replenishment 2 2 Deliver supplies & make sure that the waterline holds the “reorder point” quantity 7 Put all cards in the ordered bin back on delivered item bins 3 4 Pull out all of the cards in the “low stock” bin Scan the barcode on the back of the card and enter the handheld # in handheld. If you have to pull the quantity from the warehouse, pull the warehouse # amount ! Note Place scanned cards in the “ordered” bin Pilot Resupply Process and Business Roles Back of Card PAR Setup Process and Business Roles 3 Materials Management Team Clinical Team Approve/Disapprove suggested removal of items 1 2 Reset levels 8 Create Stock Cards Request approval for removal of low usage items from Par (Red Tagging) 4 Put in waterlines and adjust preset levels 7 5 Reorganize closet with nursing feedback 6 Relabel Reset Par in handhelds **Blue boxes represent steps requiring tool created by OPI P59 Melanoma and Skin Center Baseline P59 Melanoma and Skin Center Pilot Setup Tapeline Setting & Fixed Ordering Methodology • (R,s,Q) Model Undershoot Risk period Figure 1. Illustration of undershoot in an (𝑹, 𝒔, 𝑸) model where 𝒔 = 𝑸, 𝑹 = 𝟏, 𝒂𝒏𝒅 𝑳 = 𝟏. Tapeline Setting & Fixed Ordering Methodology • Reorder Point 99.7% 95% Area that supply usage is less than average Stock-out area 68% Tapeline Setting & Fixed Ordering Methodology • Undershoot ** 𝜇𝑢𝑛𝑑𝑒𝑟𝑠ℎ𝑜𝑜𝑡 2 𝜇𝑟𝑒𝑣𝑖𝑒𝑤 2𝜇𝑟𝑒𝑣𝑖𝑒𝑤 − • Fixed Order Quantity 𝑄 𝑆 − 𝑠 + 𝜇𝑢𝑛𝑑𝑒𝑟𝑠ℎ𝑜𝑜𝑡 **See References Slide 1 2 Reorder Point Setting & Fixed Ordering Simulation Stock Card Template Summary of Assumptions • Objective – stock-out minimization • Carry a minimum of two days on hand • Constraints – labor, space, and budget • Increase the days on hand to meet labor standards • Distribution of daily demand - normal • Set reorder points according to a normal distribution • Daily supply usage • Estimate daily demand using work days between ordering instances Pilot Issues Future Work • Pedi – Child & Adolescent Center • Cardiopulmonary Center • Breast Center • Leukemia Center • Clinical & Translational Research Center References Junior, M.L. and M.G. Filho. 2010. Variations of the kanban system: Literature review and classification. Int. J. Production Economics, 125: 13-21. Chan, F.T.S. 2001. Effect of kanban size on just-in-time manufacturing systems. Journal of Materials Processing Technology, 116: 146-160. Kumar, C.S. and R. Panneerselvam. 2007. Literature review of JIT-KANBAN system. Int. J. Adv Manuf Technol, 32: 393408. Bijvank, M. and I. Vis. 2011. Lost-sales inventory theory: A review. European Journal of Operational Research, 215: 1-13. Johansen, S.G. and R.M. Hill. 2000. The (r,Q) control of a periodic-review inventory system with continuous demand and lost sales. Int. J. of Production Economics, 68: 279-286. Bijvank, M. and I. Vis. 2012. Inventory control for point-of-use locations in hospitals. Journal of the Operational Research Society, 63: 497-510. Baganha, M.P., D.F. Pyke, and G. Ferrer. 1996. The undershoot of the reorder point: Tests of an approximation. Int. J. of Production Economics, 45: 311-320. Silver, E.A., D.F. Pyke, and R. Peterson. 1998. Inventory Management and Production Planning and Scheduling. 3rd Edition. Hoboken, NJ: John Wiley & Sons.