Logistics_Jorge Leon Bello

advertisement

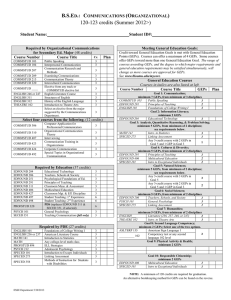

Famosa S.A. Full Speed Supply Chain Jorge León Bello__Master GEPS The company Company name: Famosa S.A. Location: Spain, Onil (Alicante) Product offered: Toy industry sector (games, dolls, soft toys, puzzles, toys for babies, etc.) Activity: Toy manufacturer and distribution company Two main production locations: China and Spain Employees: 700 Jorge León Bello__Master GEPS 2 Logistics factors at Famosa Toys are strongly season products: sales are concentrated between 3 or 4 months. Toys life cycles are very short: arrive at the sales point at the beginning of October and have become obsolete by the end of December. Manufacturing process needs to be “stock to order” which implies high risks in stocking inventory. Since China is its largest supplier and lead times are long, Famosa is dependent on the intensive use of forecasting. Jorge León Bello__Master GEPS 3 Problem Description IMBALANCED SUPPLY CHAIN: In 2003 the company could not deliver orders effectively due to stock outs, ignorance of the existence of orders, lack of warehouse management and control tools, etc. Jorge León Bello__Master GEPS 4 Problem Description Not structured production plan. Operational and logistics costs were too high. High level of capacity with huge semi-finished inventories. Products suffered high rates of obsolescence. Outsourcing in China used only as a source of components; products were still finished in Spain. Production in Spain gave flexibility but incurred high cost inefficiency. Distribution carried out from a single point only. Dispatch of products packed loose, without using pallets. Jorge León Bello__Master GEPS 5 The solution REDESIGN OF THE SUPPLY CHAIN: Changes in Organization and Information Technologies Reactive planning processes Collaborative planning with China Total redesign of distribution network Jorge León Bello__Master GEPS 6 Changes in Organization and Information Technologies Creation of and independent organization to manage a global and integrated supply chain to became more agile and capable in decision making. Integration of the procurement process into operation management moving from a simple price negotiation to negotiation of business rules. Integration of the operations in China into the company’s operations management, to improve quality and the reliability of production planning. Jorge León Bello__Master GEPS 7 Reactive Planning Processes The main objective was to reduce the variability of forecasting accuracy due to market uncertainty. This involved the creation of a planning department and transformation of speculative capacity (which involved purchase orders to enlarge capacity which ignored customer demand) into reactive capacity (which is more reliable). Adaptation of the supply chain to the production cycles of the suppliers in China. Jorge León Bello__Master GEPS 8 Reactive Planning Processes Lowering the lead time of products classified as very important, to permit product to be launched with significant changes implemented as late as possible. Giving priority to launch products which have a lower impact if forecasting proves to be wrong. Rewarding customers who confirm their purchasing intentions in advance. Jorge León Bello__Master GEPS 9 Collaborative Planning with China Famosa decided to produce 80% of its end product in China. The company’s relationships with suppliers are close: Famosa carries out production planning, and negotiates a Master Production Schedule with its given supplier, which launch its on Material Requirements Planning. Famosa has at its disposal the capacity necessary during peak seasons and is able to postpone loading through a more efficient planning and negotiations process. Jorge León Bello__Master GEPS 10 Distribution Network Redesign IMPLEMENTATION OF CENTRAL AND REGIONAL DC´s: Goods are dispatched direct from the DC in China to the market and to the central DC in Spain. Some goods are also dispatched from Onil (Alicante) to important customers, and small orders from Madrid. Famosa operates warehouses in all the principal European markets. Jorge León Bello__Master GEPS 11 Distribution Network Redesign CREATION OF A CONSOLIDATION CENTER IN CHINA: The objective was to take advantage of logistics and fiscal benefits, including the potential of consolidating products from different suppliers. The supply chain consolidation center is an export bonded warehouse. Jorge León Bello__Master GEPS 12 Distribution Network Redesign ADAPTATION OF LOGISTICS PROCESSES: Adaptation of logistics processes to consumer goods sector standards: coding and labeling, Electronic Data Interchange EDI messages, barcodes and RFID in SAP and the use of pallets. Jorge León Bello__Master GEPS 13 Thanks for you attention! Jorge León Bello__Master GEPS 14