SUPPLY CHAIN MANAGEMENT (SCM)

advertisement

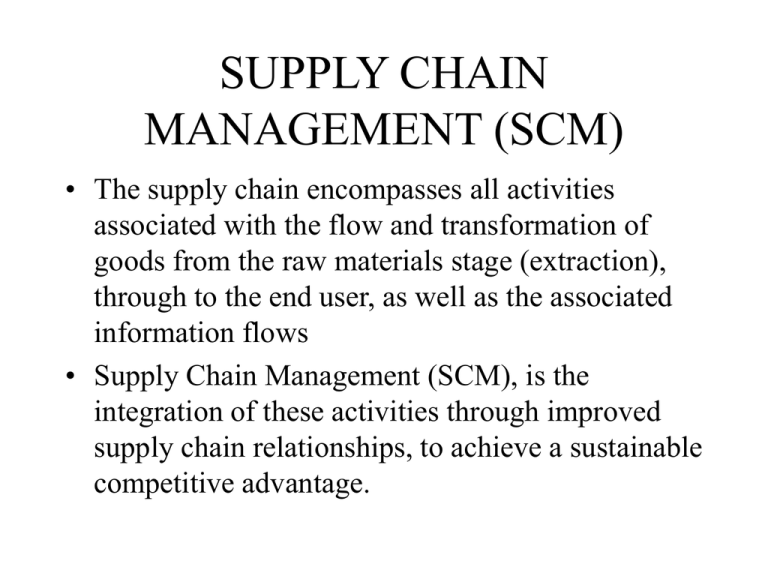

SUPPLY CHAIN MANAGEMENT (SCM) • The supply chain encompasses all activities associated with the flow and transformation of goods from the raw materials stage (extraction), through to the end user, as well as the associated information flows • Supply Chain Management (SCM), is the integration of these activities through improved supply chain relationships, to achieve a sustainable competitive advantage. SCM includes: • INTERNAL FUNCTIONS – Order processing, production scheduling, materials requirements planning (MRP), etc. • MANAGEMENT OF EXTERNAL UPSTREAM SUPPLY CHAIN – Planning, organizing, scheduling purchases; maintaining supplier relationships, etc • MANAGEMENT OF EXTERNAL DOWNSTREAM SUPPLY CHAIN – Physical distribution, distribution network, etc INFORMATION SYSTEMS AND SCM • • • • • • • Centralized coordination of information Total logistics management – integrating.. Order change --- impacts all functions Global transportation visibility Global inventory visibility Global sourcing visibility Intercompany information access INFORMATION SYSTEMS…. • Data interchange – between affiliates and non affiliates • Data capture -- data acquisition & tracking • Transformation of business from within – employees see “big picture” • Improvement in supplier-customer relationships INVENTORY AND SCM • INVENTORY • • • Becoming a time-based competitor – (some buzzwords) • Throughput time reduction • Delivery speed • Fast cycle capability • Quick response or resupply time • Lead time reduction • Time compression Results in less inventory Often better quality • SUPPLY CHAIN RELATIONSHIPS – Traditional adversarial relationship – Current closer relationship CHALLENGES FACING SCM • INFORMATION – Often not available > Bullwhip effect – Members often don’t share • INVENTORY MANAGEMENT – – – – – International borders Weather Poor communication Human error >>Complex and demanding • ESTABLISHING TRUST – Conflict management