Presentation slides - Jobs for the Future

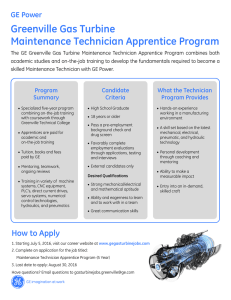

advertisement

Industrial Manufacturing Technician Apprenticeship Partnership among AFL-CIO, WRTP, HRDI, and JFF Funded by $3,000,000 H1b grant to – Develop apprenticeship curriculum – Obtain state and federal recognition as registered apprenticeship – Enroll 160 registered apprentices – Complete 130 journey IMTs & Innovative Apprenticeship Design 1. Hybrid Competency- based apprenticeship 2736 hours on-the-job learning 264 hours related classroom instruction • OR Demonstrated skill attainment according to Job Book Pass 4 MSSC CPT tests, OSHA 10, First Aid/CPR certifications, and complete shop math, communication, and train the trainer courses 2. Online learning option 3. Flexible scheduling 2. Apprenticeship Navigators & What is an Industrial Manufacturing Technician? Entry level industrial manufacturing technicians • operate industrial production related equipment, • work with manufacturing related tools, and • perform work processes related to a wide variety of manufacturing settings. Industrial manufacturing technician apprentices will learn • To set up, operate, monitor, and control production equipment. • To help improve manufacturing processes and schedules to meet customer requirements. • Understand the manufacturing business as a system that integrates multiple disciplines, processes, and stakeholders. • Manage raw materials/consumables. & The IMT Curriculum Industrial Manufacturing Technician Apprentice 1 • 96 hours • Orientation to the trade and manufacturing, and the MSSC safety module, MSSC quality module, OSHA 10 certification, blueprint reading, visual inspection, measurement and first aid & CPR training. 50-420-711 • Mathematics for the Machine Trades • 32 hours • Applied mathematics review of basic arithmetic; basic algebra; applications, based on geometry; right triangle trigonometry, oblique angle trigonometry and compound angles. & The IMT Related Curriculum Industrial Manufacturing Technician Apprentice 2 • 96 hours • MSSC manufacturing processes and production and maintenance awareness modules, along with communication, lean manufacturing, problem solving, and frontline leadership. Manufacturing related concepts will be applied to a variety of industrial setting. The course wraps-up with an examination of emerging trends and technologies, and future directions for manufacturing. Communications for Apprentices • 32 hours • Basic communication concepts relating to the workplace, including giving instructions, writing a technical memo, and explaining a technical process. Throughout the course the apprentice will brainstorm, write, edit, revise, and use one-on-one communication delivery in a small group utilizing information which the apprentice brings from the workplace. & The IMT Related Curriculum Transition to Trainer: Your Role as a Journey Worker • 8 hours • In this workshop apprentices are introduced to a new set of basic tools--the tools of a jobsite trainer. Apprentices explore the skills that are necessary to be an effective trainer, discover how to deliver hands-on training, and examine the process for giving useful feedback. During the workshop apprentices build a Training Toolkit to take back to the job. This course prepares journey level workers and supervisors to pass on their knowledge of the trade. & IMT On-the-Job Learning Competencies • • • • • • • • • • • • Protect self and other workers from accidents and injuries 100 hours Operate production equipment 1000 hours Produce quality product 500 hours Interpret technical information 200 hours Measure and inspect work using mechanical tools and testing equipment 200 hours Demonstrate knowledge of routine equipment maintenance 100 hours Demonstrate knowledge of inventory and material processes 100 hours Demonstrate knowledge of trends and the current state of the business. 100 hours Demonstrate continuous improvement 100 hours Set-up production equipment 200 hours Local Options 138 hours & & &